Novel three-dimensional adjustable hinge

A three-dimensional, new type of technology, applied in folding panels, door/window accessories, hinges with pins, etc., can solve the problems of inability to achieve matching installation, complex installation process, complex structure of the door body, etc., to achieve simple and labor-saving installation process. The effect of stable assembly structure and high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

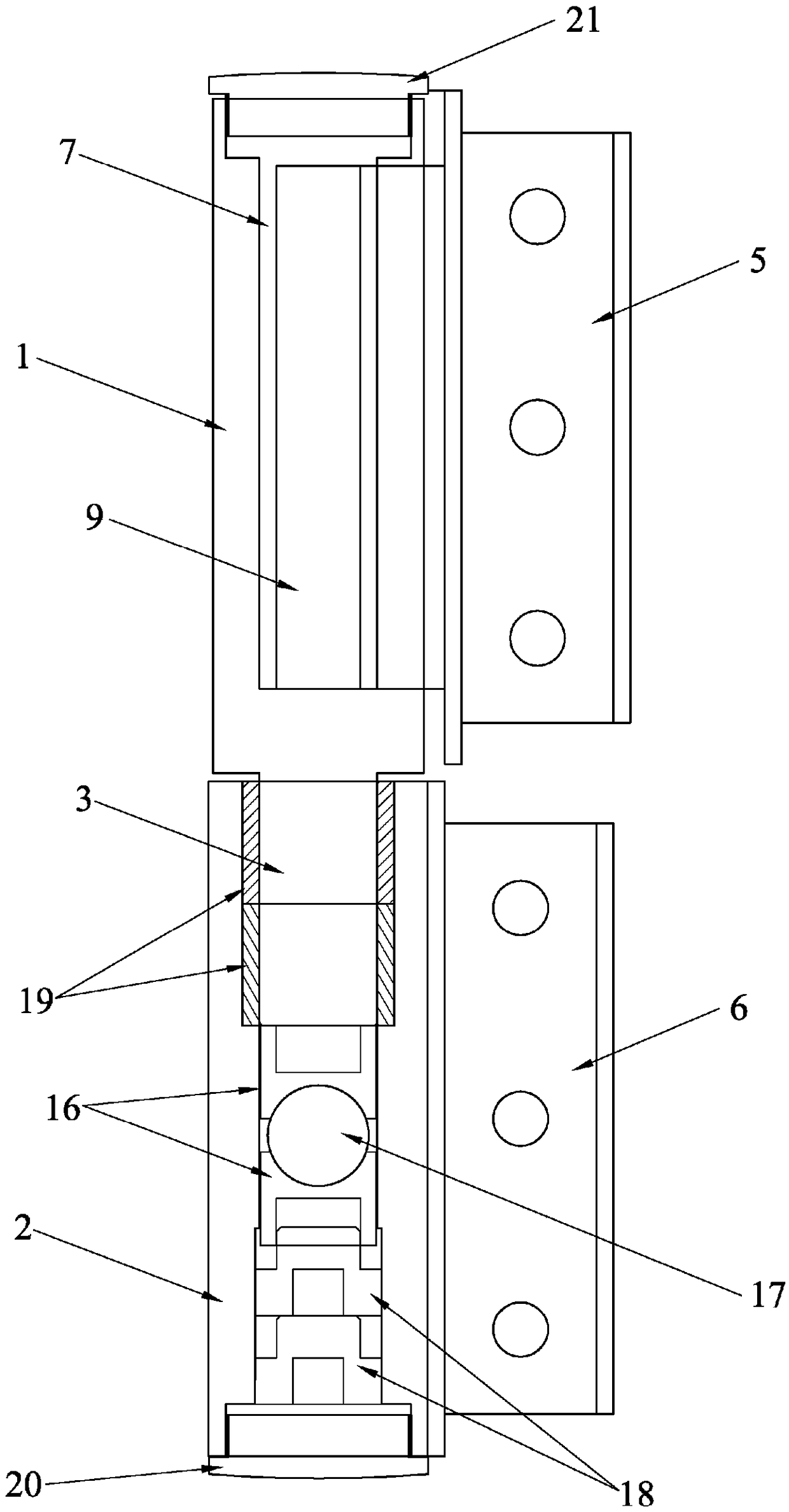

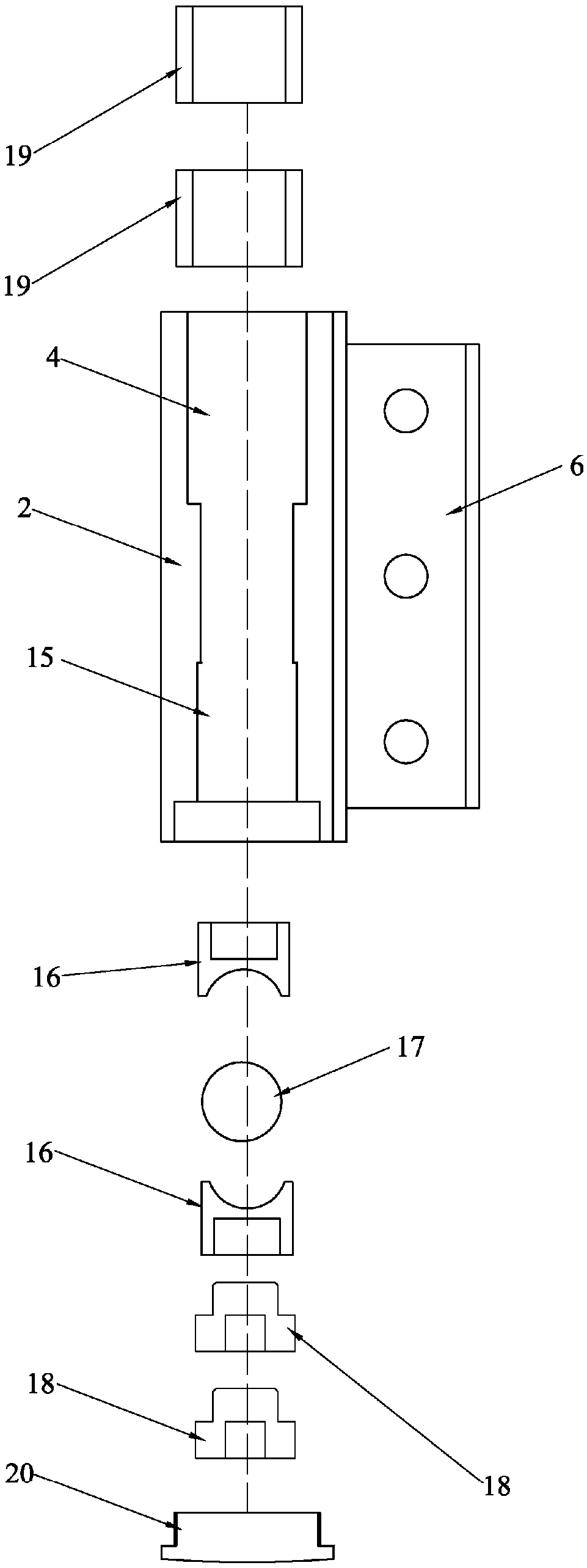

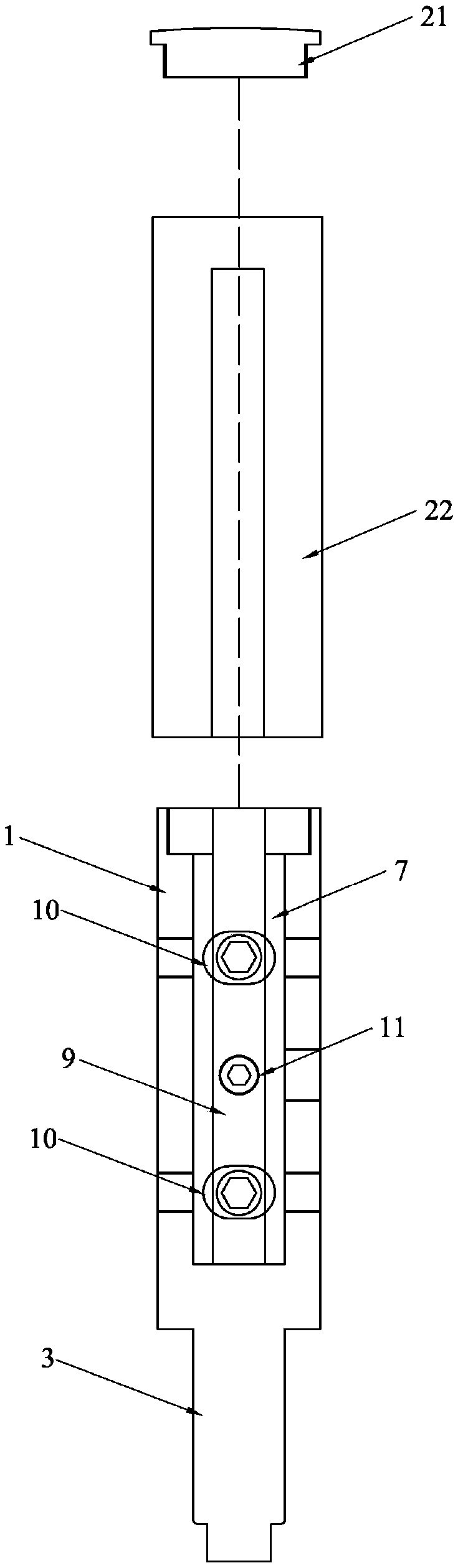

[0032] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

[0033] see Figure 1 to Figure 7 As shown, the present invention provides a new type of three-dimensional adjustable hinge, which includes a hinge body with a rotating shaft and leaves. The rotating shaft includes an upper shaft 1 and a lower shaft 2. Shaft 3, the top surface of the lower shaft is recessed with a shaft insertion groove 4, and the upper shaft is rotatably inserted into the shaft insertion groove of the lower shaft through the lower shaft, and the leaf includes The upper sheet 5 and the lower sheet 6, the upper sheet is connected to the upper shaft through its inner side, and the lower sheet is connected to the lower shaft through its own inner side, wherein the top of the upper shaft A cavity 7 is provided on the surface and a gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com