Verification-platform-based method for inputting and modeling of instrument-controlled finished product file

A modeling method and verification platform technology, applied in instruments, simulators, general control systems, etc., can solve problems such as labor-intensive, time-consuming, and large signal transmission, to eliminate manual intervention, speed up, and eliminate human interference. due to wrong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

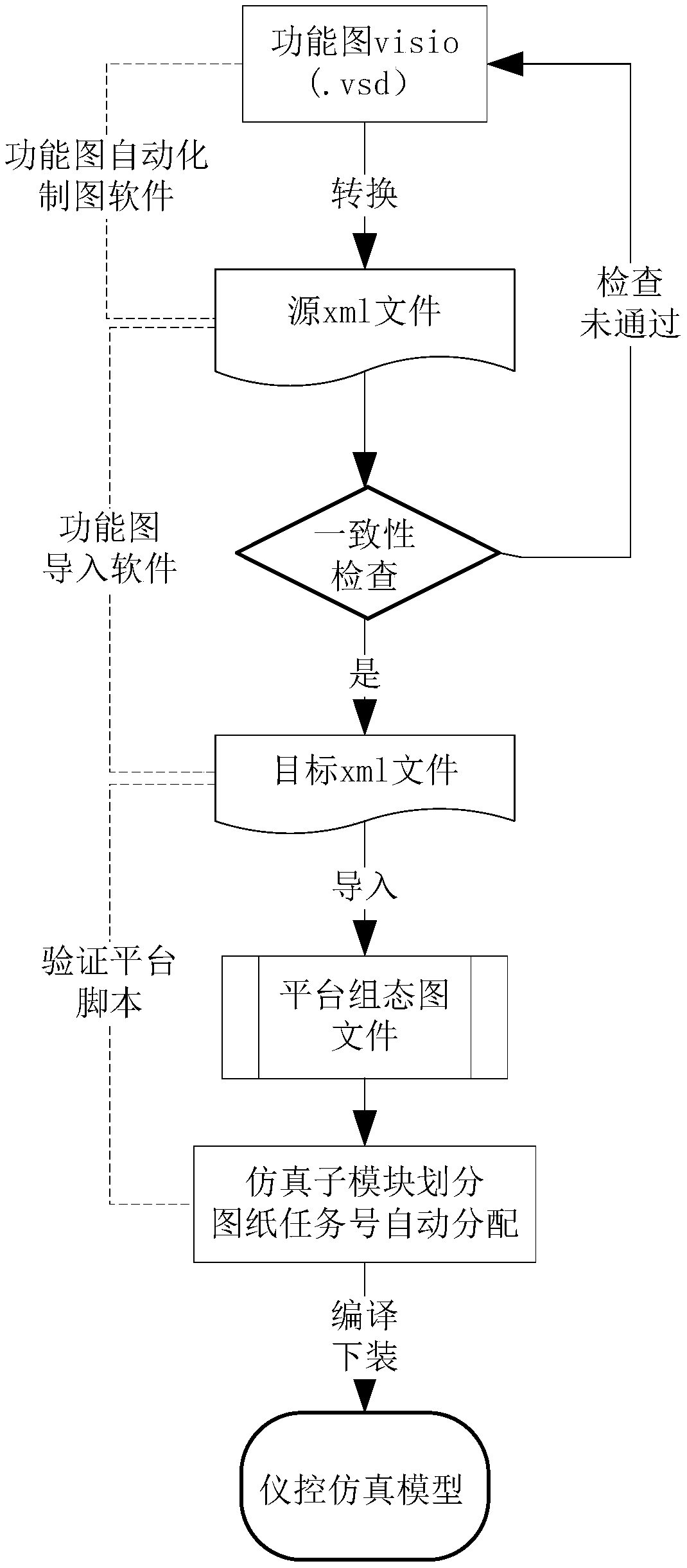

[0026] The flow of the exemplary verification platform-based instrument control product file import modeling method of the present invention is as follows: figure 1 shown, including the following steps.

