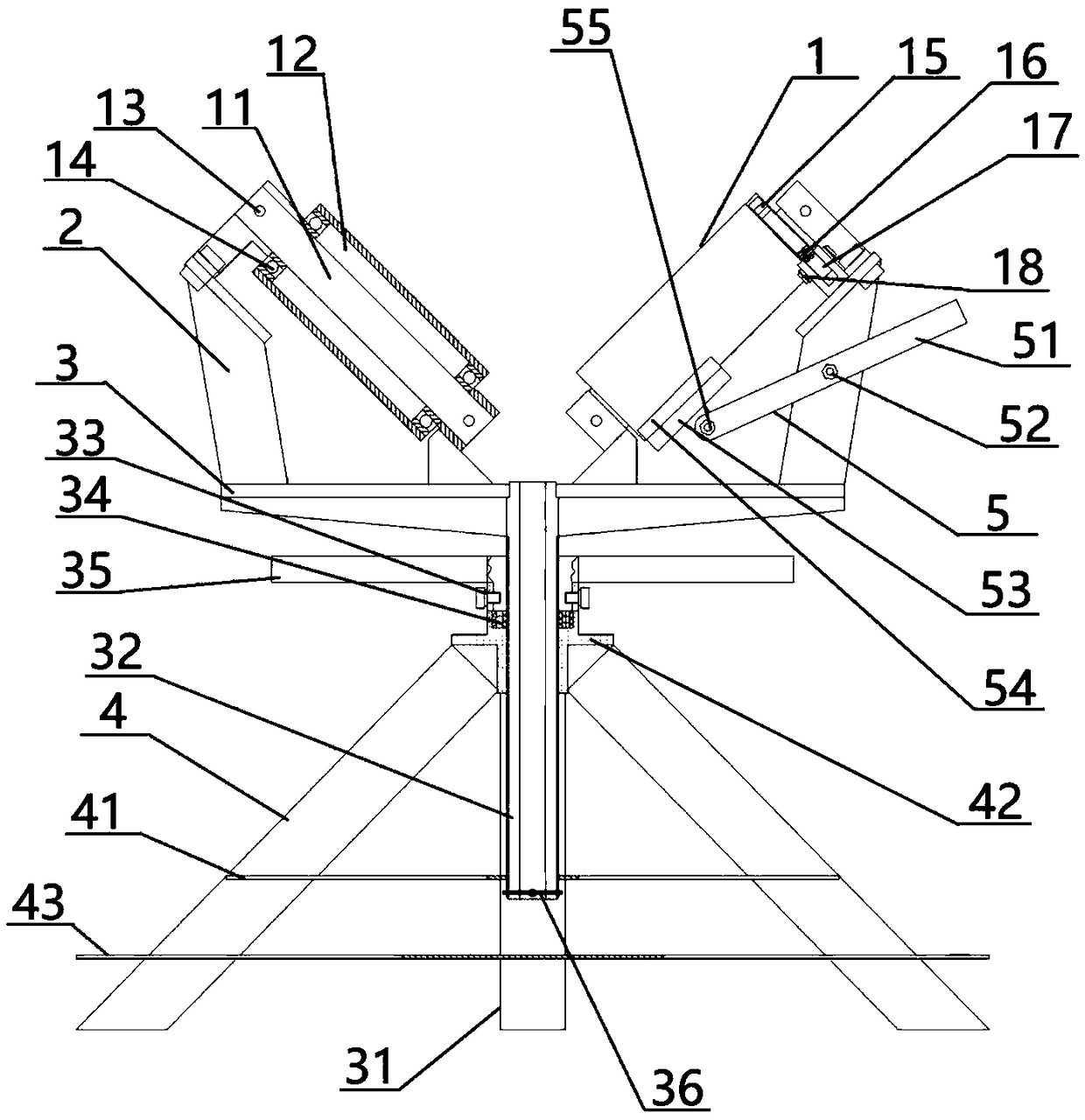

Telegraph pole conveying device

A technology for conveying devices and electric poles, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of injury to lifters, wear and damage on the surface of electric poles, etc., so as to improve lifting efficiency and reduce labor intensity , the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

