A Method for Measuring Wave Dimensions of Three-lobed Outer Raceway of Bearing

A technology of three-lobe wave and outer raceway, which is applied in the field of geometric quantity measurement and dimension measurement, can solve the problems of three-lobe wave outer raceway bearing waveform size measurement, etc., so as to reduce uncertainty components, uniform force, and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

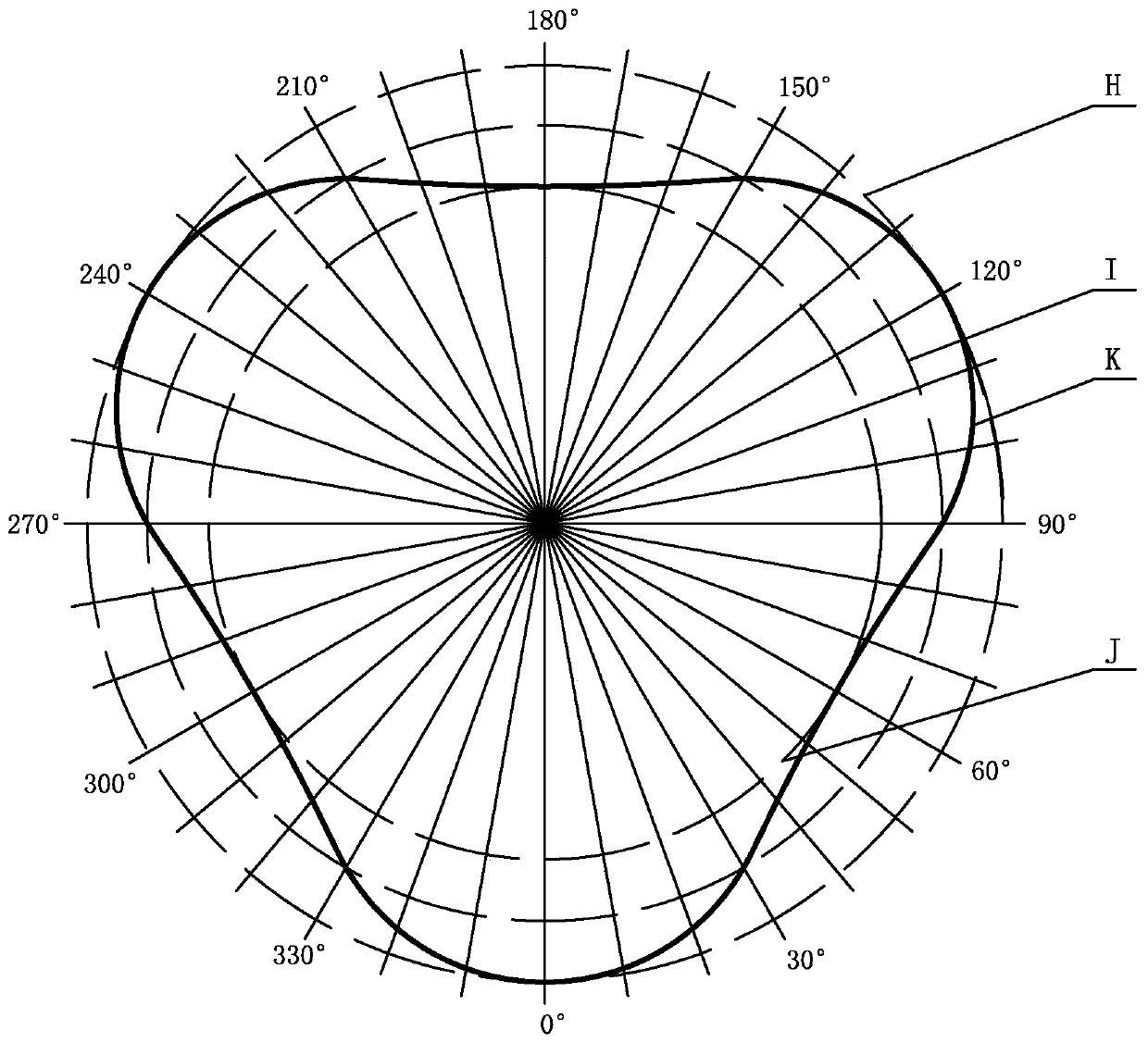

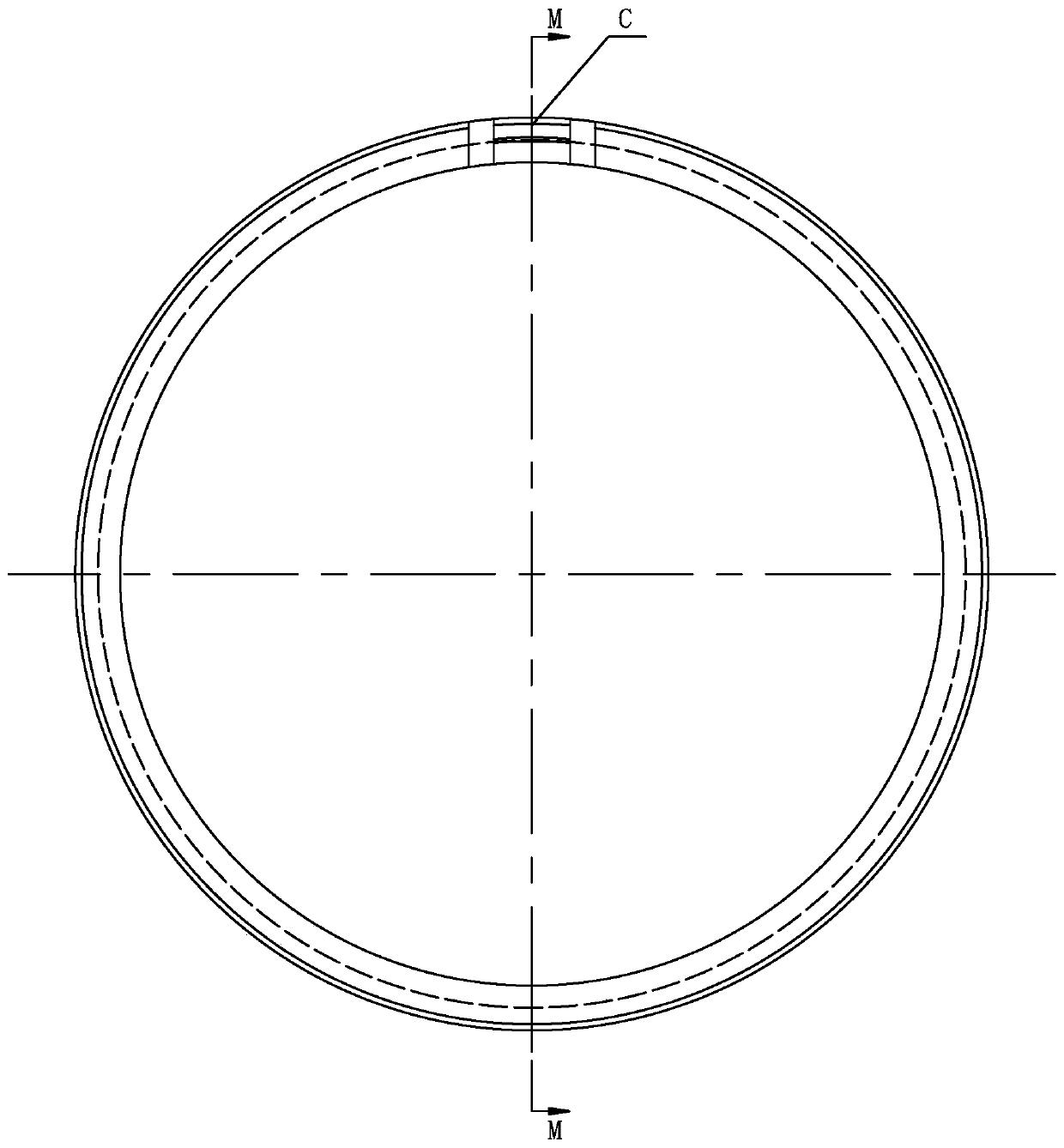

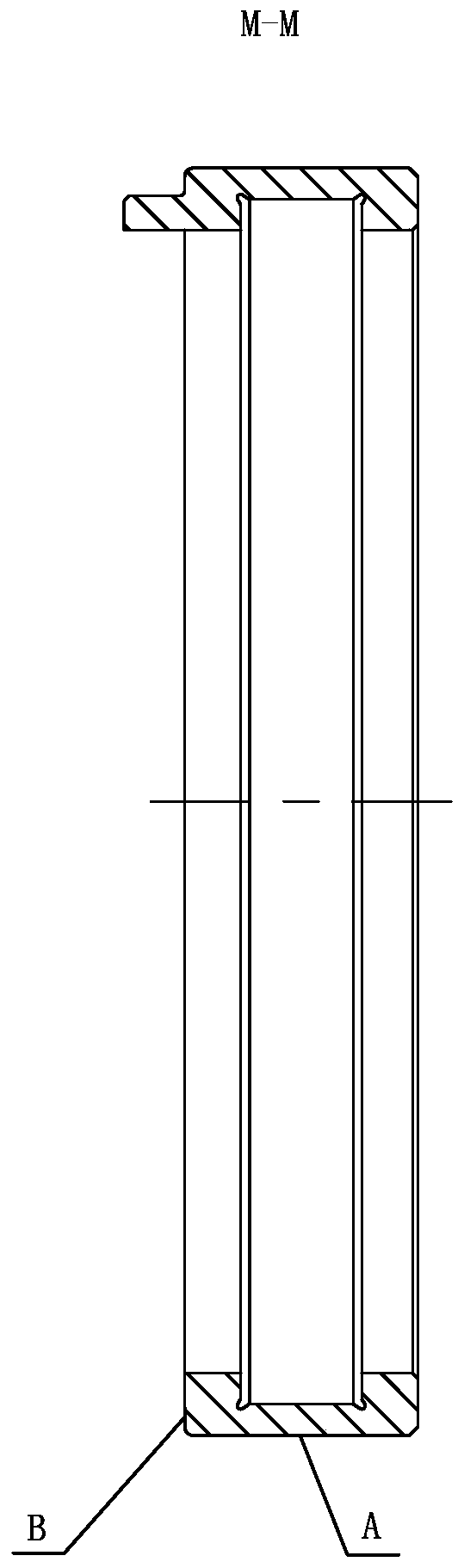

[0043] Specific implementation mode one: combine figure 2 and image 3 Describe this specific embodiment, a method for measuring the waveform size of the three-lobe wave outer raceway of a bearing in this specific embodiment, the method is realized by the following steps,

[0044] Step 1. Selection of CMM:

[0045] The reference600 high-precision three-coordinate measuring instrument is selected for measurement, and according to the measurement requirements of the three-lobe outer raceway, the measurement of the waveform size of the three-lobe outer raceway bearing is realized through programming;

[0046] Step 2. Selection of measuring probes:

[0047] Use reference probes and non-reference probes for measurement. Non-reference probes include vertical probes and disc probes. The vertical probes are used to measure the three-lobe wave outer circle reference: end face, outer diameter, end face narrow convex Platform measurement, the disc probe is used to measure the three-l...

specific Embodiment approach 2

[0063] Embodiment 2: The maximum allowable error of the reference600 high-precision three-coordinate measuring instrument in step 1 of this embodiment is E=(1.0+L / 350) μm. Such setting ensures the measurement accuracy of the waveform size of the three-lobed outer raceway of the bearing. Other compositions and connections are the same as in the first embodiment.

[0064] The reference600 high-precision three-coordinate measuring instrument of this embodiment is the reference600 high-precision three-coordinate measuring instrument of the German company Leitz.

specific Embodiment approach 3

[0065] Embodiment 3: The reference probe in step 2 of this embodiment is a φ5mm probe. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com