Automatic cloth cutting workbench based on clothing processing

A technology of workbench and workbench frame, which is applied in the field of garment processing, and can solve problems such as easy threading, difficult handling of adhesion, and mutual adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

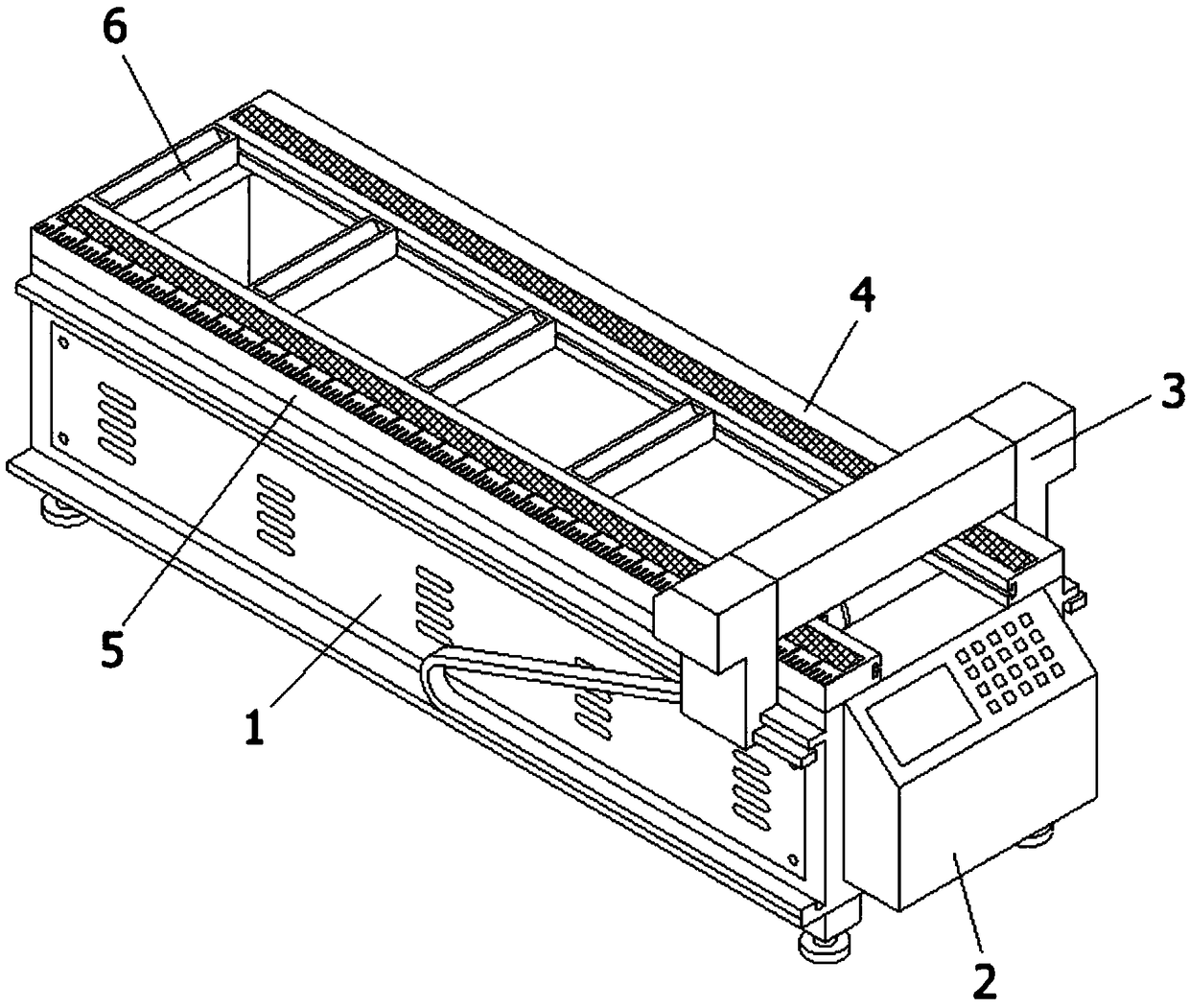

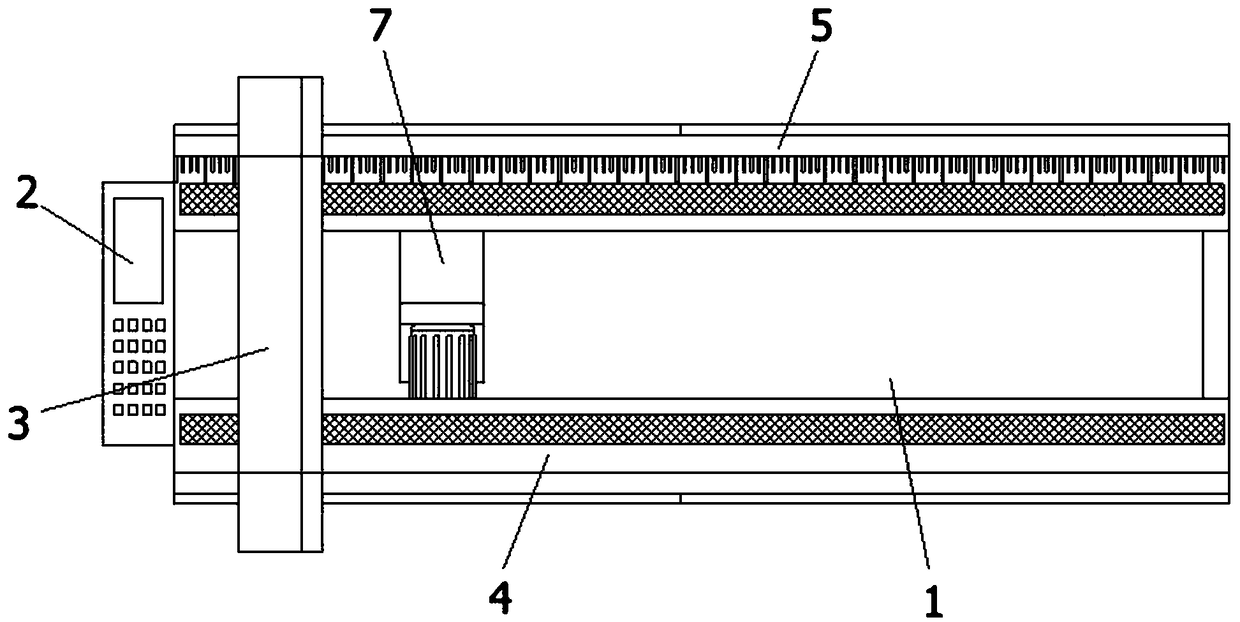

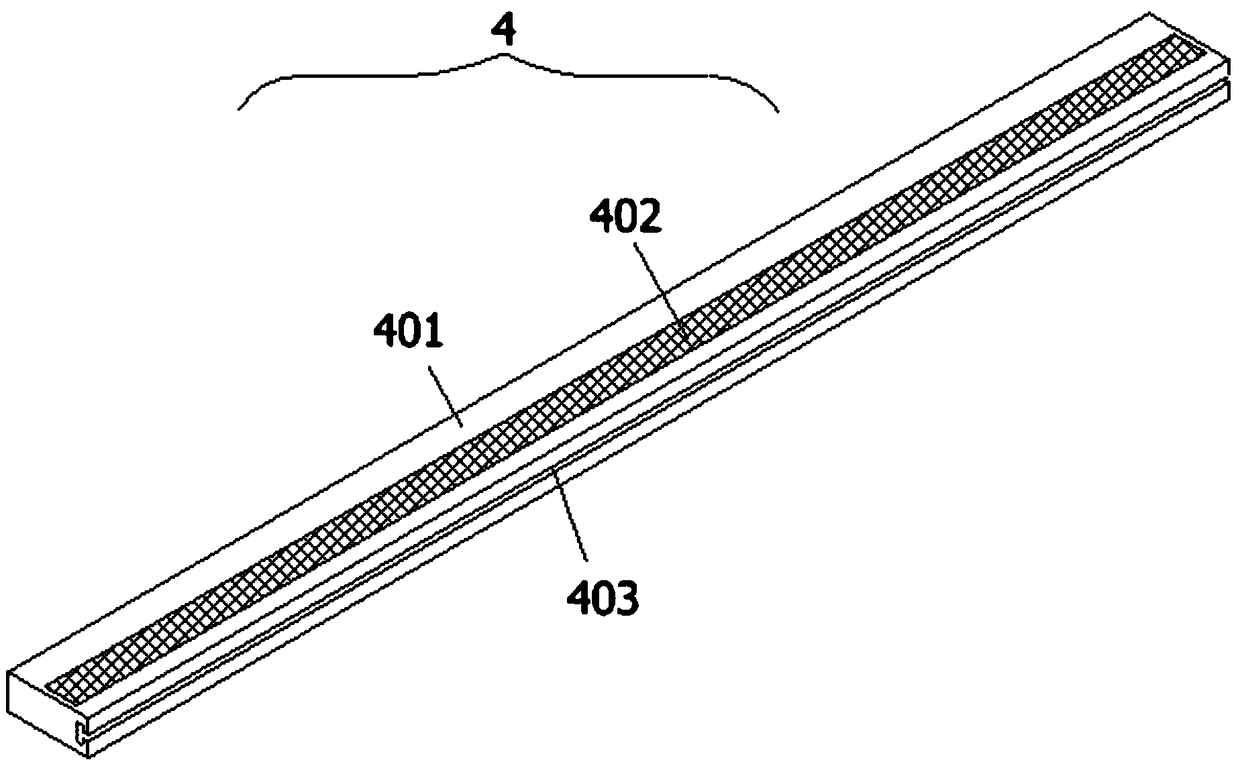

[0032] as attached figure 1 to attach Figure 10 Shown:

[0033] The invention provides an automatic cloth cutting workbench based on garment processing, including: a cloth cutting workbench body 1, a control box 2, a laser cloth cutting head 3, a right workbench 4, a rectangular plate A401, a mesh plate A402, and a T-shaped Chute A403, vacuum chamber A404, left workbench 5, rectangular plate B501, mesh plate B502, T-shaped chute B503, scale 504, vacuum chamber B505, anti-sticking device 6, rectangular block 601, T-shaped slider 602 , rubber sheet 603, micro fan 604, rectangular groove 605 and vacuum pump 7; a laser cutting head 3 is installed on the top of the cloth cutting table frame body 1 through a linear servo step control system, and the cloth cutting table frame body 1 The front end is equipped with a control box 2 electrically connected to the laser cloth cutting head 3 and the linear servo stepping control system; a left workbench 5 is fixedly connected to the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com