Circulating bucket lifting discharging device of roller press

A technology of roller press and discharging machine, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of easy leakage of materials, achieve high installation stability, convenient loading and unloading, and easy removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

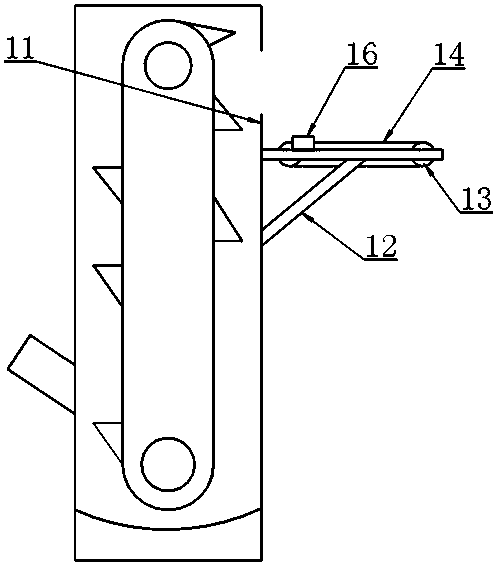

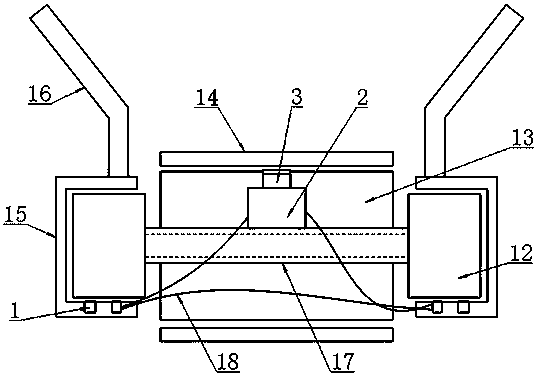

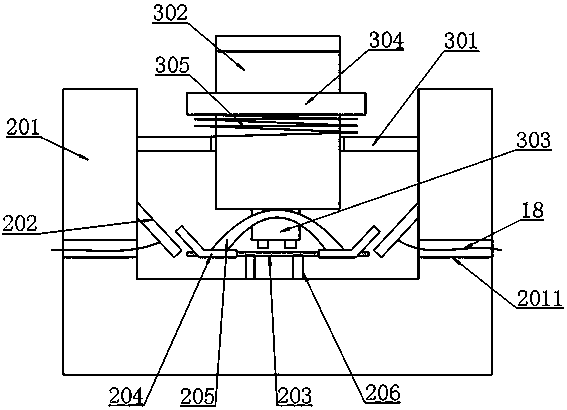

[0023] Example: as attached figure 1 , 2 , 3, 4 and attached Figure 5 As shown, a rolling bucket lifting device of a roller press includes a discharge frame 12 arranged at the position of the discharge opening 11 of the circulation bucket, pulleys 13 arranged at the positions on both sides of the discharge frame 12, and The conveying belt 14 wound on the two pulleys 13 also includes two U-shaped frames 15 respectively engaged and arranged on both sides of the discharge frame 12, and are arranged on the U-shaped frames 15 And the inclined baffle plate 16 that is used to guide the flow and discharge in the middle of the conveyor belt 14 is arranged on the inner bottom surface of the U-shaped frame 15 and is used for the electromagnetic force fixed on the discharge frame 12 by magnetic attraction. Iron unit 1, the installation beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com