Low-pollution air meat beating equipment

A low-pollution, air-based technology, applied in meat tenderization, processing meat, softening by beating meat, etc., can solve problems such as affecting structural stability, wasting physical strength, and numb arms, eliminating pollution, beating beef evenly, and reducing adverse effects. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

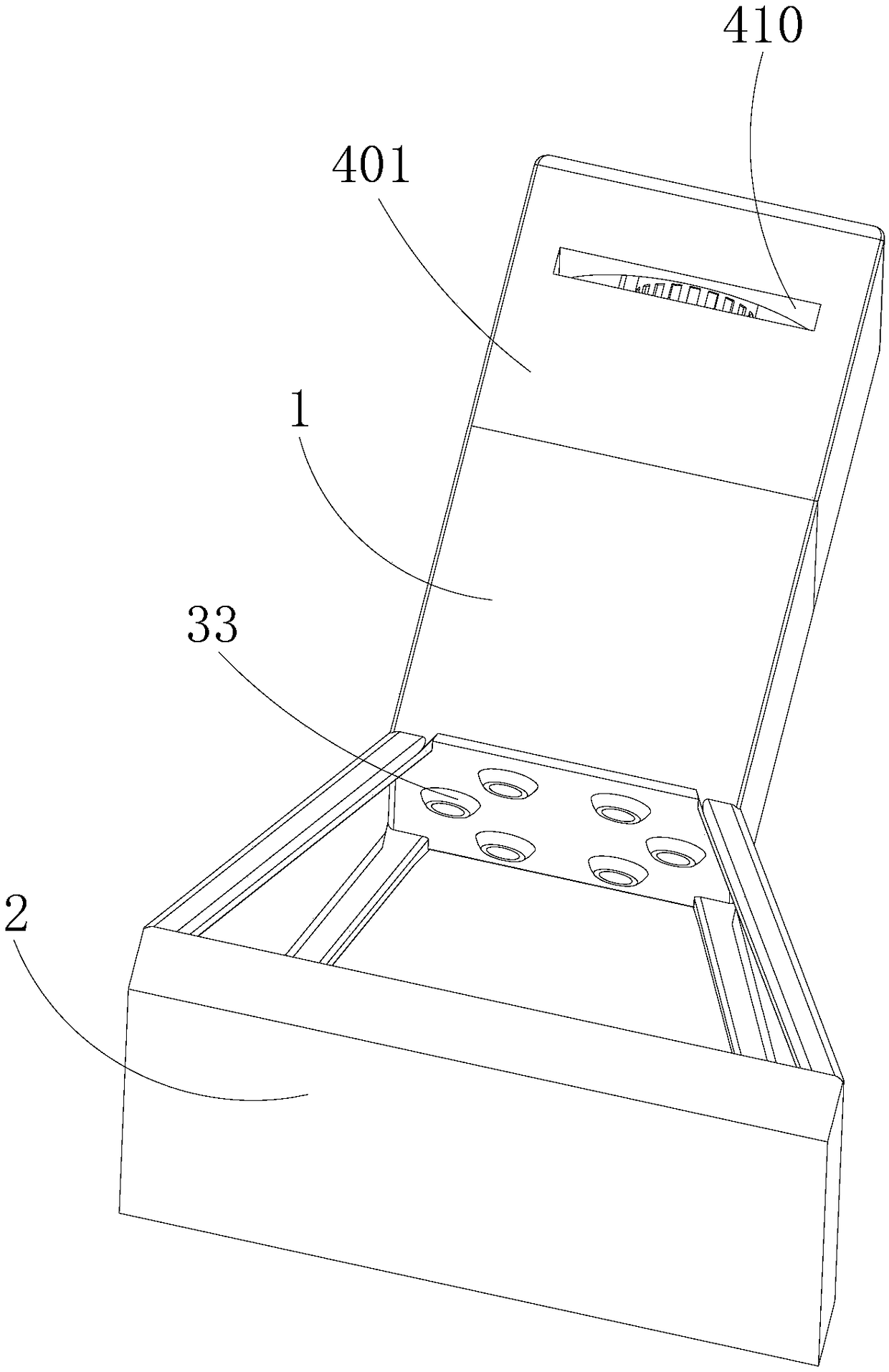

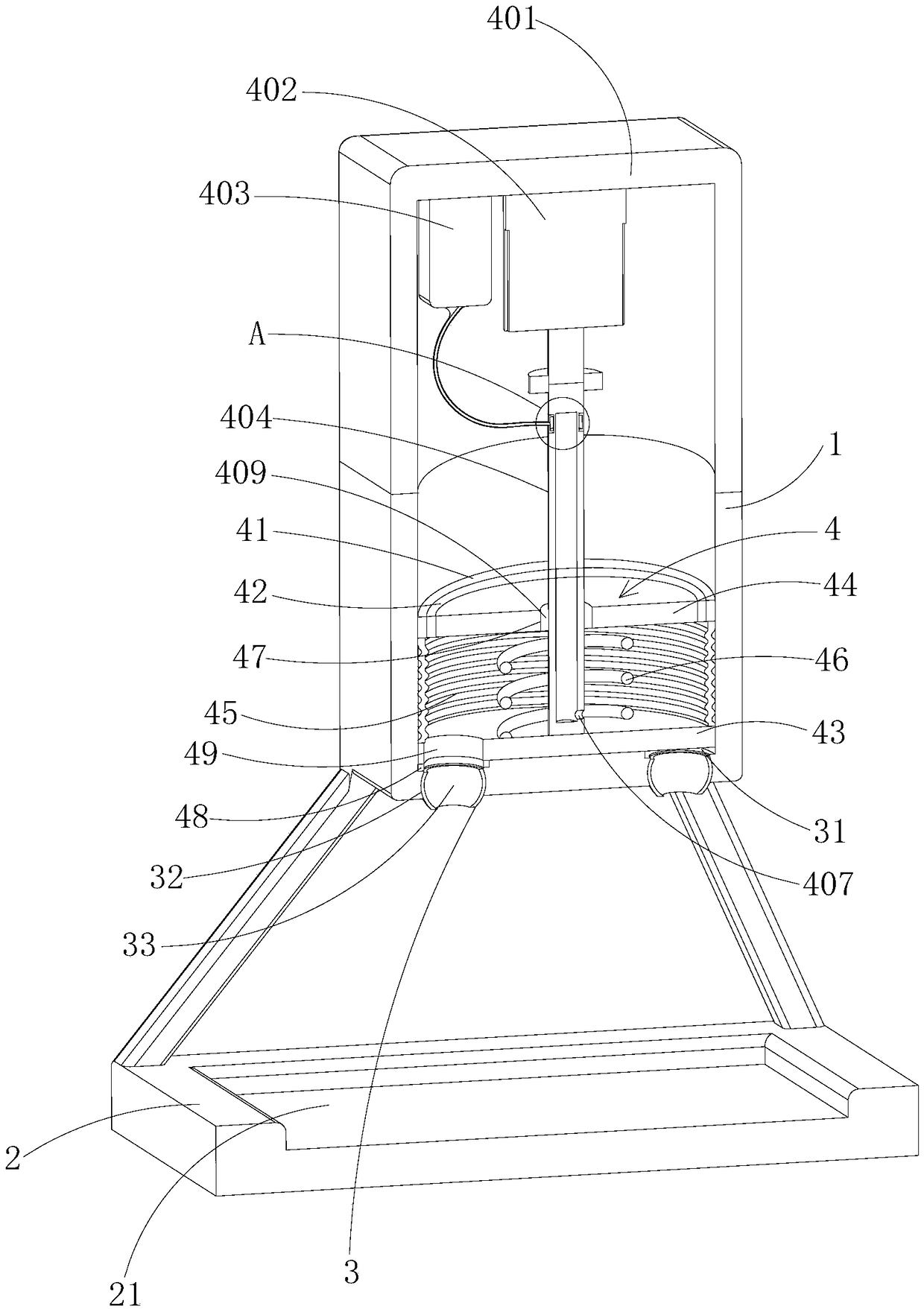

[0024] see Figure 1-4 , the present invention provides a technical solution: a low-pollution air-beating meat equipment, comprising a lower housing 1 with a cylindrical cavity inside, a backing plate 2, an air hammer mechanism 3 and an air supply mechanism 4, and the air hammer mechanism 3 is located at the bottom On the lower side of the inner wall of the housing 1, the air supply mechanism 4 is located on the upper surface of the air hammer mechanism 3, and the four corners of the upper surface of the backing plate 2 are respectively fixedly connected to the four corners of the lower surface of the lower housing 1 by connecting rods.

