Preparation method and application of a kind of ternary composite photocatalyst

A ternary composite, photocatalyst technology, applied in the field of photocatalysis, can solve the problem of low photocatalytic performance, and achieve the effects of large specific surface area, enhanced photocatalytic performance, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 0.05 g of GO powder, add it into a beaker containing 100 ml of deionized water, and sonicate for 1 hour, so that the GO powder is uniformly and stably dispersed in the deionized water.

[0036] Add 1 g of CaIn to the above suspension 2 S 4 powder and 800 µl silver nitrate AgNO 3 aqueous solution (concentration of 40 g / L), then place the beaker in a 70-degree water-bath stirrer, and stir for 6 hours. After the reaction, filter, wash and dry.

[0037] The above dried powder was annealed in a nitrogen tube furnace at 200 °C for 2 hours to obtain Ag-RGO-CaIn 2 S 4 Composite photocatalyst, in which the content of Ag is 2 wt%, and the content of RGO is 5 wt%.

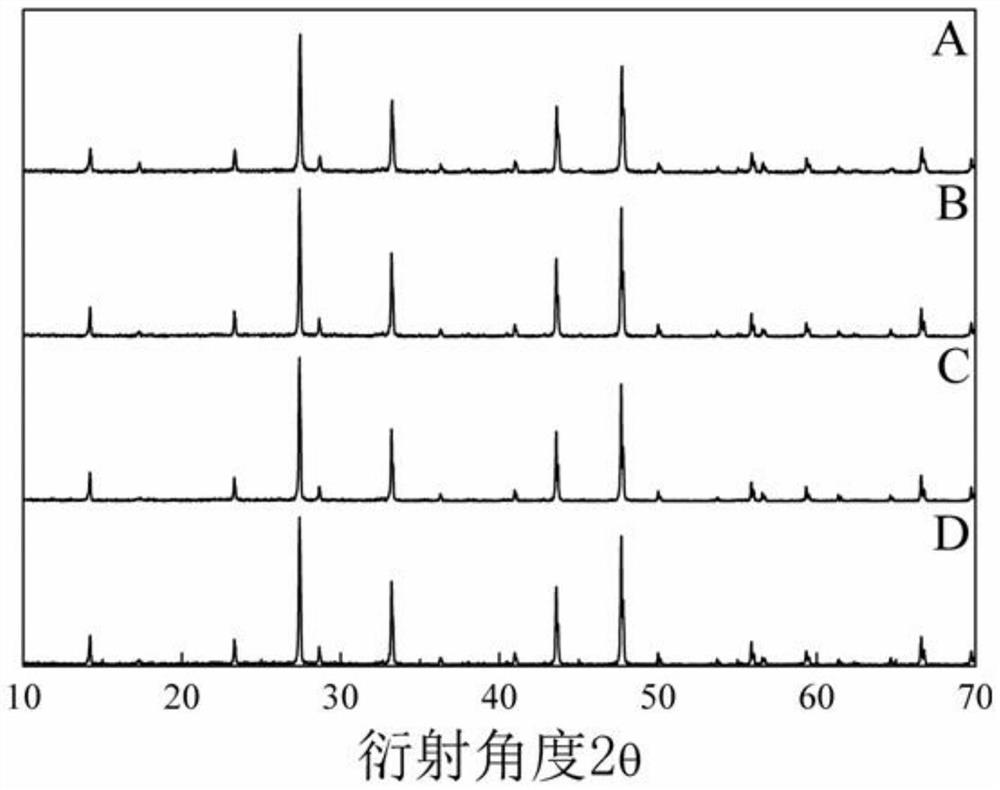

[0038] to Ag-RGO-CaIn 2 S 4 The crystal structure of the X-ray diffraction test, combined with CaIn 2 S 4 , RGO-CaIn 2 S 4 and Ag-CaIn 2 S 4 For comparison, its structure is as follows figure 1 shown. figure 1 Among them, A is cubic phase CaIn 2 S 4 The X-ray diffraction spectrum, B is RGO-CaIn ...

