Sidewalk guard rail with drip and construction method of sidewalk guard rail

A technology for sidewalks and railings, applied to bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of asymmetric bridge structure cross-section, unsatisfactory drainage effect, general landscape effect, etc., to achieve convenient design and proofreading, prevent The effect of rainwater accumulation and project risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

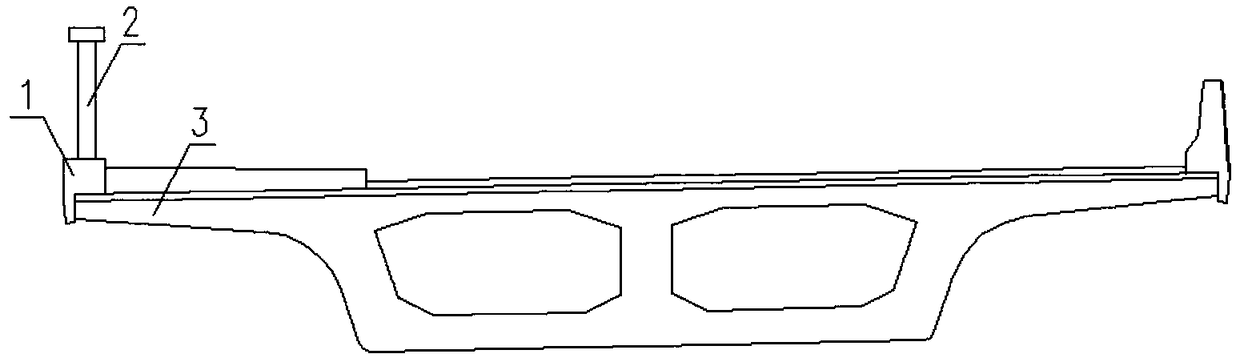

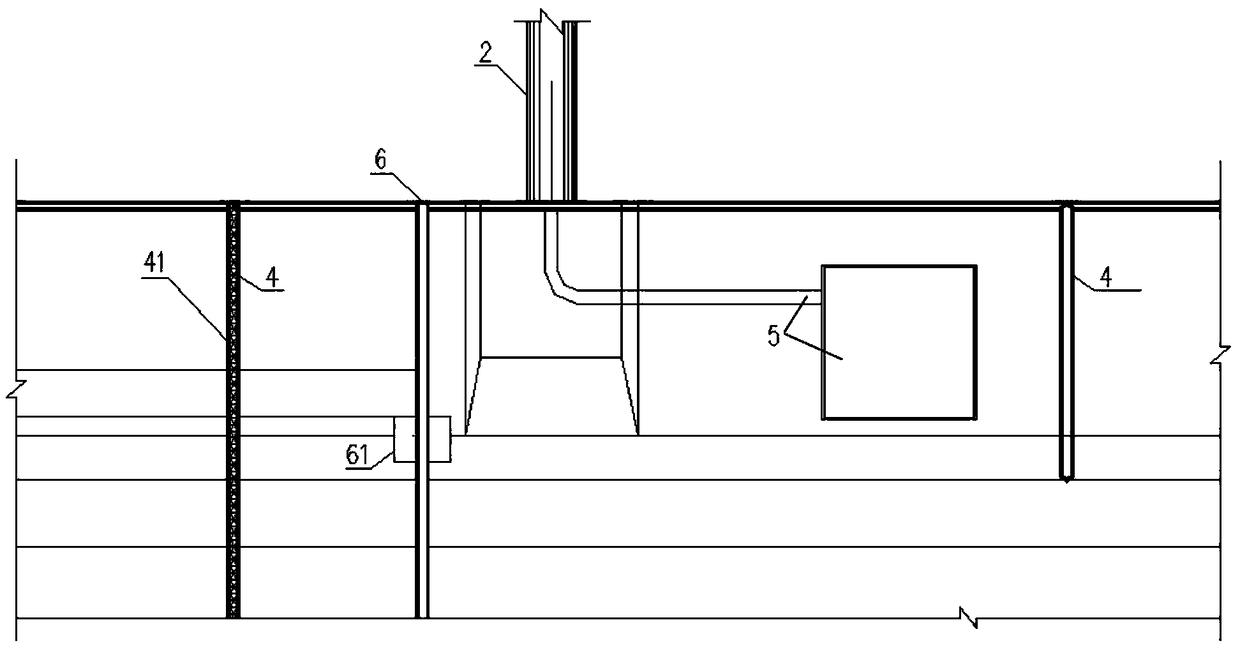

[0028] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 And attached figure 2 A sidewalk railing with dripping water provided by the present invention and its construction method are described in detail.

[0029] figure 1 It is a side view sectional view of an embodiment of a sidewalk railing with dripping water of the present invention; figure 2 It is a front view of an embodiment of a dripping sidewalk railing of the present invention. In this embodiment, the dripping sidewalk railing and its construction method mainly include a base 1, a column 2, a main beam 3, and a false joint 4 , filler 41, electrical equipment and pipeline 5, broken seam 6, polyethylene foam board 61.

[0030] The sidewalk railing includes a base 1 and several columns 2, the base 1 is arranged on the edge of the upper end surface of the main beam 3 along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com