A method for replacing insulation piercing wire clips with special-shaped and hooking wire clips under load

An insulation piercing and load-bearing technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of long-term power failure and economic loss of users, and achieve the effect of improving conductivity, increasing contact area, and shortening maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

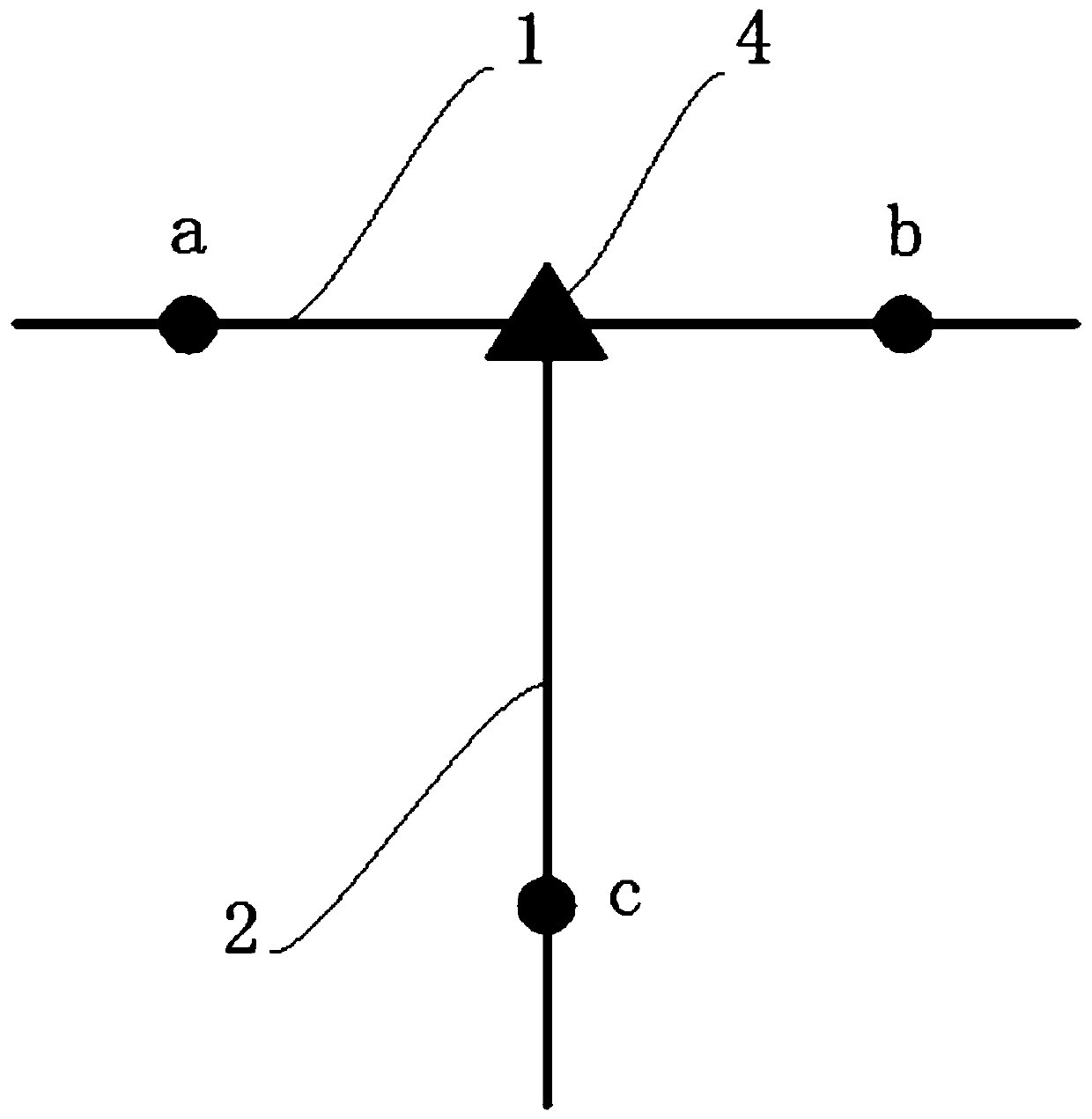

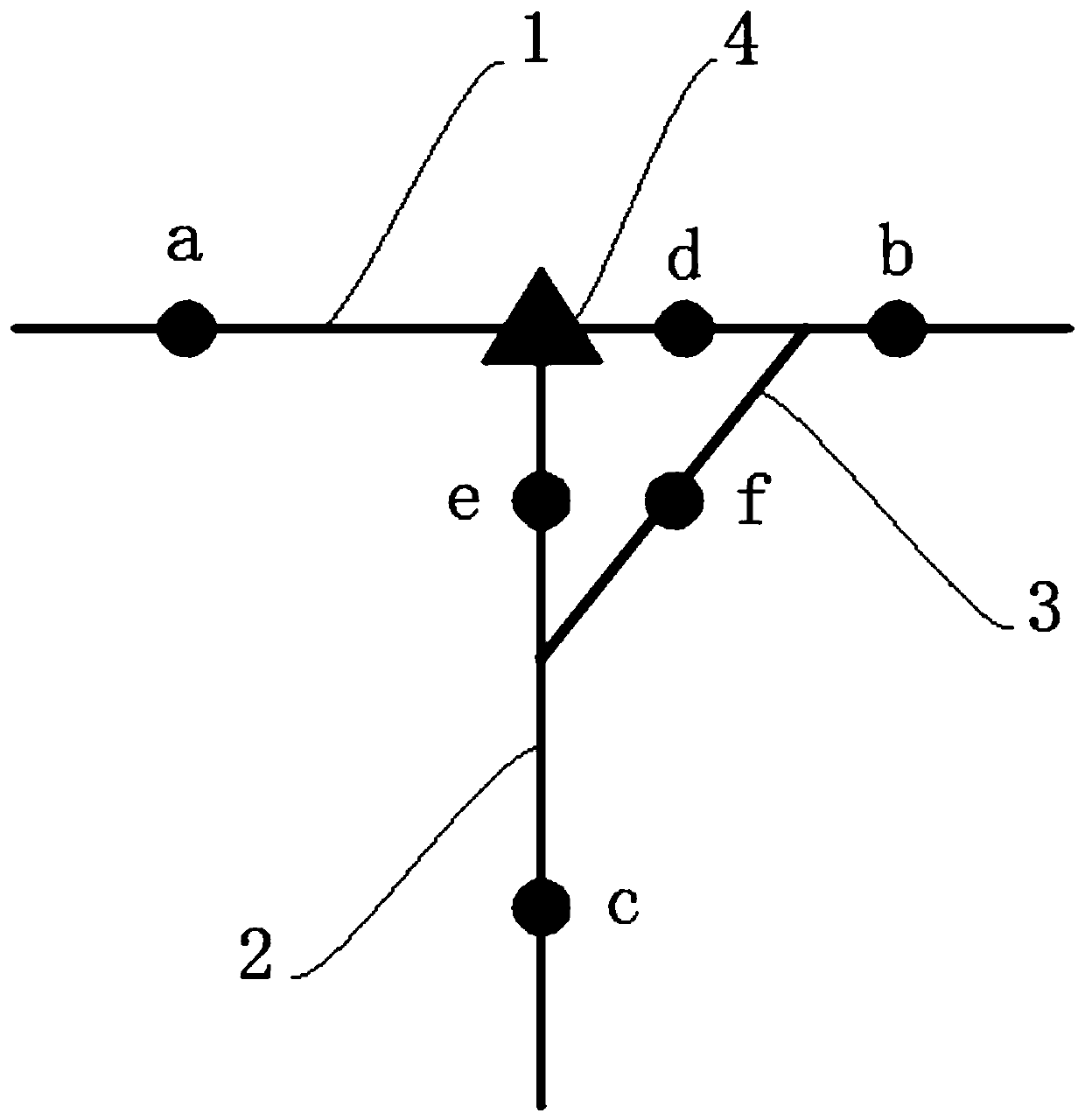

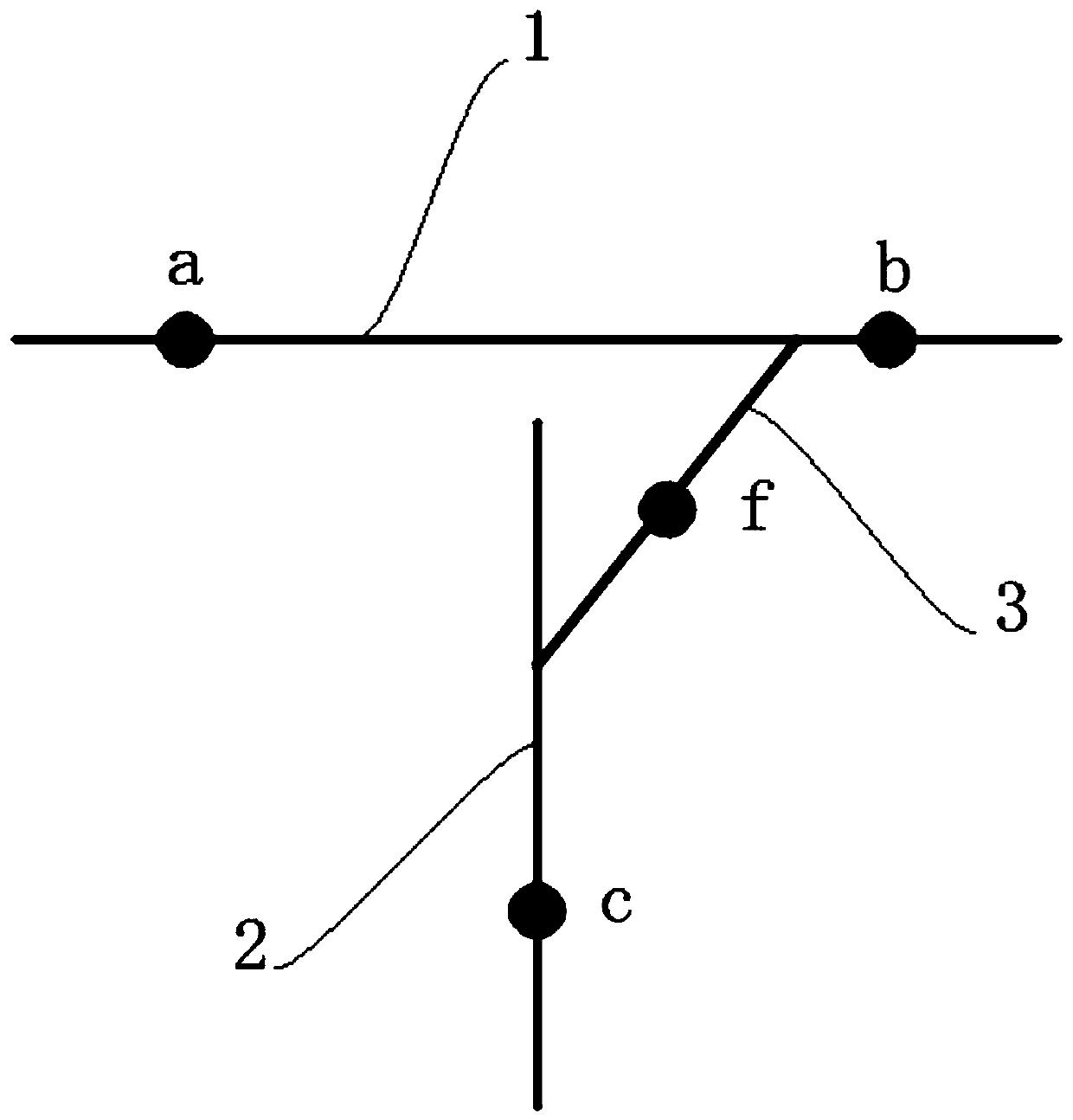

[0026] Such as Figure 1 to Figure 4 As shown, a method for replacing the insulating puncture wire clamp with load into a special-shaped and hooked wire clamp of the present invention includes the following steps:

[0027] Step 1: Use a digital multimeter to actually measure the current at points a and b of the main network wire 1 and the current at point c of the user T-connected drain wire 2 and record them. The current at point b of the main network wire 1 is used for reference verification; Whether the current-carrying capacity of the diversion line 3 meets the user's load requirements, the current-carrying capacity of the bypass diversion line 3 is selected according to the fact that the current at point a of the main network conductor 1 is greater than twice the current at the point c of the user T connected with the diversion line 2 , after determining the ampacity of the bypass drain line 3, determine the wire diameter of the bypass drain line 3 according to the ampaci...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap