Method and device for calibrating optical module receiving end optical power, and readable storage medium

A calibration method and optical power technology, applied in electromagnetic wave transmission systems, electrical components, transmission systems, etc., can solve problems such as large errors between optical power values and incident optical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

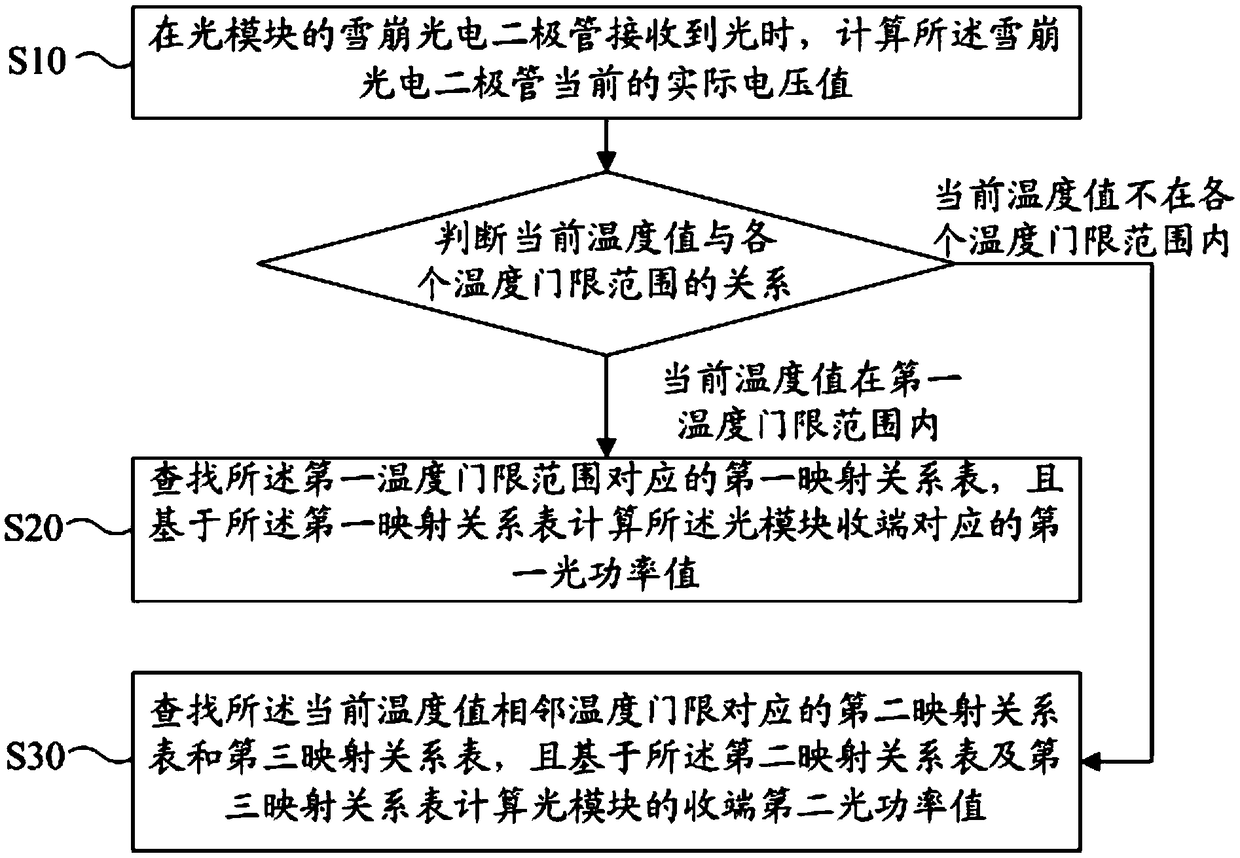

[0102] Based on the first embodiment, the third embodiment of the method for calibrating the receiving end optical power of the optical module of the present invention is proposed, please refer to Figure 4 , step S30 includes:

[0103] Step S31, calculating the first correction point based on the second mapping relationship table;

[0104] Step S32, calculating the second correction point based on the third mapping relationship table;

[0105] Step S33, calculating the second optical power value based on the first calibration point and the second calibration point.

[0106] In this embodiment, when the current temperature value is not within the range of each temperature threshold, the second mapping table and the third mapping table corresponding to the current temperature value adjacent to the temperature threshold are searched, and the first mapping table is calculated based on the second mapping table. a correction point; calculating a second correction point based on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com