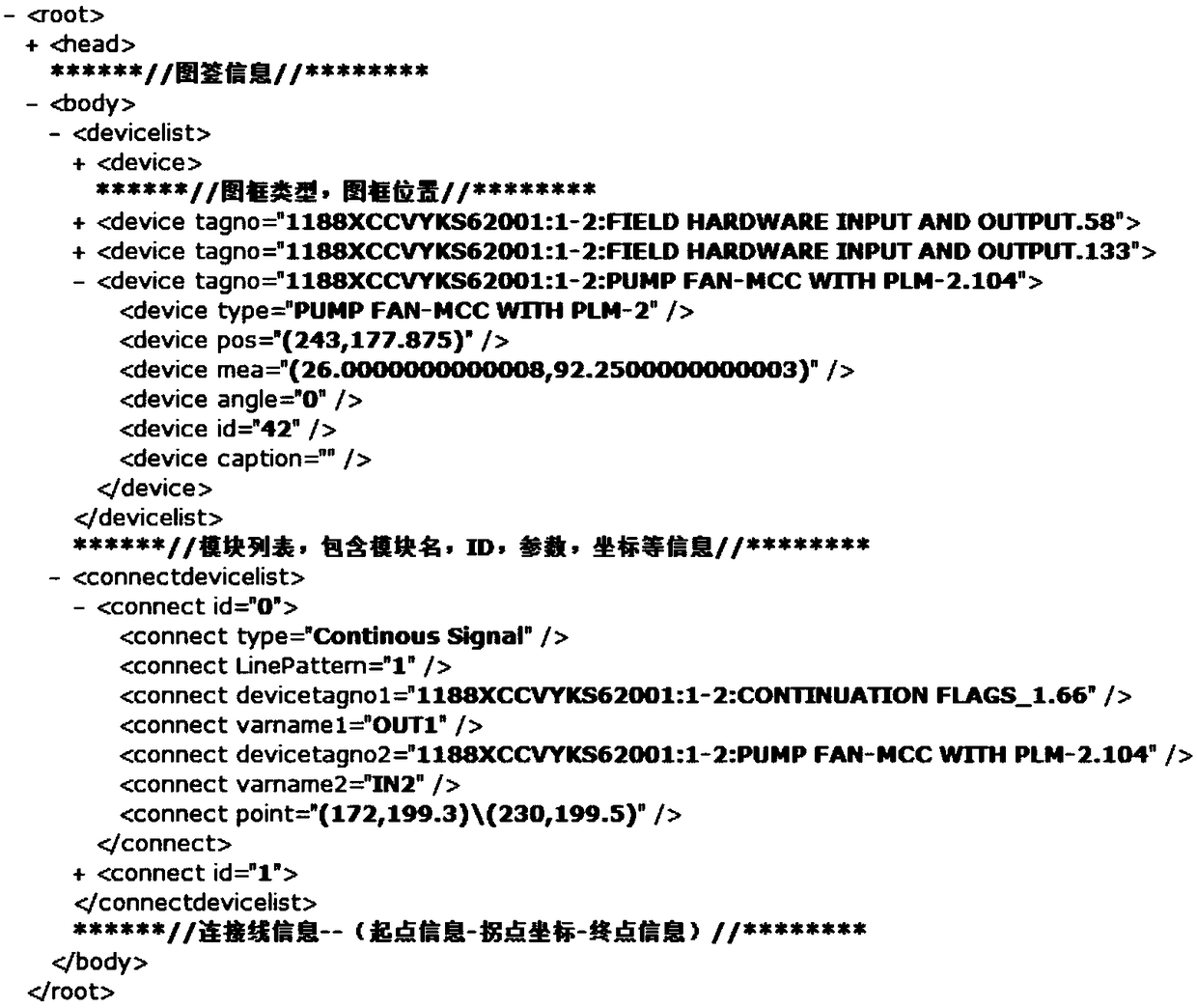

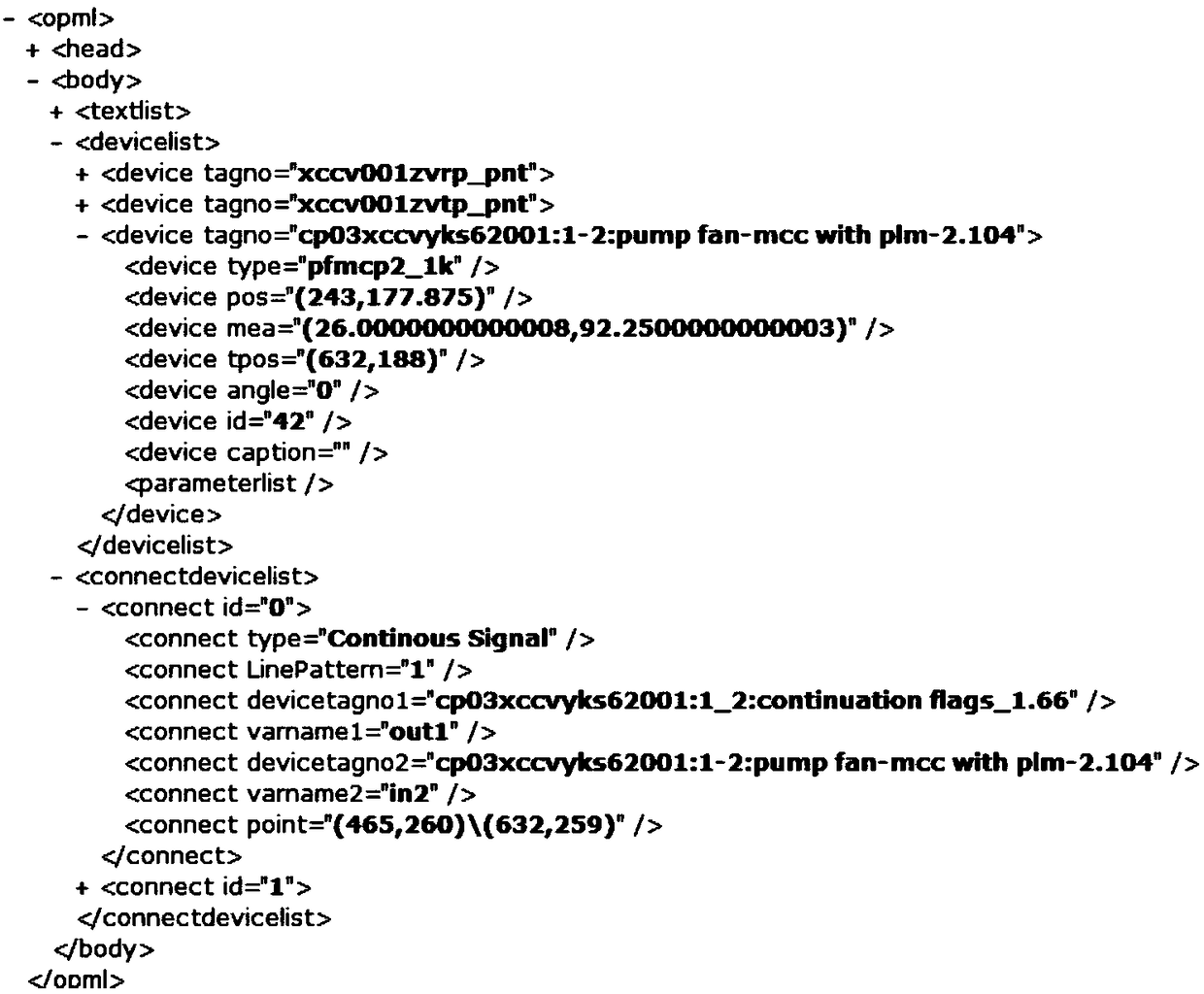

[0027] 1. Export the visio file of the functional diagram to a source xml file with a fixed format, and then perform format check and consistency check on the source xml file

[0028] DOM is the abbreviation of (Document Object Model), which is mainly used to establish a bridge between script and programming language, and is an application program interface for XML. DOM plans the xml data document into a document composed of multiple interconnected node levels. Each part in the document can be regarded as a derivative of Node, and the collection of nodes is regarded as a node tree (Tree).

[0029] Based on the DOM model, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com