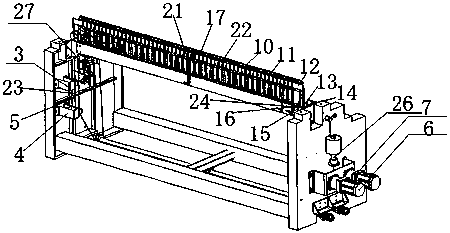

Multifunctional intelligent cloth pulling system

An intelligent spreading and multi-functional technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of uneven pressure, insufficient durability, limited diameter of rollers, etc., to improve work efficiency, The effect of high cloth quality and large feeding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

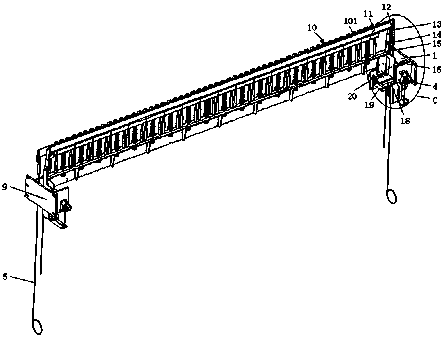

Embodiment 1

[0028] 1. When the splint A "opens" the electromagnet 18 is de-energized and released, and the splint A "closes" the electromagnet 19 is activated;

[0029] 2. The A splint 11 uses the A splint drive pin 14 as the fulcrum to perform positive lever movement, and the B splint 10 clamps the woven cloth piece one by one;

[0030] 3. A splint drives the servo motor 6 to rotate forward, drives the A splint wire rope 5 to pull the A splint drive arm 15, the A splint drive pin 14 and the A splint 11 move down from the initial position along the guide rail 16 simultaneously, and the B splint 10 is on the side of the A splint 11 Move down passively under action;

[0031] 4. Under the combined action of the A splint 11 and the B splint 10, the pull-down action of the woven cloth sheet is completed;

[0032] 5. A splint "closes" the electromagnet 19 is de-energized and releases, and the splint A "opens" the electromagnet 18 gets electric action;

[0033] Sixth, the A splint 11 makes a r...

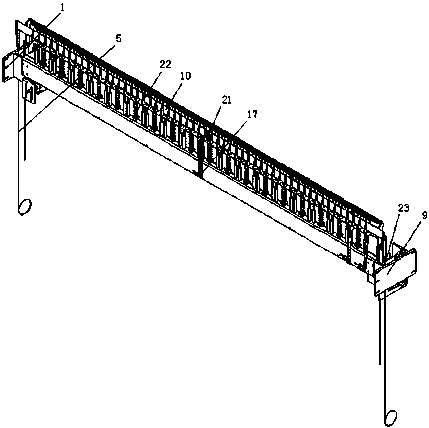

Embodiment 2

[0036]1. When the splint A "opens" the electromagnet 18 is de-energized and released, and the splint A "closes" the electromagnet 19 is activated;

[0037] 2. The A splint 11 uses the A splint drive pin 14 as the fulcrum to perform positive lever movement, and the B splint 10 clamps the woven cloth piece one by one;

[0038] 3. A splint drives the servo motor 6 to rotate forward, press down the A splint lifting spring 27 to drive the A splint wire rope 5 to pull the A splint drive arm 15, the A splint drive pin 14 and the A splint 11 from the initial position to move down along the guide rail 16 simultaneously, B The splint 10 passively moves down under the action of the A splint 11;

[0039] 4. Under the combined action of the A splint 11 and the B splint 10, the pull-down action of the woven cloth sheet is completed;

[0040] 5. A splint "closes" and the electromagnet 19 is de-energized and released, and the A splint 11 "opens" and the electromagnet 18 is powered;

[0041]...

Embodiment 3

[0044] 1. A splint 11 is "opened" and the electromagnet 18 is de-energized and released, and the splint A is "closed" and the electromagnet 19 is powered;

[0045] 2. The A splint 11 uses the A splint drive pin 14 as the fulcrum to perform positive lever movement, and the B splint 10 clamps the woven cloth piece one by one;

[0046] 3. A splint drives the servo motor 6 to rotate forward, press down the A splint to raise the counterweight 26, pull the A splint wire rope 5 to drive the A splint drive arm 15, the A splint drive pin 14 and the A splint 11 to move down from the initial position along the guide rail at the same time, B The splint 10 passively moves down under the action of the A splint 11;

[0047] 4. Under the combined action of the A splint 11 and the B splint 10, the pull-down action of the woven cloth sheet is completed;

[0048] 5. A splint "closes" the electromagnet 19 is de-energized and releases, and the splint A "opens" the electromagnet 18 gets electric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com