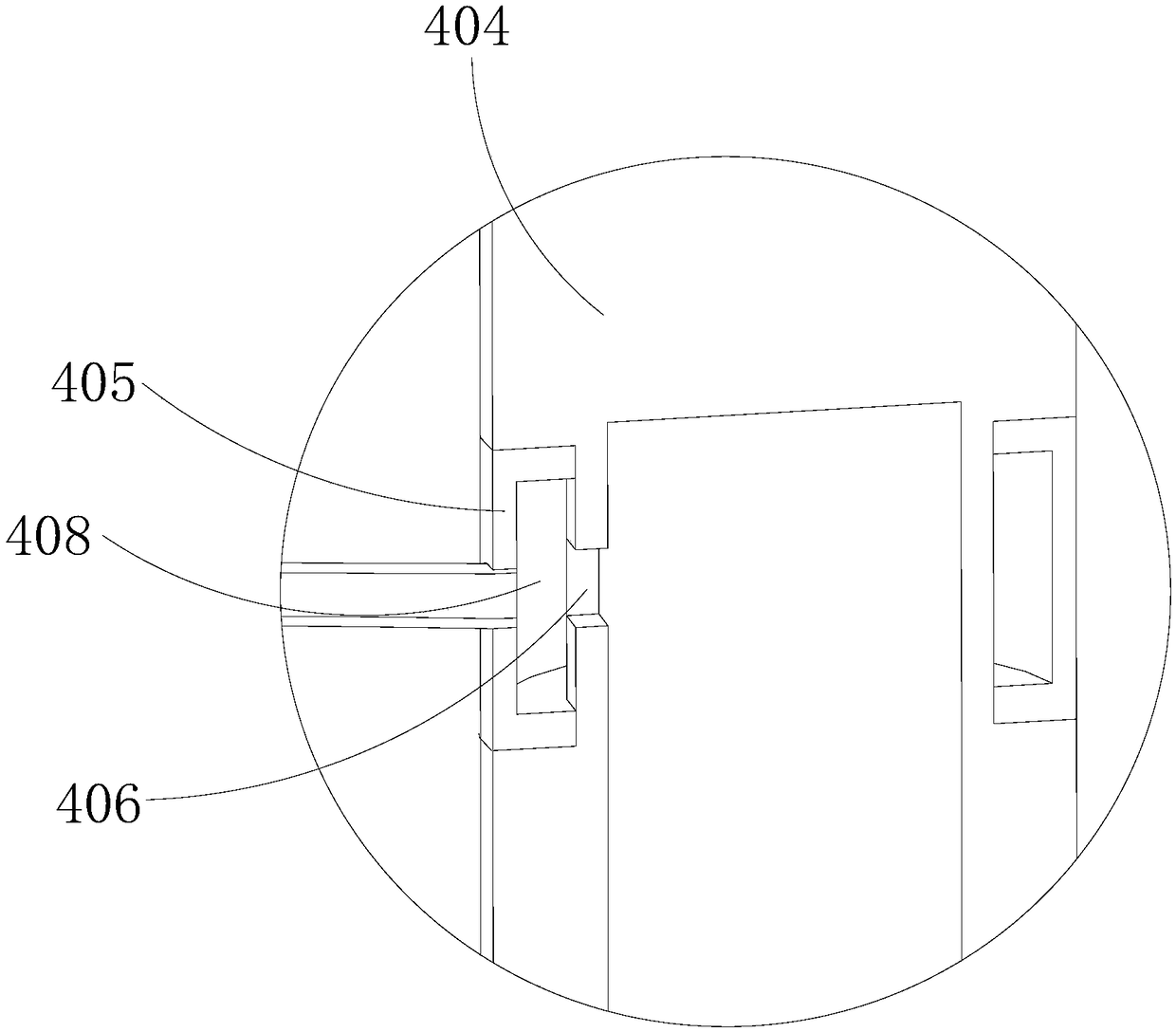

[0025] The air supply mechanism 4 includes a connecting bearing 41, a connecting ring 42, a chassis 43, a top plate 44, an annular belt 45, a return spring 46 and a sleeve hole 47, the connecting bearing 41 is fixedly sleeved on the inner side wall of the lower housing 1, and the connecting ring 42 The interference fit is inside the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com