A cloth conveying device for textile machinery

A cloth conveying and textile machinery technology, applied in the field of cloth conveying devices, can solve the problems of low cloth conveying efficiency, unfavorable assembly line production, and increase labor intensity of manual operation, so as to reduce labor intensity, reduce maintenance cost, and improve stability and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

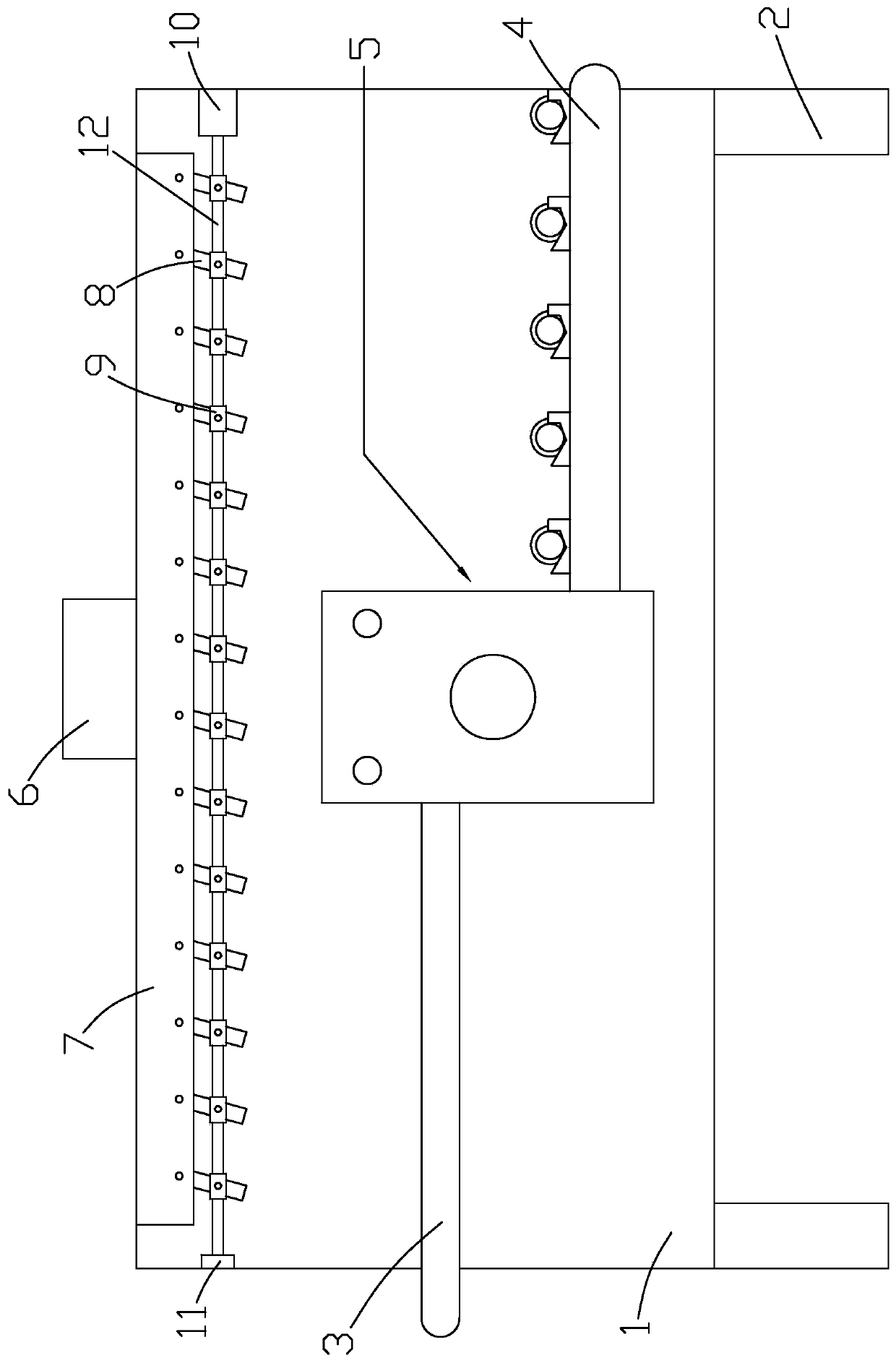

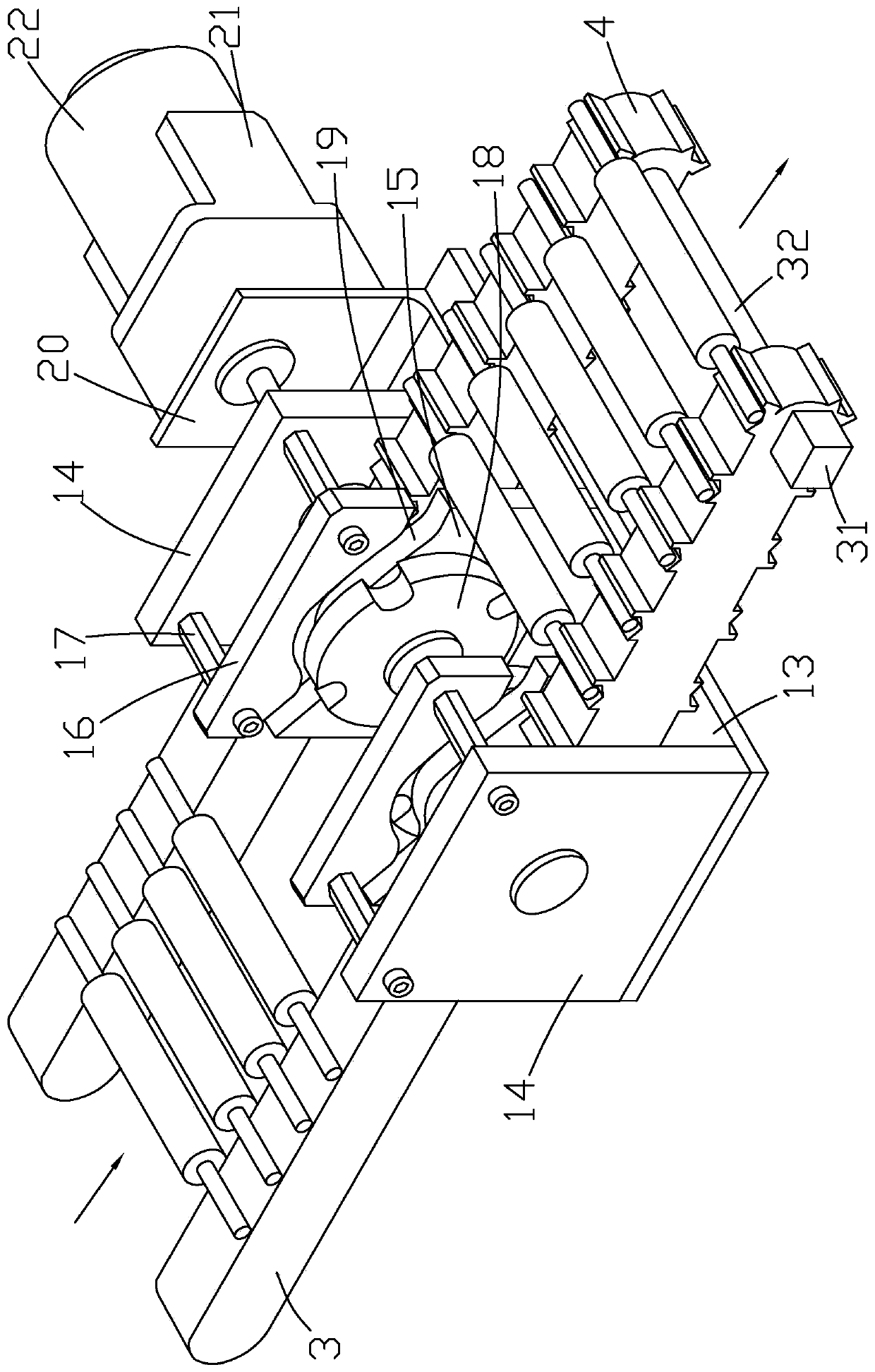

