Safety protection mechanism for building construction elevator

A technology for safety protection and construction, applied in elevators, transportation and packaging, etc., can solve problems such as hidden safety hazards, equipment damage, and lack of safety protection devices, and achieve high safety effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

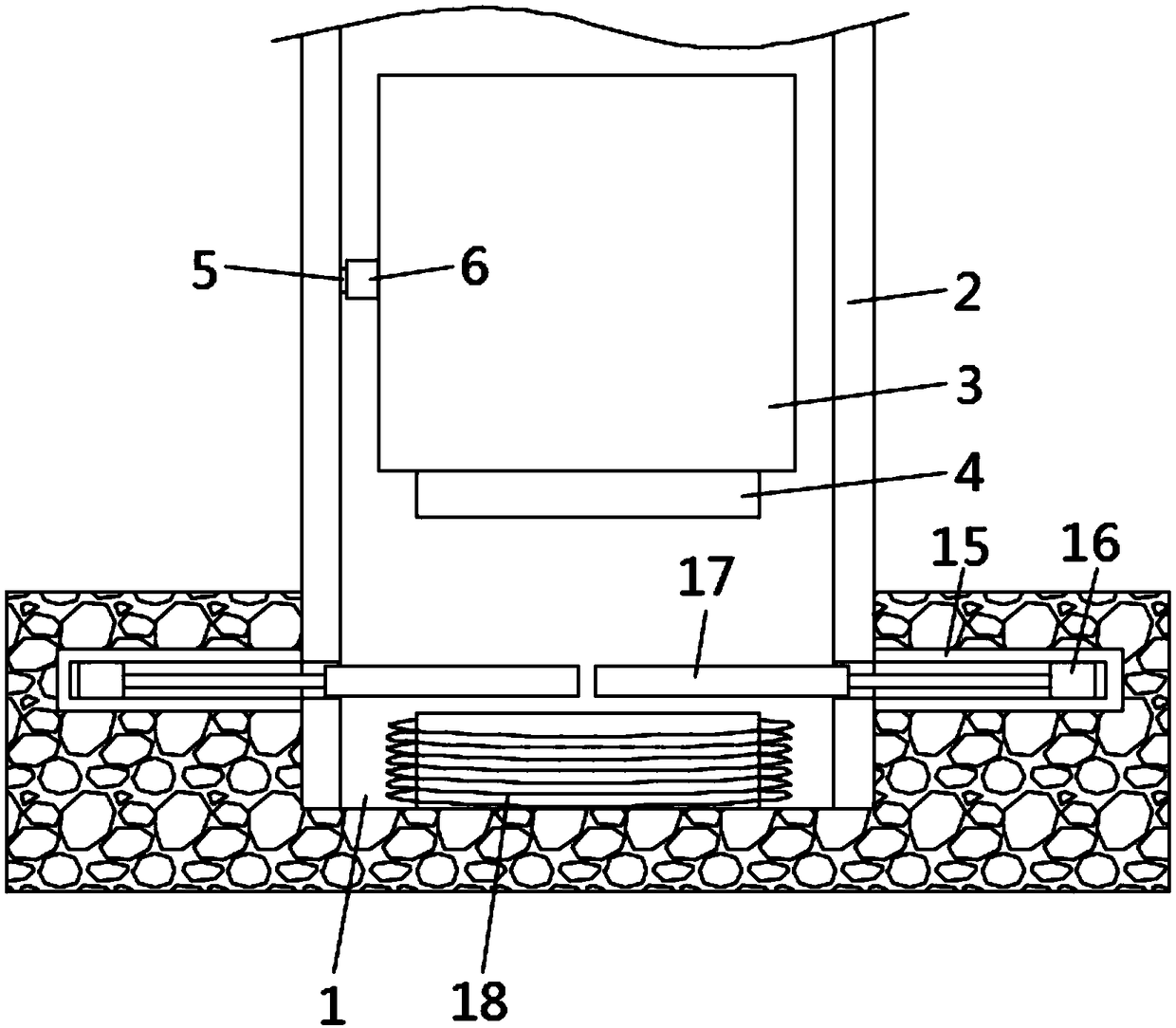

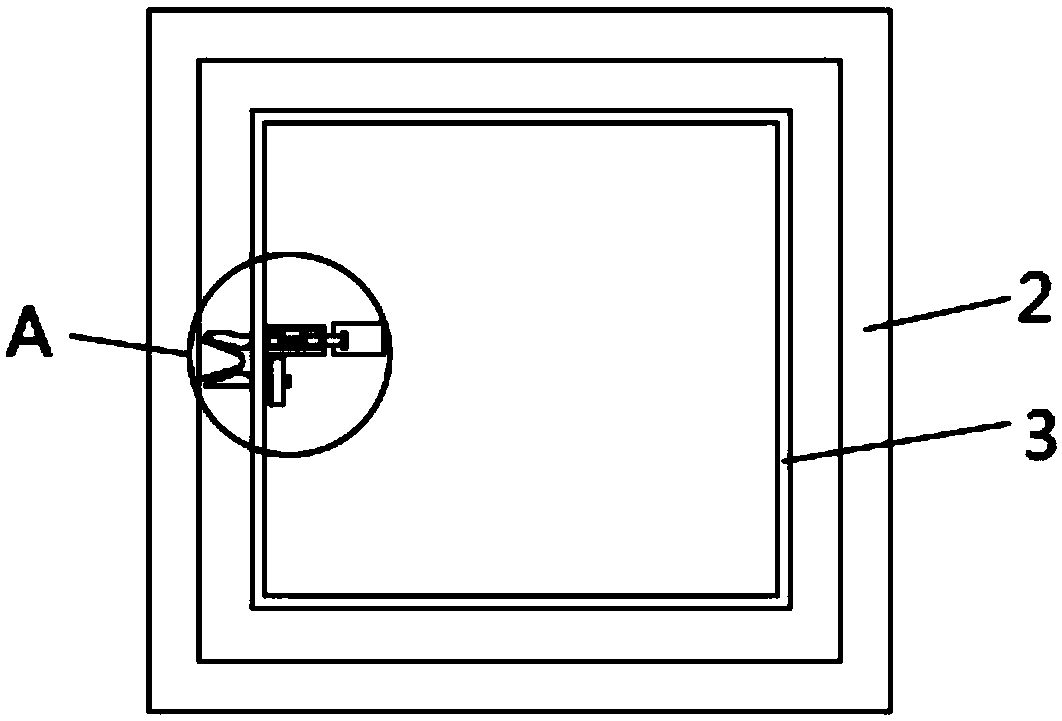

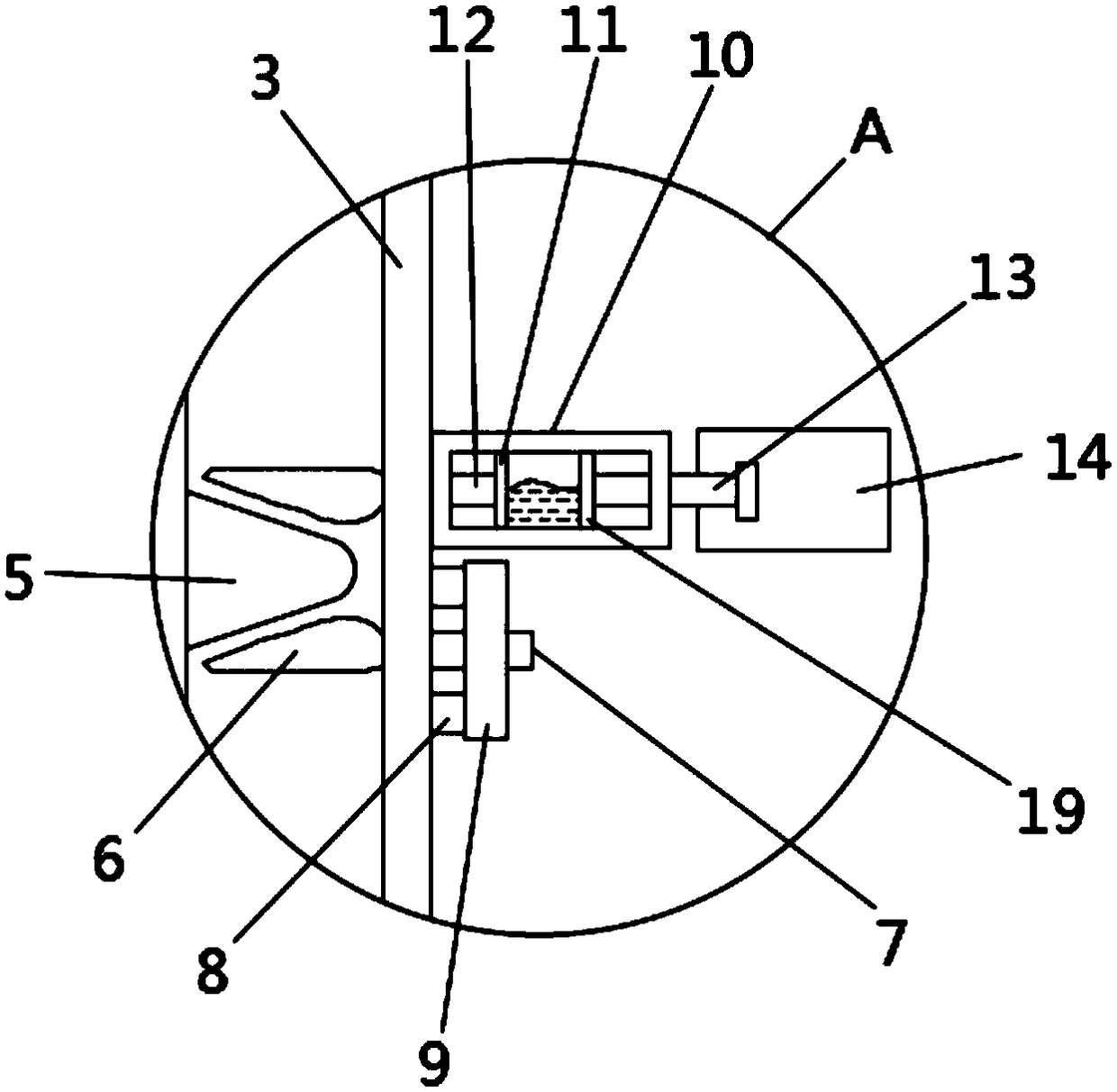

[0021] refer to Figure 1-4 , a building construction elevator safety protection mechanism, including a protective foundation pit 1, an elevator protective cover 2 and an elevator body 3, the elevator protective cover 2 is vertically installed on the inner wall of the protective foundation pit 1, and the elevator body 3 is located in the elevator protective cover In the shell 2, the inner wall of the elevator protective cover 2 is fixedly connected with a vertically arranged fixed friction strip 5, and the fixed friction strip 5 always maintains a clearance fit state with the two friction plates 6 when the elevator body 3 is in normal operation. The outer wall is fixed with friction plates 6 symmetrically with respect to the fixed friction strip 5, and the inner top of the elevator body 3 is fixed with a piston cylinder 10 and a sliding rheostat 14 at the corresponding position of one of the friction plates 6, and the piston cylinder 10 is provided with a heat conduction plug 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com