N, N'-di-sec-butyl-p-phenylenediamine simulation teaching factory

A technology of di-sec-butyl-p-phenylenediamine and simulation teaching, which is applied in the fields of chemical technology and equipment and education, can solve the problems of inability to learn the realism of chemical equipment, no chemical production equipment, and limited production equipment, so as to cultivate job skills. and professionalism, enhancing teamwork and problem-solving efforts, and improving cognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

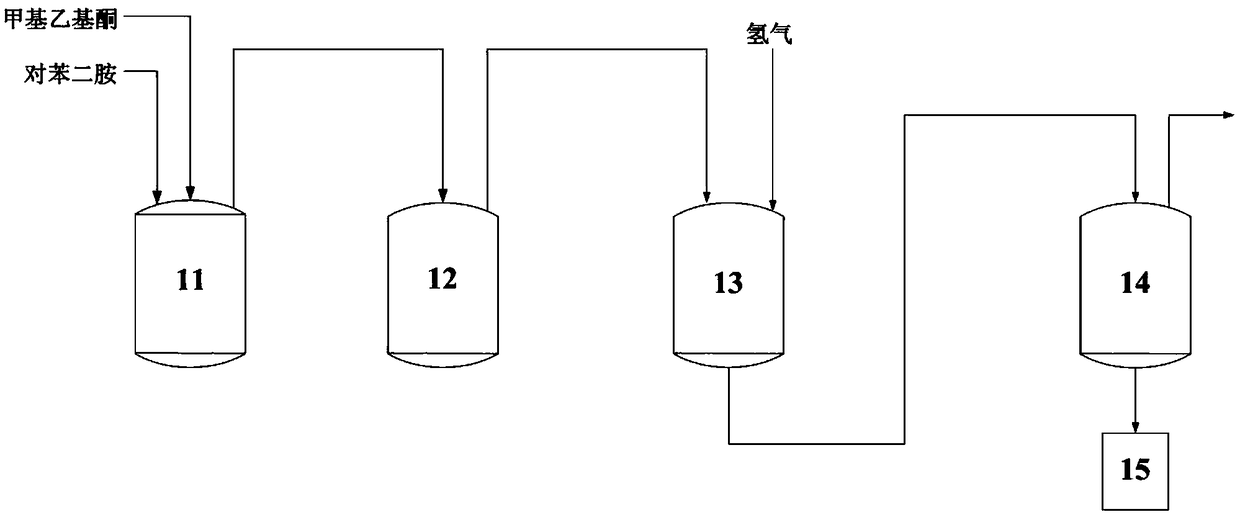

[0017] Embodiment: The embodiment of the present invention is based on the transformation of a 180t / a p-phenylenediamine reductive alkylation production device. The geometric dimensions of the equipment are consistent with the actual production device equipment. The pipes, valves and measuring elements are all in actual proportions. The display instrument is the same as the actual device.

[0018] Qualified p-phenylenediamine and methyl ethyl ketone are mixed in the batching tank 11; after confirming that they are fully dissolved, the solution is sent from the batching tank 11 to the middle tank 12, the solid matter is separated, and the supernatant is sent to the reduction tank 13; hydrogen and catalyst, the heat of reaction is provided by steam, and after the reaction is completed, the reaction liquid is sent to rectification still 14; by steam heating, N,N'-di-sec-butyl-p-phenylenediamine is separated from impurities in rectification still 14; The N,N'-di-sec-butyl-p-phenyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com