Auxiliary mounting mechanism and method

A technology of installation mechanism and installation method, which is applied in the direction of building structure, building material processing, construction, etc., and can solve the problems of difficulty in controlling the construction quality and position accuracy of prefabricated wall panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

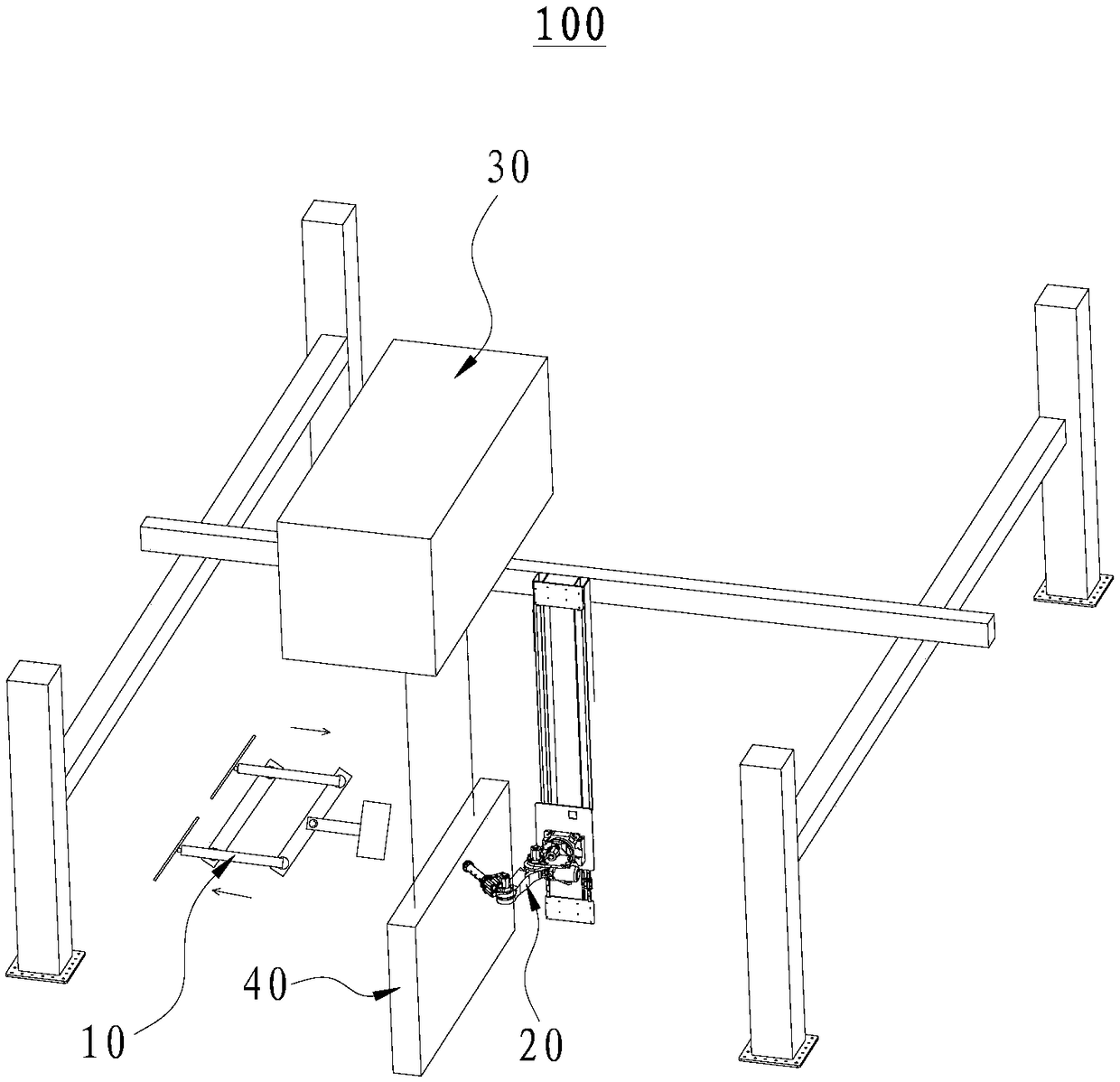