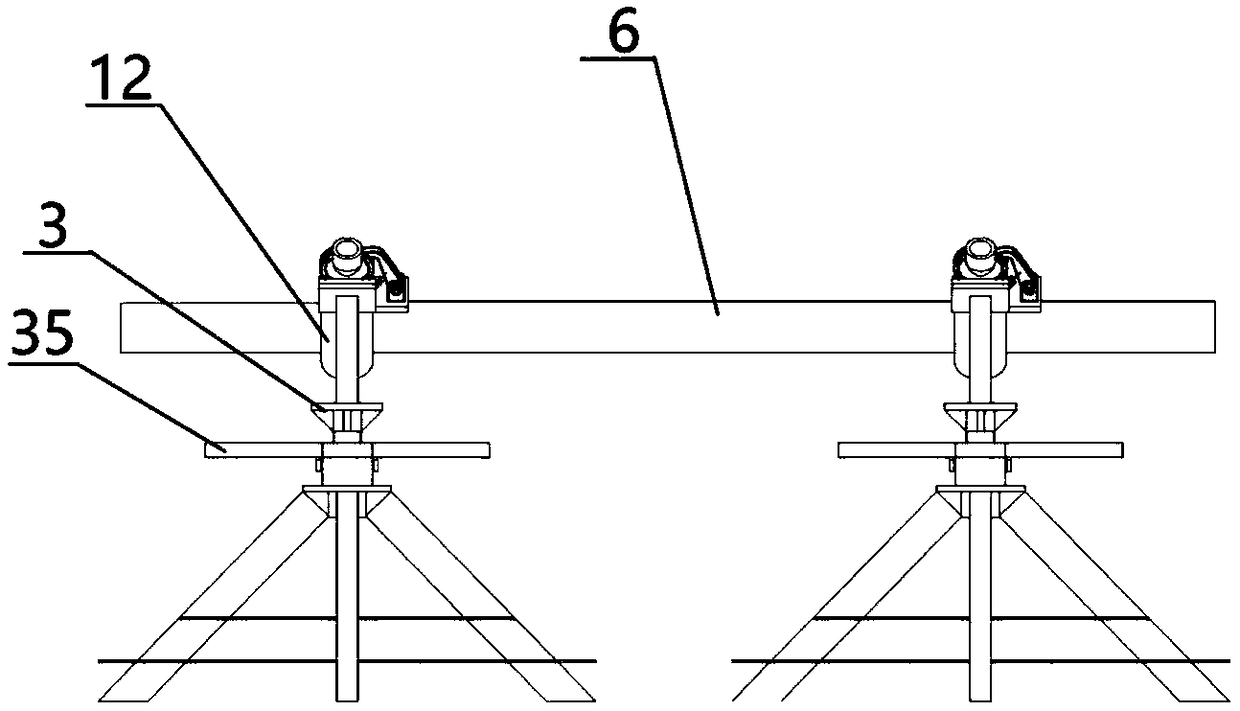

[0022] Such as figure 2 As shown, in the specific use process, when the electric pole 6 needs to be transported over a long distance, the conveying direction is selected, and the first electric pole conveying device ( figure 2 Select the right side as the first pole conveying device, assuming that the pole 6 is conveyed from the right to the left), lift one end of the pole 6 with a wire rope, put it on the pole conveying device, and then push the pole 6 to make the roller 12 Rotate, push the pole 6 up, according to the movement of the center of gravity of the pole 6 on the first pole conveying device, set up the second pole conveying device in time before the center of gravity moves out of the first pole conveying device, Place it in a suitable position. Since the center of gravity of the pole 6 is on the right side of the first pole conveying device at this time, the left side of the pole 6 is tilted up, and the second pole conveying device is directly placed under the left...