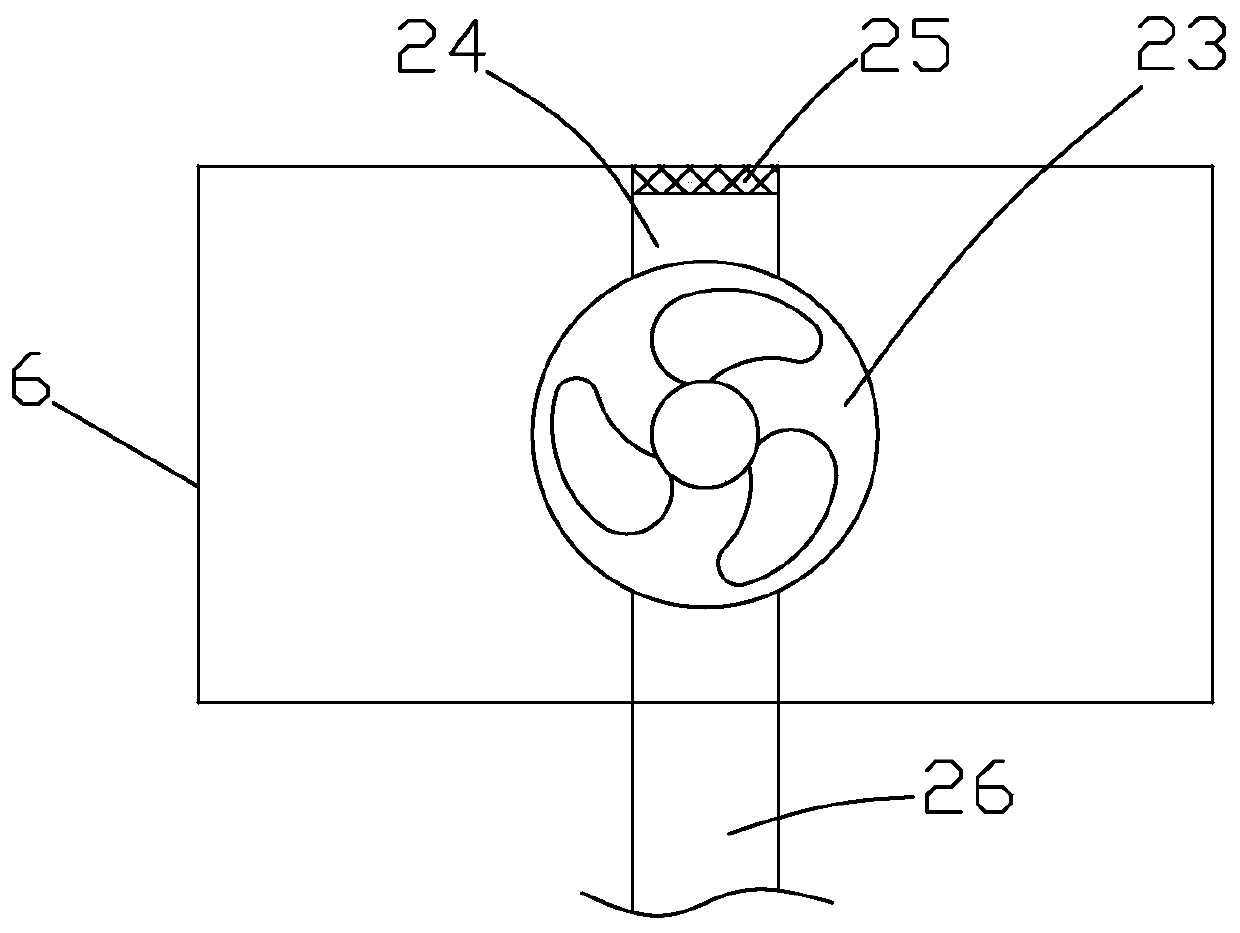

[0028] Such as Figure 1 to Figure 5 As shown, it is a cloth conveying device for textile machinery according to the present invention, which includes a box body 1, a support foot 2 is arranged on the bottom surface of the box body 1, an intermittent conveying mechanism 5 is arranged in the box body 1, and the intermittent conveying mechanism 5 Two feed belts 3 and two discharge belts 4 are respectively arranged on the left and right sides, and the distance between the two feed belts 3 is equal to the distance between the two discharge belts 4, which can ensure that the cloth conveying roller (Fig. Not marked in ) can be stably conveyed on the feed belt 3 and the discharge belt 4, preventing the feed belt 3 or discharge belt 4 from being stuck by the cloth conveying roller and affecting the normal operation of the entire production line, the discharge belt 4 Positioning strips 29 are evenly arranged on the outer surface of the locating strip 29, and a slot 30 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com