Rubber covering machine for printed products

A technology for printing and plastic wrapping machines, applied in packaging and other directions, can solve problems such as book cover pollution, and achieve the effect of saving costs, reducing equipment investment, and reducing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

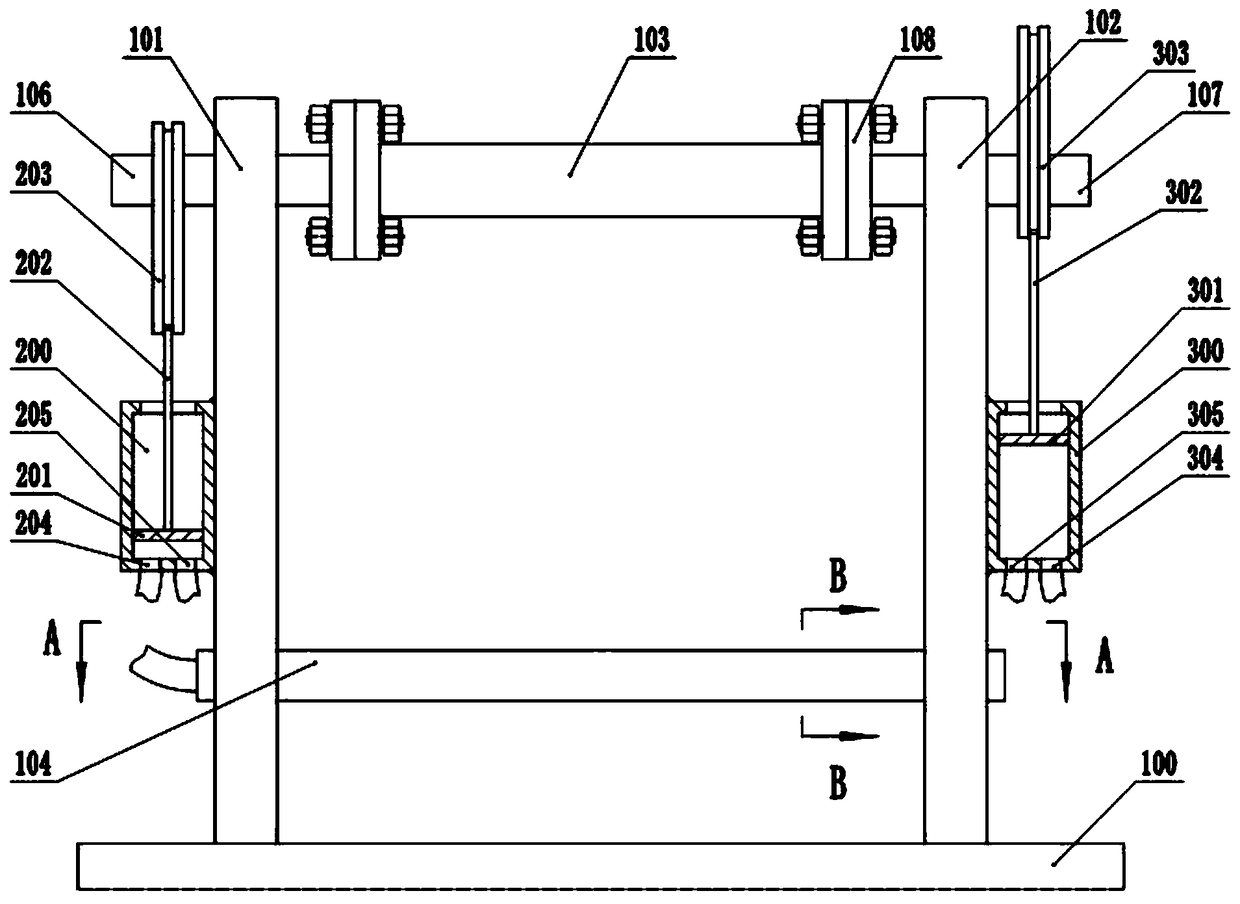

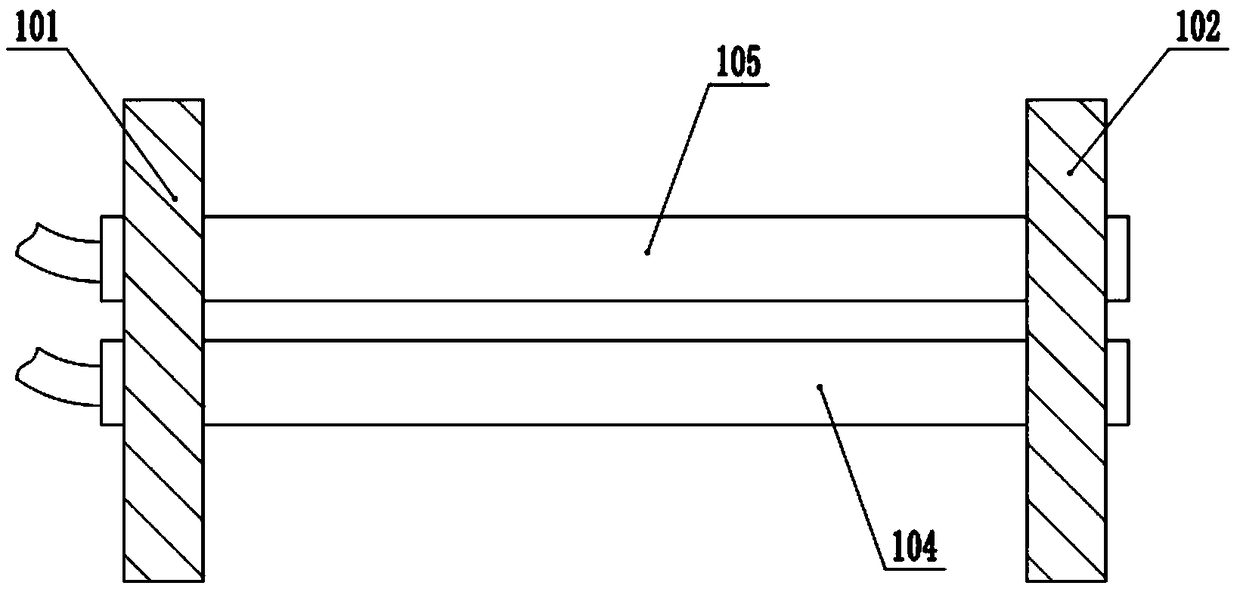

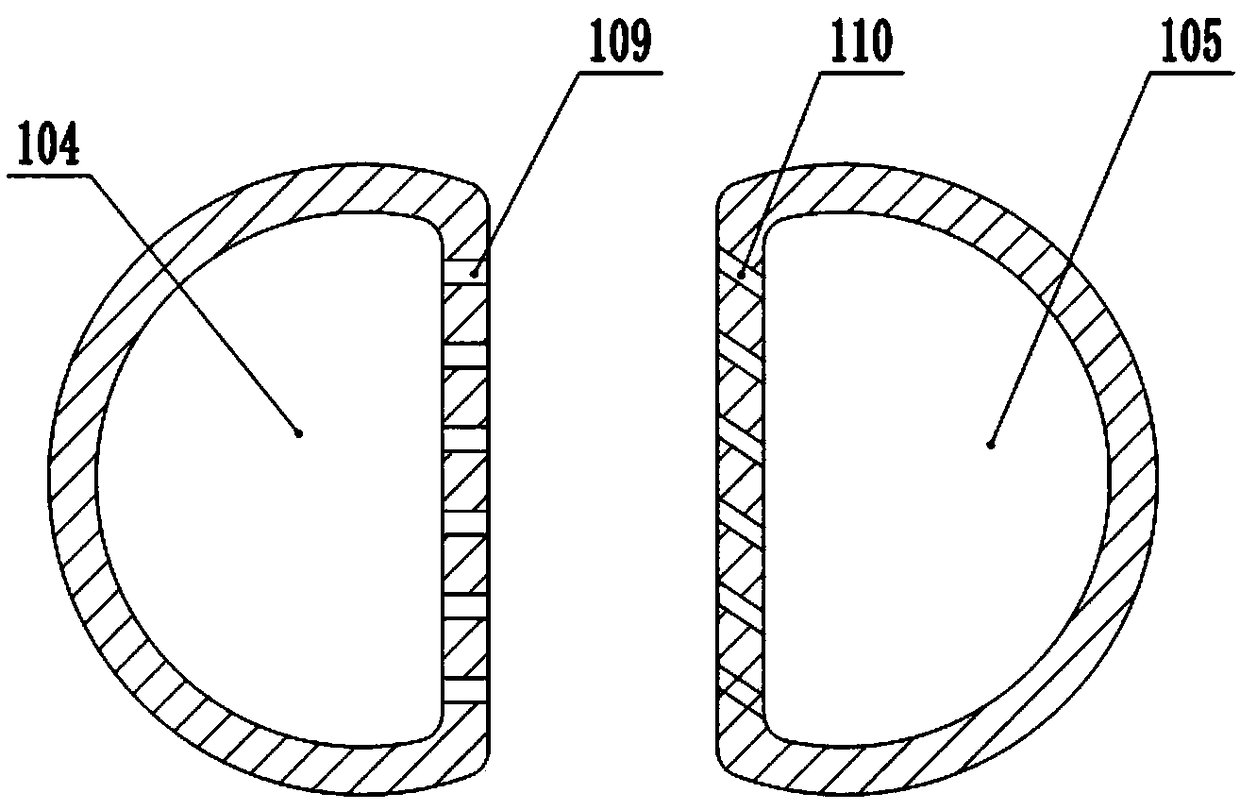

[0030] The reference numerals in the accompanying drawings include: workbench 100, first vertical plate 101, second vertical plate 102, rubber roller 103, first guide rod 104, second guide rod 105, first connecting roller 106, The second connecting roller 107, the flange 108, the suction hole 109, the gas outlet hole 110, the first cylinder body 200, the first piston 201, the first connecting rod 202, the first cam 203, the first gas outlet check valve 204, the first An intake check valve 205 , a second cylinder 300 , a second piston 301 , a second connecting rod 302 , a second cam 303 , a second outlet check valve 304 , and a second intake check valve 305 .

[0031] The embodiment is basically as attached figure 1 and figure 2 Shown:

[0032] The gluing machine for printed matter includes a workbench 100 and a frame fixed on the workbench 100, the frame includes a first vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com