Bypass system comprehensive control method for improving the adjusting capacity of heat supply unit

A technology of heating unit and bypass system, which is applied in the direction of heating system, steam central heating system, heating method, etc., can solve the problem that the comprehensive control of bypass system has not been studied in a targeted manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

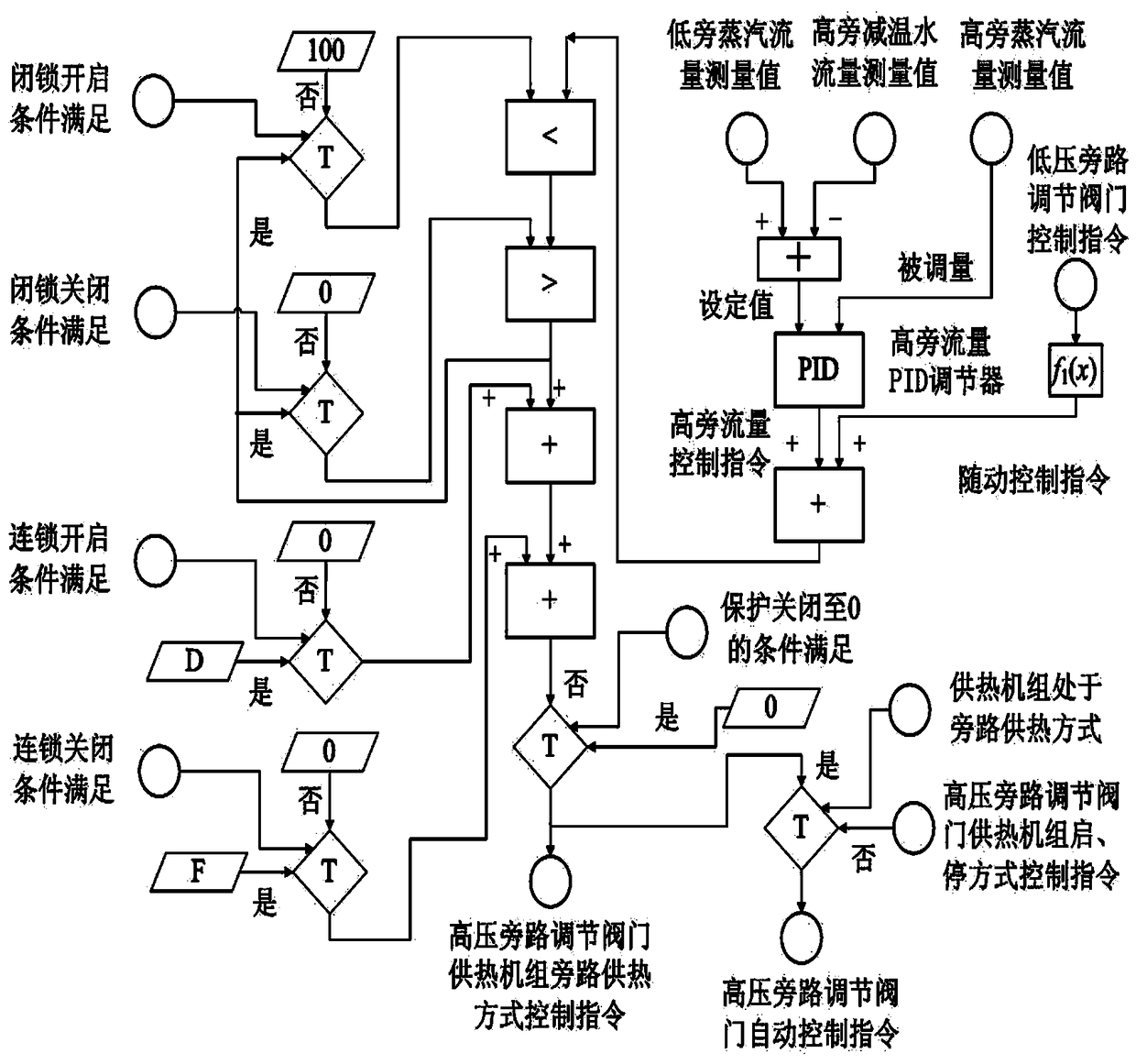

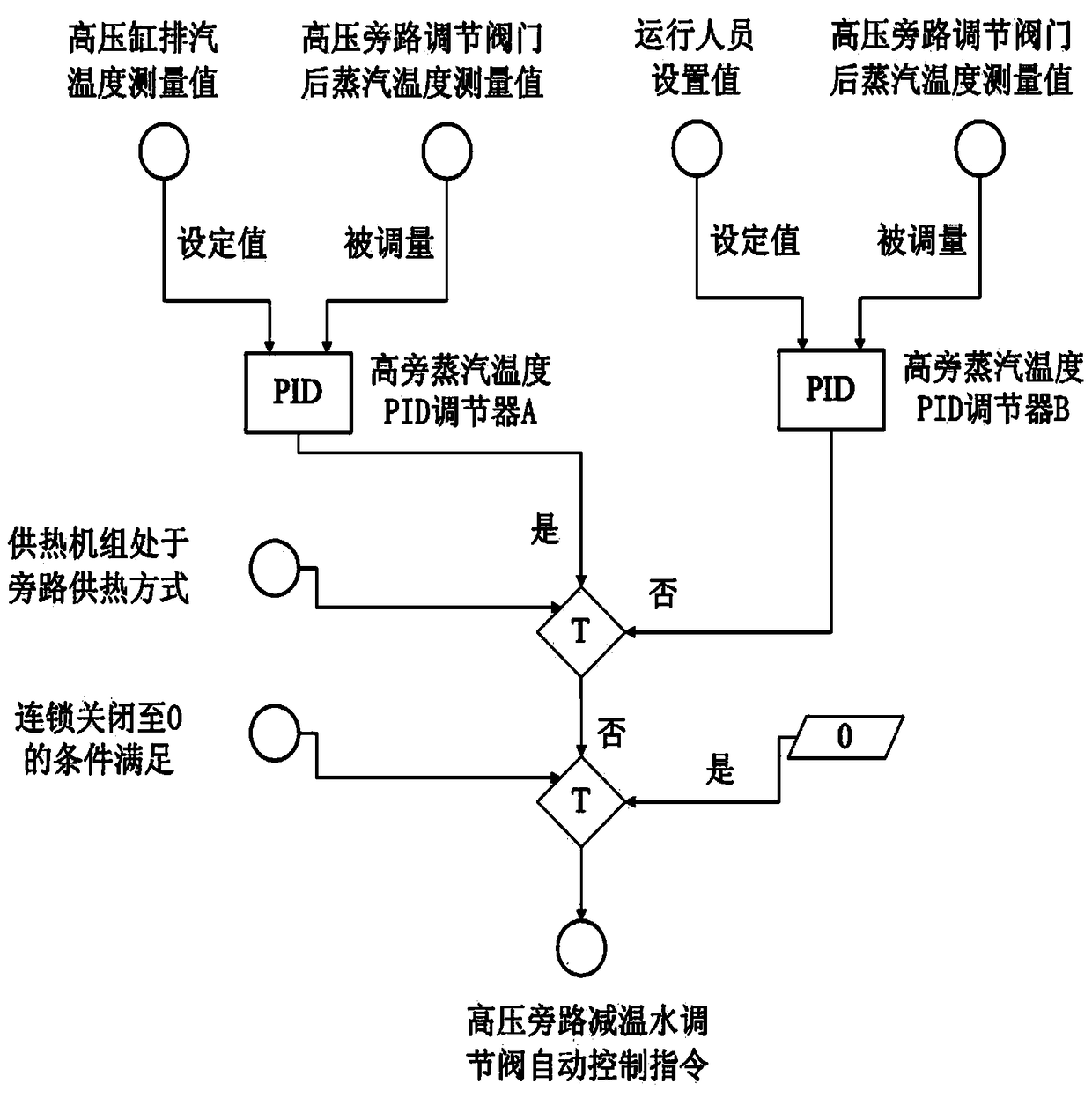

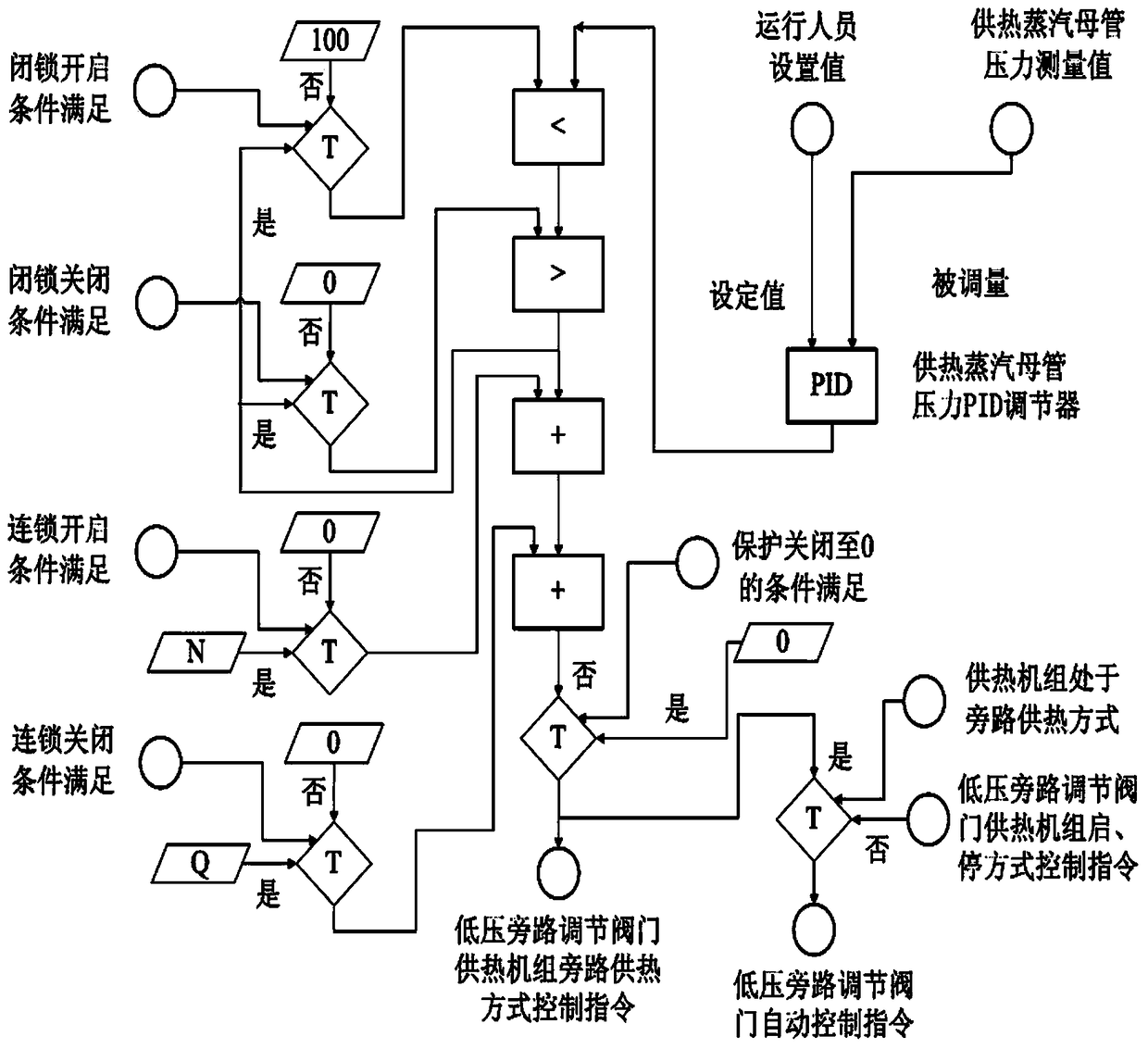

[0077] The invention is a comprehensive control method of a bypass system for improving the adjustment ability of a heating unit, comprising the following steps:

[0078] Step 1: Improve the adjustment capacity of the heating unit by comprehensively controlling the bypass system of the heating unit. The bypass system includes a high-pressure bypass system and a low-pressure bypass system. The control valves of the high-pressure bypass system include high-pressure bypass regulating valves , High-pressure bypass desuperheating water regulating valve and high-pressure bypass regulating valve front shut-off valve, low-pressure bypass system control valves include low-pressure bypass regulating valve, low-pressure bypass desuperheating water regulating valve, low-pressure bypass to condenser shut-off The valve and the low-pressure bypass to the shut-off valve of the heating network heater; during the heating period, the bypass system is not only used to control the temperature and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com