Feedback adjustment spraying dispensing device and adjusting method thereof

A technology of feedback adjustment and injection point, which is applied to the device and coating of the surface coating liquid, can solve the problems of unable to spray glue normally, the gap between the nozzle and the firing pin is too large, and achieve the improvement of detection reliability, creep elongation, etc. Long magnification, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

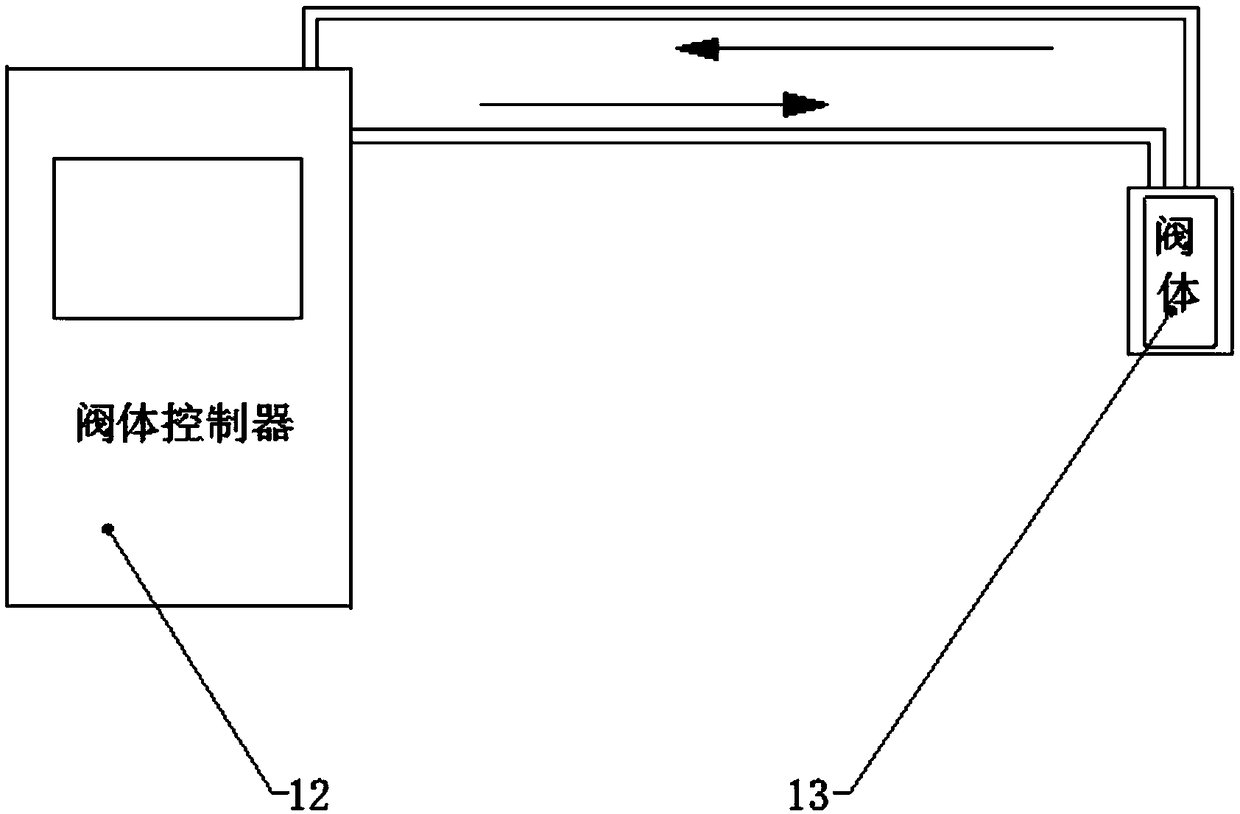

[0027] Such as Figure 1~2 , a feedback-adjusted spray dispensing device, including a valve body 13, the valve body 13 includes a valve body upper shell 3 and a valve body lower shell 2, the valve body lower shell 2 is provided with a striker hole, and the striker hole There is a striker 9 slidingly, and the lower shell 2 of the valve body is also provided with a glue feeding pipe connected to the striker hole. Connected nozzle 11, striker 9 collides with nozzle 11 to realize glue spraying,

[0028] There is a cavity inside the upper shell 3 of the valve body, a lever 5 is installed in the upper shell 3 of the valve body, a piezoelectric stack 6 is fixed on the top of the cavity, a striker 9 penetrates into the cavity and is fixed on one end of the lever 5, and the pressure The electric stack 6 is supported on the lever 5, and the striker 9 is covered with an elastic element. One end of the elastic element is supported on the lever 5, and the other end of the elastic element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com