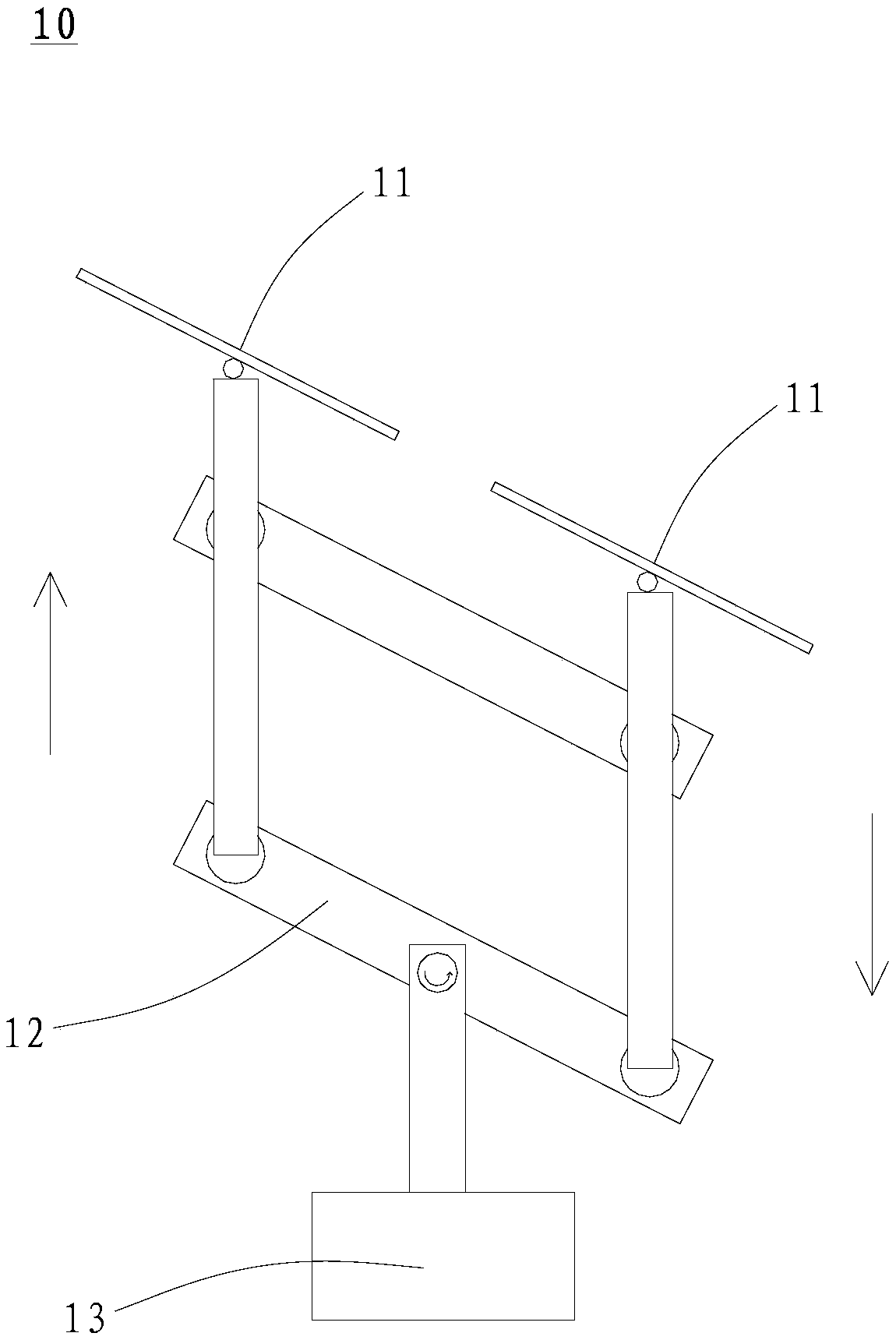

[0034] Please refer to figure 1 , which shows an auxiliary installation mechanism 100 provided by an embodiment of the present invention, which includes a control system, a hoisting system 30 and an adjustment system. The control system is used to receive electrical signals and issue control instructions to control the The hoisting system and the adjustment system work together.

