Full-automatic bagging machine of barrelled water

A barreled water and bagging machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of increasing the lifting time, affecting the bagging efficiency, shortening the length of the retractable support column, etc., to ensure the bagging efficiency , Increase sales and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

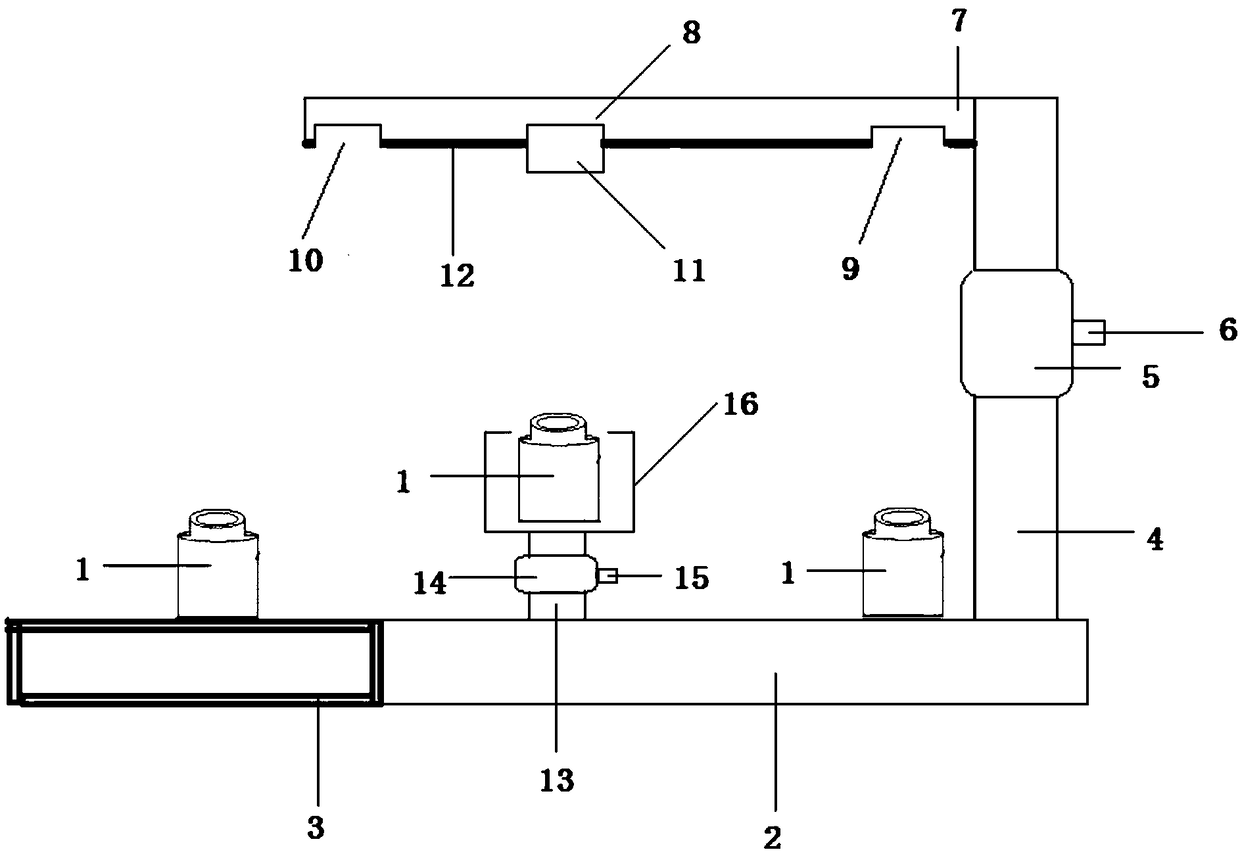

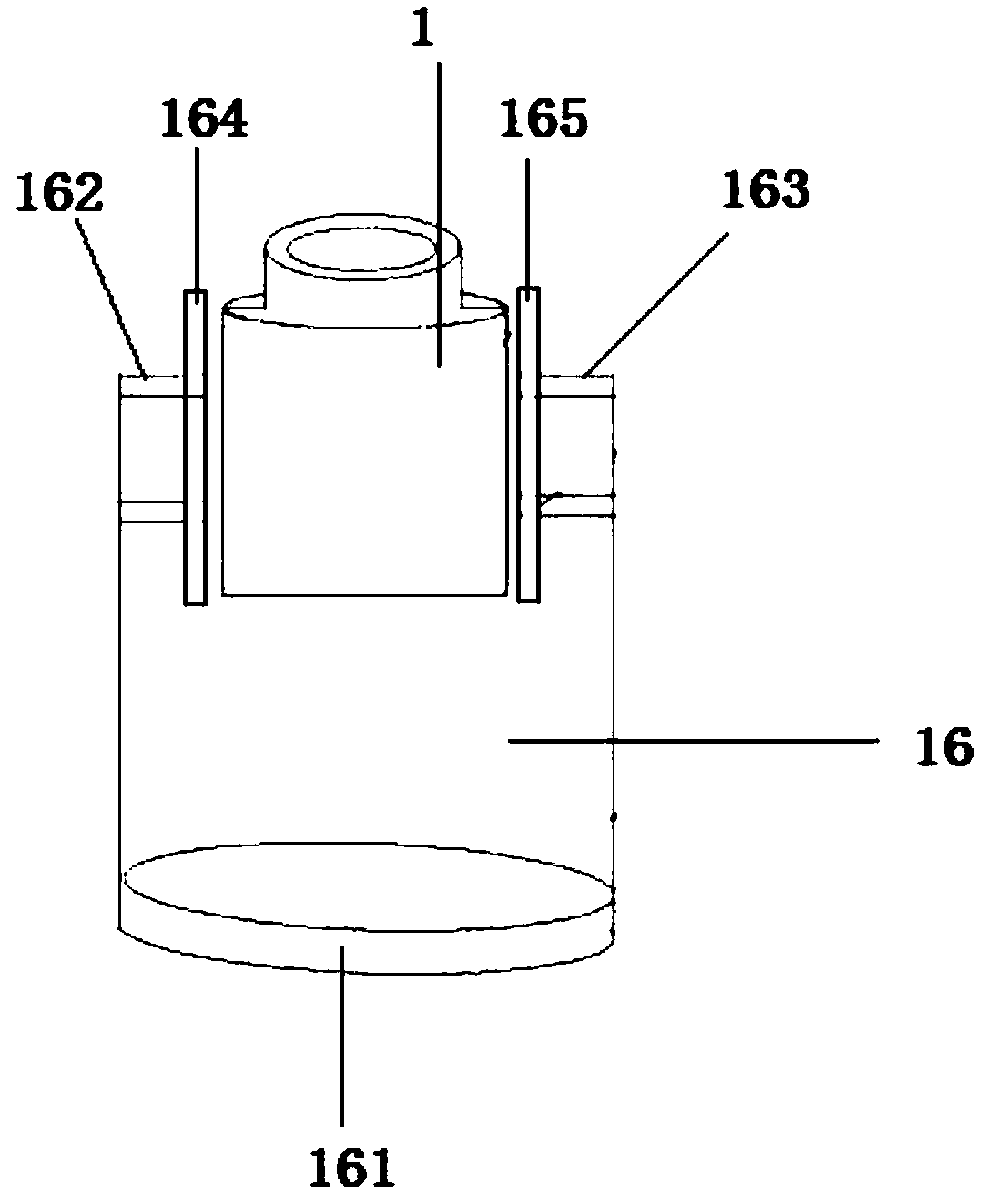

[0019] Such as figure 1 and figure 2 As shown, a fully automatic bagging machine for bottled water includes a working substrate 2, one side of the working substrate 2 is provided with a telescopic support column 4, and the middle part of the telescopic support column 4 is provided with a first telescopic device 5, the first telescopic device 5 is provided with a first telescopic adjuster 6, and the first telescopic device is stretched or contracted by manually adjusting the first telescopic adjuster, which can be adapted for bottled water of different specifications. For example, if the size of the bottled water is too large, it will take up too much space on the working base. It is necessary to increase the length of the telescopic support column through the first telescopic device. On the contrary, if the specification of the bottled water is too small, the space occupied on the working substrate is also too small. If the telescopic support column itself is too long, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com