Lens detection device

A detection device and lens technology, which is applied to measurement devices, mechanical measurement devices, and mechanical devices, etc., can solve the problems of low efficiency, high cost, time-consuming and labor-intensive, etc., to avoid scratches, convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following specific examples illustrate the present invention in further detail.

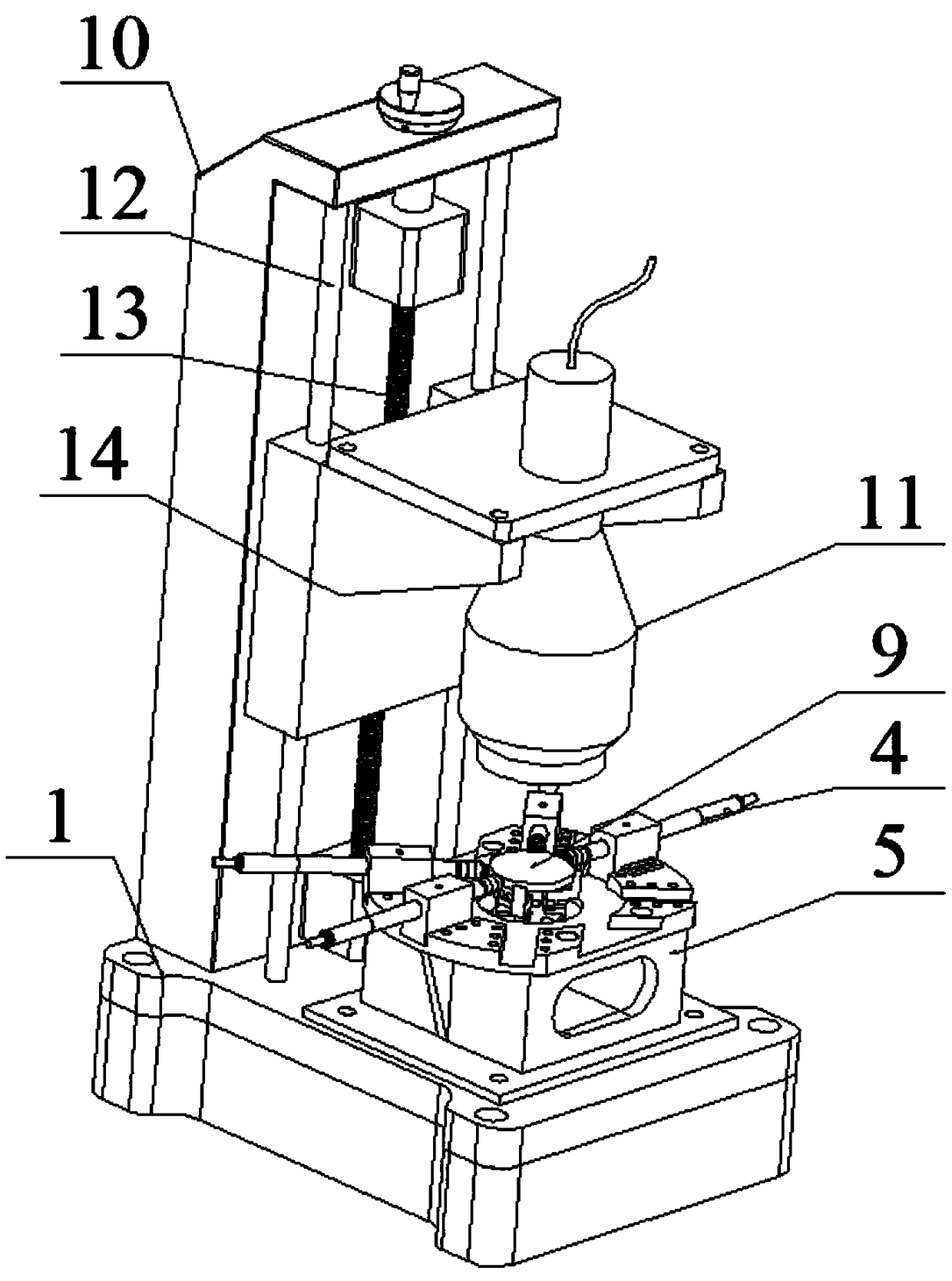

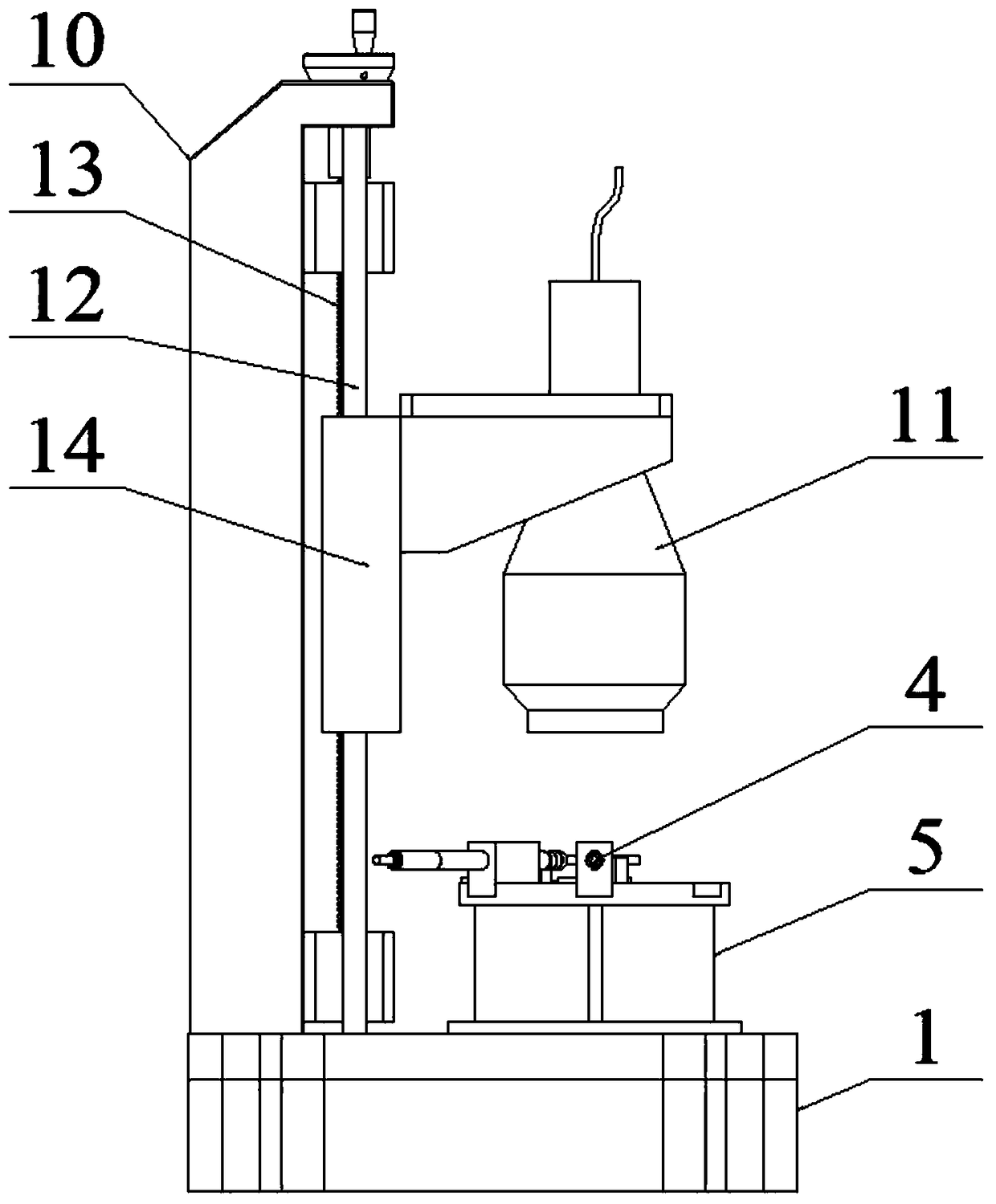

[0030] Such as Figure 1-7 As shown, a lens detection device provided by the present invention is mainly used to detect the center thickness and outer diameter error of the lens, including a first detection device for detecting the lens center thickness and a second detection device for detecting the lens outer diameter error device.

[0031] Such as Figure 1~2 As shown, the first detection device and the second detection device of this embodiment are all fixed on the base 1, wherein the first detection device is located directly above the carrier for carrying the lens 9, and the second detection device is located around the carrier . The first detection device includes a fixed bracket 10 fixed on the base 1, on which a guide rod 12 and a screw 13 arranged vertically are installed, and the screw 13 is driven by a motor on the fixed bracket 10 to rotate around its own axis. The gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com