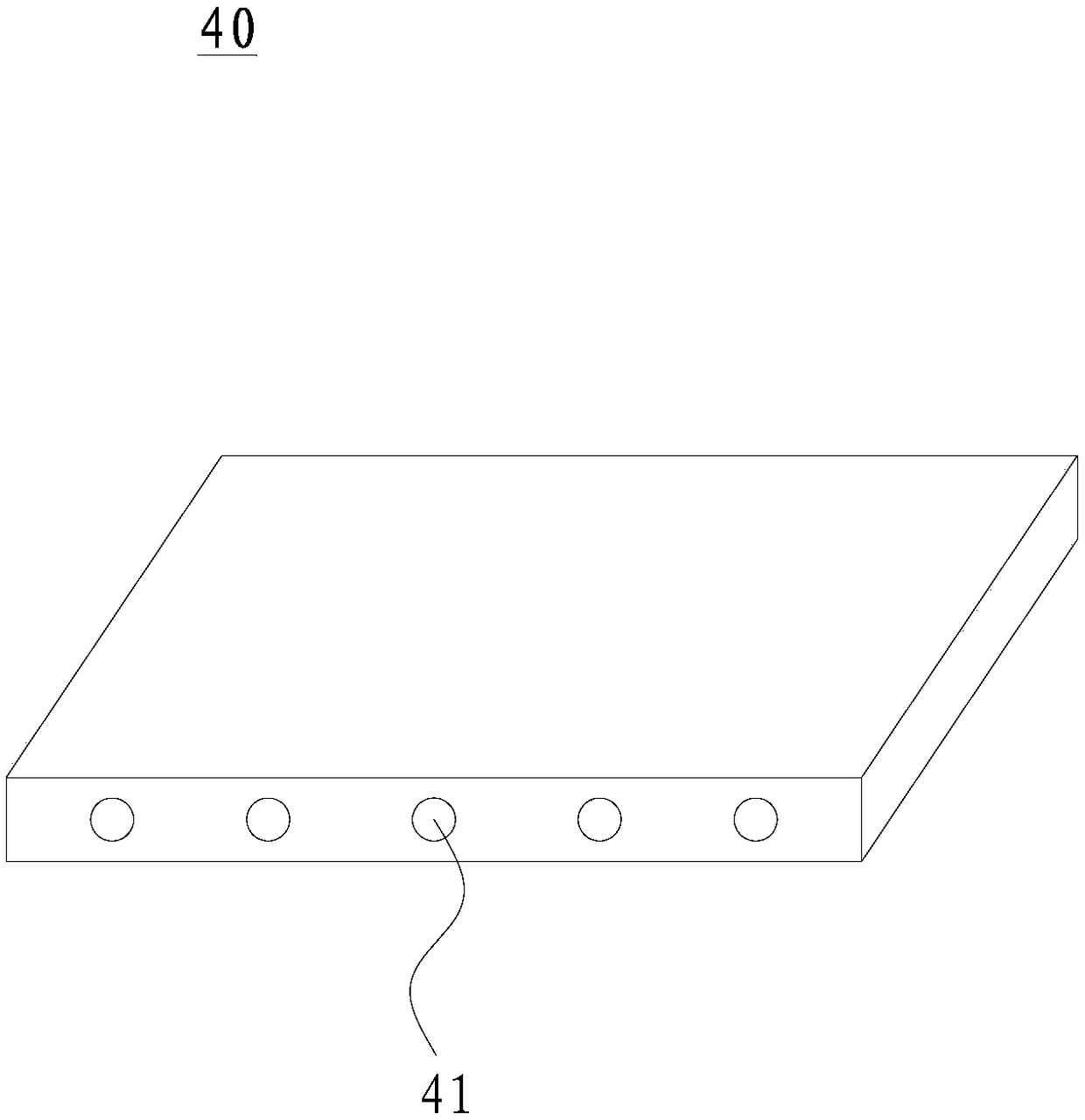

[0035] Specifically, continue to refer to figure 2 , the hoisting system 30 is hoisted with a prefabricated wall panel 40, the bottom of the prefabricated wall panel 40 is preset with a positioning hole 41, and a numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com