Embodiment 2

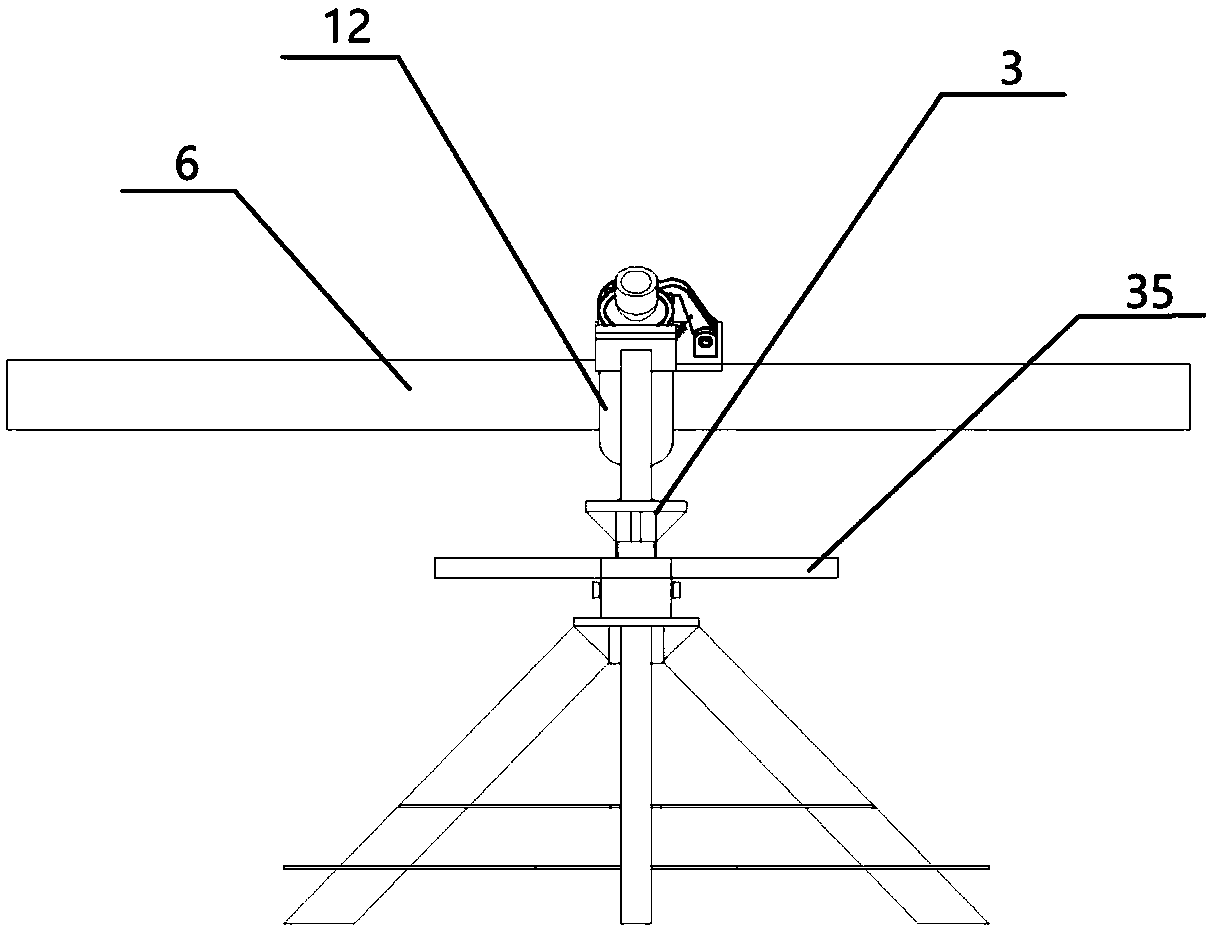

[0025] Such as image 3 As mentioned above, in some sites, it is necessary to adjust the direction of the electric pole 6. At this time, the rotating handle 35 can be turned to bring the lifting screw 32 to the lowest position, and one end of the electric pole 6 can be lifted with a wire rope, mounted on the electric pole conveying device, and pushed Electric pole 6, so that the electric pole 6 can basically be suspended in the air, turn the electric pole 6, and the electric pole 6 can rotate under the cooperation of the turntable 3, and when it is rotated to a suitable angle, the electric pole 6 can be pushed down from the electric pole conveying device, and the electric pole 6 is completed. Adjust the demand for the direction of pole 6. The 180° direction adjustment of the electric pole 6 can be completed by using the electric pole conveying device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com