GRC decorative line anti-cracking method

A decorative line, anti-cracking technology, applied in the direction of construction, building structure, etc., can solve problems such as cracks and water leakage and unsightly appearance, and achieve the effect of reducing unnecessary operations, saving costs, and repairing joints quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

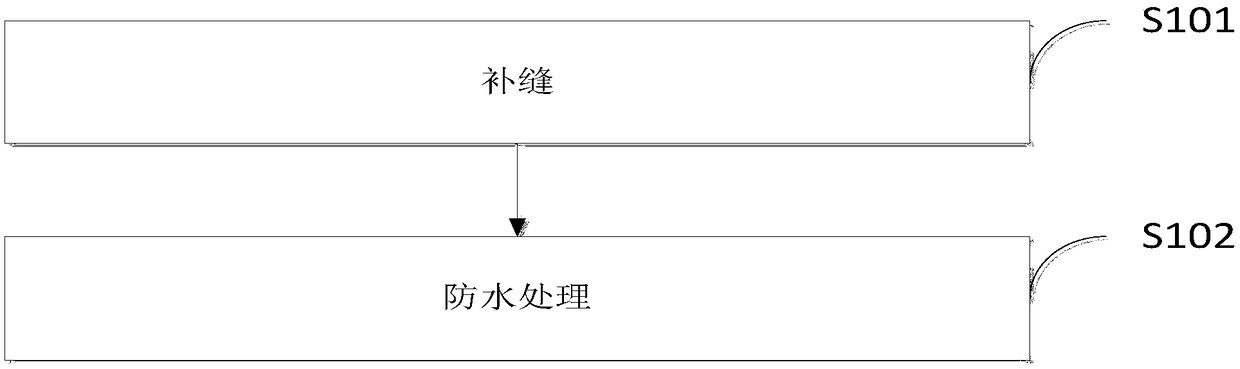

[0019] The anti-cracking method for GRC decorative lines comprises the following steps:

[0020] S101, mending seams;

[0021] A. Remove floating dust and other sundries from the seam filling area, and soak the seam filling area with water.

[0022] B. Stir the construction glue and cement in a ratio of 1:3 until there are no lumps and sticky, and place glass fiber cloth at the joints, and evenly insert the mixed construction glue into the joints for compaction, calendering, and components flat surface;

[0023] C. Actively maintain after repairing the seam;

[0024] S102, waterproof treatment;

[0025] After the seam repair is completed, waterproof treatment should be carried out at all seam positions with a width of 100mm, and waterproof rubber powder sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com