Treatment device for kitchen waste water and discharged waste

A technology for processing equipment and kitchen waste, applied in water supply installations, indoor sanitary plumbing installations, buildings, etc., can solve the problems of heavy workload, increased waste water treatment cost, and large amount of waste water, so as to reduce the burden of transportation and make it easy to handle and degradation, the effect of huge environmental benefits

Pending Publication Date: 2019-03-08

南京博思闻科技有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional food waste treatment equipment on the market is installed at the lower mouth of the vegetable sink. The food waste generated in the kitchen enters the food waste treatment equipment through the vegetable sink, and then is crushed and discharged into the sewer. The disadvantages of this equipment are obvious: One is that the function is single, and it can only passively process the kitchen waste in the vegetable sink; the other is that the waste residue is discharged into the sewer, which is easy to block the sewer, increasing the burden on the municipal sewer and increasing the cost of wastewater treatment; the third is that the waste residue is easily fermented in the municipal sewer , produce various flammable, toxic and harmful gases, leaving potential safety hazards; fourth, a large amount of waste residue enters the water body, forming eutrophication of the water body, which seriously affects the ecology; in addition, for large cooking units such as canteens and restaurants, the number of times of washing pots every day is too high , There is a lot of waste water, and many pots are large in size and deep in depth. The cleaning of the pot washing water is manually scooped out, which takes a long time and a lot of work.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

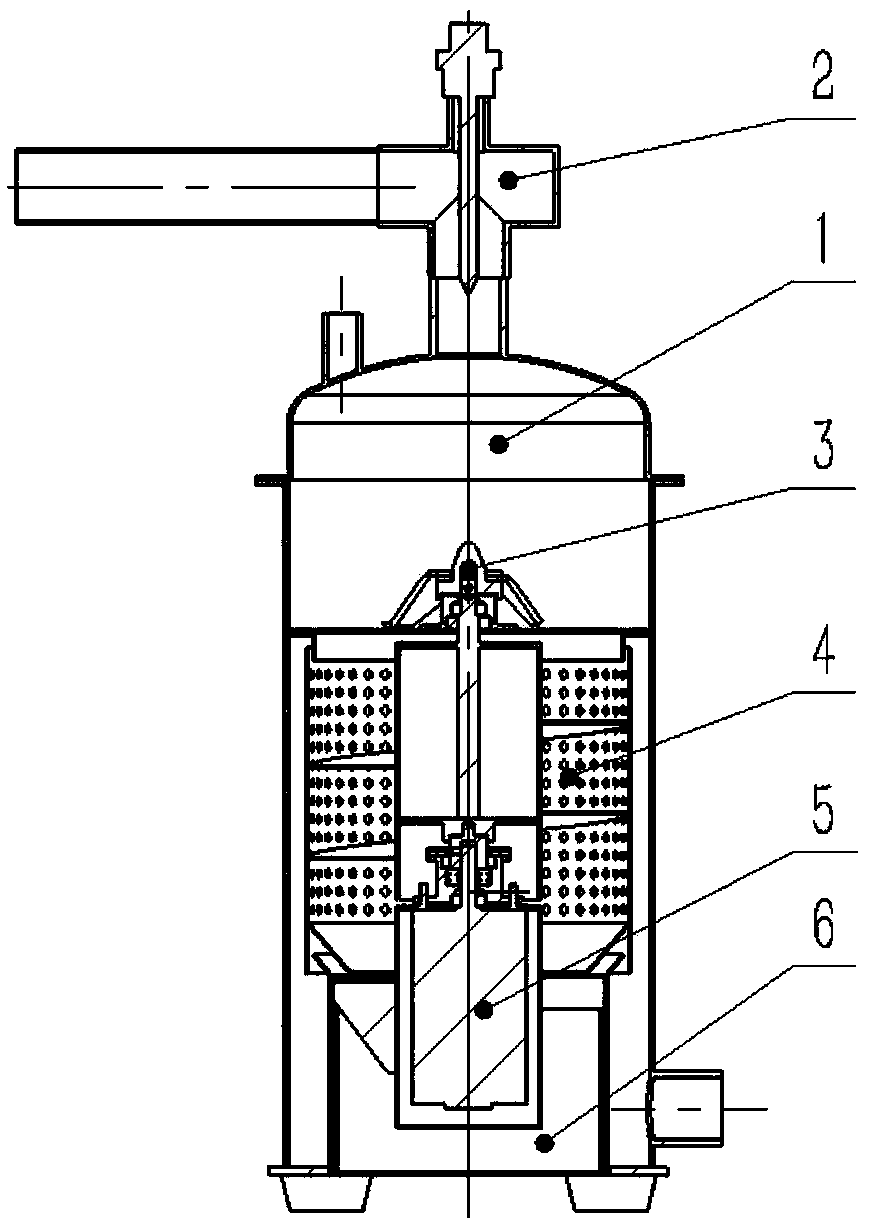

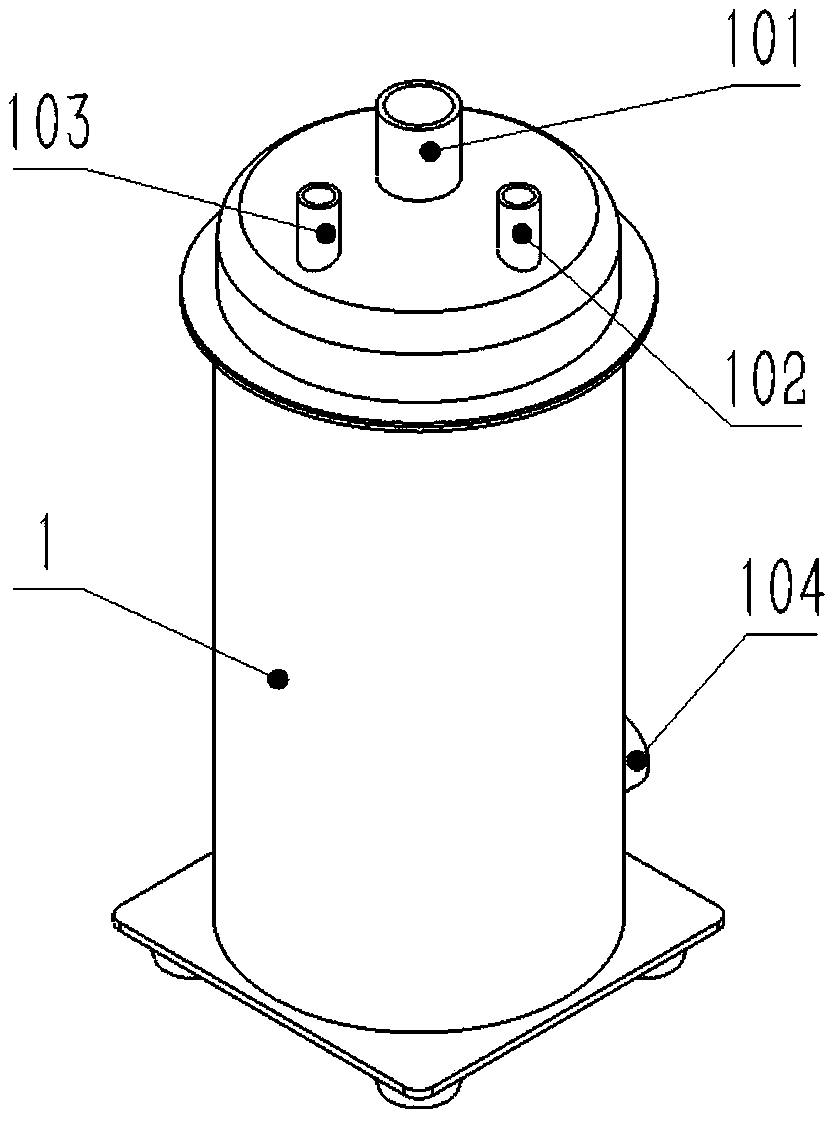

The invention belongs to the field of kitchen equipment and discloses kitchen waste water pump drainage and kitchen waste treatment equipment, which comprises an outer shell component, a pumping device, a smashing device, a separating device, a motor component and a residue barrel. The invention provides the kitchen equipment which can pump waste water in cookers and smash and separate residues. The equipment can clean water accumulated in a pot through a pumping function, send waste water containing solid wastes including vegetable leaves, broken bones and the like to the equipment, and smashthe solid wastes, the smashed residues enter the separating device together with the waste water, water is thrown out and discharged out of the equipment under the action of a centrifugal force generated through high speed rotation, residues enter the residue barrel to be collected and treated, further, the equipment allows running water to enter to clean automatically, and after being introducedinto the equipment, high temperature steam can sterilize the equipment at a high temperature, so as to keep the equipment clean and sanitary all the time.

Description

technical field The invention belongs to the field of kitchen waste treatment, in particular to a kitchen waste water pumping and discharging kitchen waste treatment equipment. Background technique The traditional food waste treatment equipment on the market is installed at the lower mouth of the vegetable sink. The food waste generated in the kitchen enters the food waste treatment equipment through the vegetable sink, and then is crushed and discharged into the sewer. The disadvantages of this equipment are obvious: One is that the function is single, and it can only passively process the kitchen waste in the vegetable sink; the other is that the waste residue is discharged into the sewer, which is easy to block the sewer, increasing the burden on the municipal sewer and increasing the cost of wastewater treatment; the third is that the waste residue is easily fermented in the municipal sewer , produce all kinds of flammable, toxic and harmful gases, leaving hidden safety ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E03C1/266

CPCE03C1/2665

Inventor 杨小兵武新平许海祥杨志川安竹云朱雪珍王云

Owner 南京博思闻科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com