Positioning method for multi-angle milling rotary clamping tool

A positioning method and multi-angle technology, applied in the field of mechanical processing tooling, can solve the problems of high stability performance of the base, low production efficiency, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

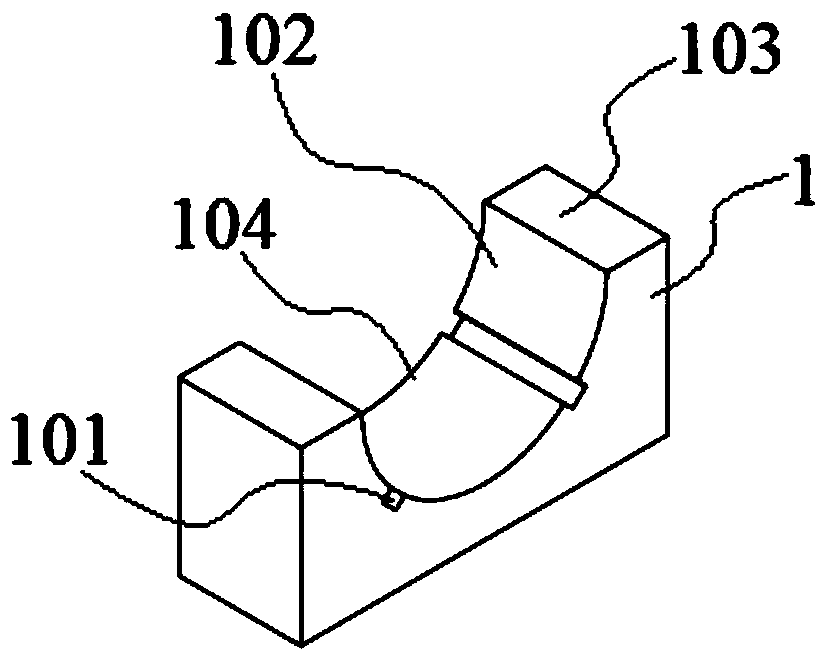

[0033] combine Figure 1-7 , the multi-angle milling rotary clamping tool of this embodiment includes a base 1, a clamp 2 and a positioning mechanism, the clamp 2 is located in the base 1, the clamp 2 and the base 1 cooperate with each other, and the positioning mechanism is stuck between the clamp 2 and the base 1.

[0034] The workpiece to be milled is placed in the fixture 2, the outside of the fixture 2 is wrapped by the base, and the positioning mechanism is stuck between the fixture 2 and the base 1, which plays a positioning role and prevents the fixture 2 from rotating in the circumferential direction relative to the base 1. For the purpose of fixing the workpiece, adjust the relative position of the fixture 2 and the base 1, and through the fixing function of the positioning mechanism, the fixed workpiece can be adjusted to rotate to different angles in the circumferential direction.

Embodiment 2

[0036] The multi-angle milling rotary clamping tool of this embodiment includes a base 1, a clamp 2 and a positioning mechanism, the clamp 2 is located in the base 1, the clamp 2 and the base 1 cooperate with each other, and the positioning mechanism is stuck between the clamp 2 and the base 1. The base 1 includes a raceway 104 and an upper end surface 103 of the base, the raceway 104 includes a base raceway surface 102, the fixture 2 is placed on the raceway 104 of a base 1, the base raceway surface 102 and The clamp 2 cooperates, and the raceway 104 of the other base 1 covers the clamp 2 .

[0037] The raceway 104 is semicircular, the base raceway surface 102 of the raceway 104 is a semicircular surface, and the clamp 2 is placed on the semicircular raceway 104 so that the clamp 2 rotates in the raceway 104, Change the angle of the workpiece in the circumferential direction, and then realize the milling of each surface of the workpiece.

[0038] The base raceway surface 102...

Embodiment 3

[0040] The multi-angle milling rotary clamping tool of this embodiment includes a base 1, a clamp 2 and a positioning mechanism, the clamp 2 is located in the base 1, the clamp 2 and the base 1 cooperate with each other, and the positioning mechanism is stuck between the clamp 2 and the base 1.

[0041] The base 1 includes a raceway 104 and an upper end surface 103 of the base, the raceway 104 includes a raceway surface 102 of the base, the fixture 2 is placed on the raceway 104 of a base 1 , the raceway surface 102 of the base is in contact with The clamp 2 cooperates, and the raceway 104 of the other base 1 covers the clamp 2 .

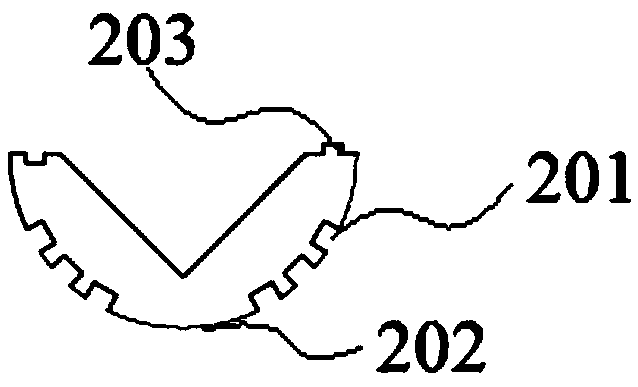

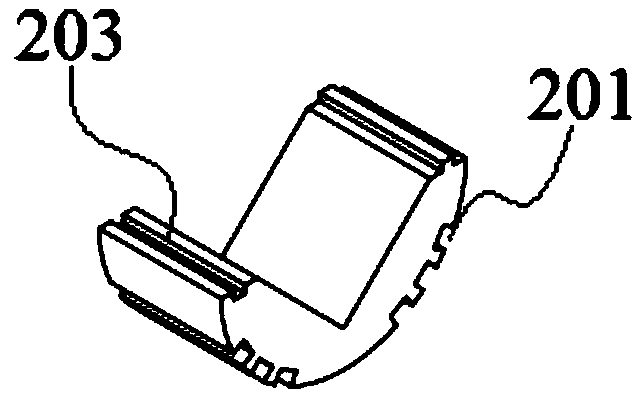

[0042] The fixture 2 includes a fixture raceway surface 202 and a fixture upper end surface 203, the fixture raceway surface 202 of one fixture 2 is matched with the base raceway surface 102 of a base 1, and the fixture raceway surface 202 of the other fixture 2 is matched with The base raceway surface 102 of the other base 1 is matched, and the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com