Special micro motor fixing device

A technology of micro motors and fixing devices, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of no vibration reduction, loose fixing devices, single motor fixing methods, etc., and achieve the effect of reducing service life and avoiding loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

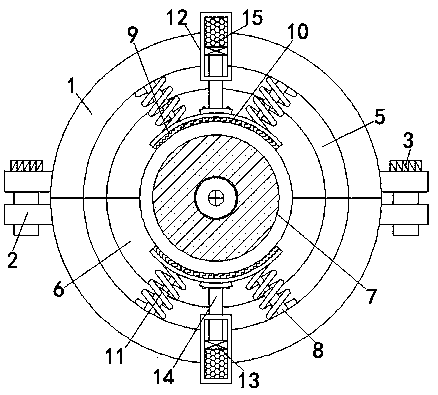

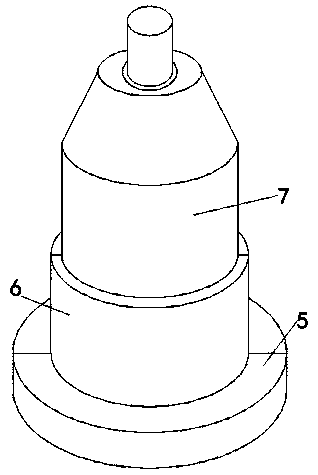

[0016] Embodiment 1: as figure 1 with figure 2 As shown, a special micro-motor fixing device includes two fixing covers 1, the left and right sides of the two fixing covers 1 are fixedly equipped with fixing blocks 2, and the two fixing blocks 2 on the same side are all connected by threaded threads. The rods 3 are fixedly connected, and the insides of the two fixed blocks 2 on the same side are provided with thread grooves matching the threaded rods 3, and the fixed blocks 2 are cuboid, and the inside of the fixed cover 1 is fixedly equipped with a base 5, and the front of the base 5 Mounting seat 6 is fixedly installed on the surface, both base 5 and mounting seat 6 are semi-cylindrical, and the combination of two bases 5 is a hollow cylinder, and the combination of two mounting seats 6 is a hollow cylinder. A motor 7 is installed in the room, and the model of the motor 7 can be 5IK90RGN. Two telescopic rods 8 are fixedly installed on the opposite surfaces of the two fixed...

Embodiment 2

[0017] Embodiment 2: as figure 1 with figure 2 As shown, a special micro-motor fixing device includes two fixed covers 1, the left and right sides of the two fixed covers 1 are fixed with fixed blocks 2, and the two fixed blocks 2 on the same side pass through The threaded rods 3 that are threaded are fixedly connected, the inside of the fixed cover 1 is fixedly installed with a base 5, the front surface of the base 5 is fixedly installed with a mounting base 6, and a motor 7 is movably installed between the two mounting bases 6 Two telescopic rods 8 are fixedly installed on the opposite surfaces of the two fixed covers 1, and the ends of the two telescopic rods 8 on the same side away from the fixed cover 1 are fixedly connected to the fixed sleeve 9, and the two telescopic rods 8 are fixedly connected to the fixed cover 9. The opposite surface of the fixed cover 9 is fixedly installed with a rubber cover 10 that is movably connected with the motor 7, and there are two spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com