Inner-locking type tube fitting of connecting rod structure device

A connecting rod structure, internal locking technology, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve problems such as large leakage hazards, slow installation process, damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

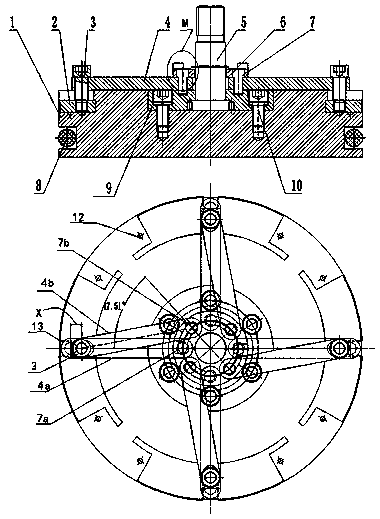

[0017] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0018] see Figure 5 , as a reference, shows the cross-sectional structure of the existing internal locking pipe fittings. The existing locking hole for the locking pin has a large leakage hidden danger. As a comparison, the locking structure of the present invention can be clearly distinguished different place.

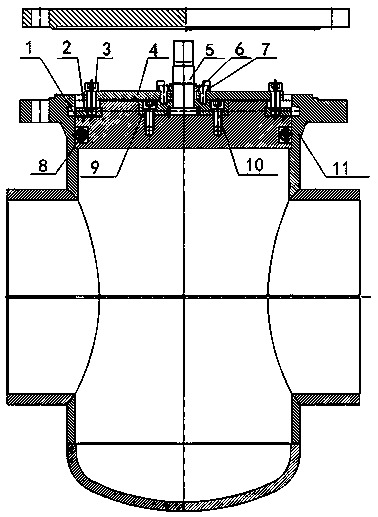

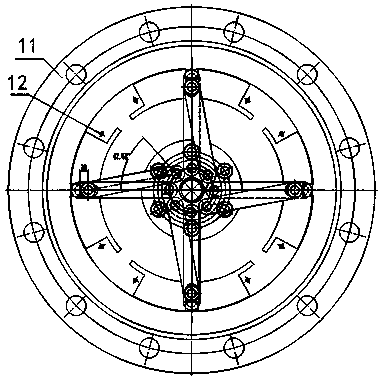

[0019] see Figure 1-2 , showing the structural schematic diagram of the internal lock pipe fitting of the connecting rod structure device according to the embodiment of the present invention, including a plug 1, a lock ring 2, a fastening screw 3, a connecting rod 4, a handle 5, a dial 6, a pin 7, an O-shaped Ring 8, screw base 9, fixing screw 10, four-way pipe fitting 11 and positioning pin 12, an annular groove 11a is provided in the four-way pipe fitting 11 flange, plugging 1 seals the four-way pipe fitting 11 flange hole, and plug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotatable angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com