Embodiment 2

[0042] Weigh 0.01 g of GO powder, add it into a beaker containing 120 ml of deionized water, and ultrasonicate for 45 minutes, so that the GO powder is evenly and stably dispersed in the deionized water.

[0043] Add 1 g of CaIn to the above suspension 2 S 4 powder and 216 µl of chloroauric acid HAuCl 4 aqueous solution (concentration of 40 g / L), then place the beaker in an 80-degree water bath stirrer, and stir for 5 hours. After the reaction, filter, wash and dry.

[0044] The above dried powder was annealed in an argon tube furnace at 150°C for 3 hours to obtain Au-RGO-CaIn 2 S 4 Composite photocatalyst, in which the content of Au is 0.5 wt%, and the content of RGO is 1 wt%.

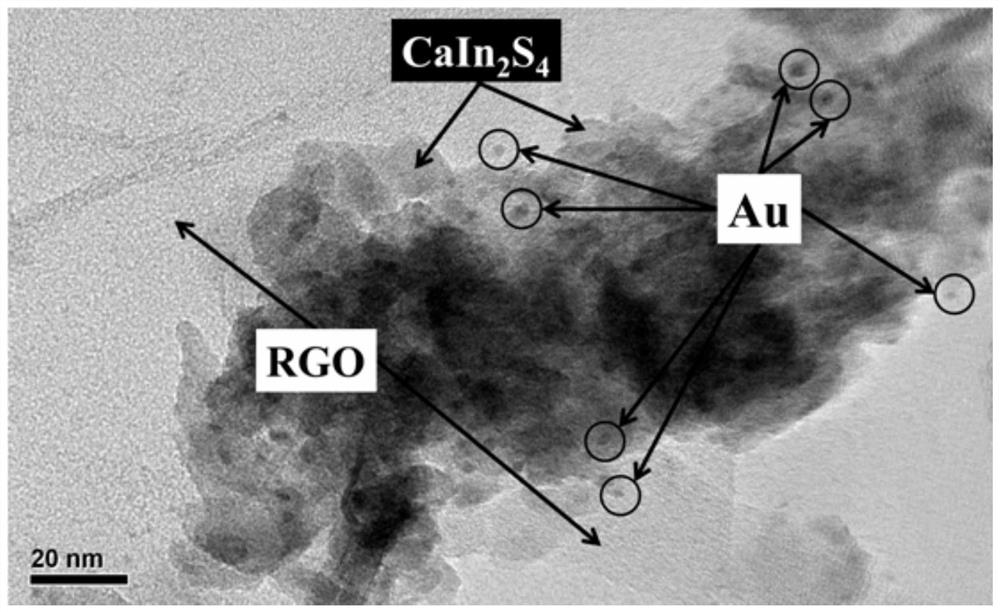

[0045] For the obtained Au-RGO-CaIn 2 S 4 The microstructure of the composite photocatalyst was analyzed by transmission electron microscopy, and the results were as follows: image 3 shown. Cubic phase CaIn 2 S 4 It has a flaky structure, and the reduced graphene oxide RGO has a two-dimens...

Embodiment 3

[0050] Weigh 0.05 g of GO powder, add it into a beaker containing 80 ml of deionized water, and ultrasonicate for 30 minutes, so that the GO powder is uniformly and stably dispersed in the deionized water.

[0051] Add 0.5 g of CaIn to the above suspension 2 S 4 powder and 1.84 ml copper nitrate Cu(NO 3 ) 2 aqueous solution (concentration of 40 g / L), then place the beaker in a water bath stirrer at 100 degrees, and stir for 4 hours. After the reaction, filter, wash and dry.

[0052] The above dried powder was annealed in a helium tube furnace at 250 °C for 1.5 hours to obtain Cu-RGO-CaIn 2 S 4 Composite photocatalyst, in which the content of Cu is 5 wt%, and the content of RGO is 10 wt%.

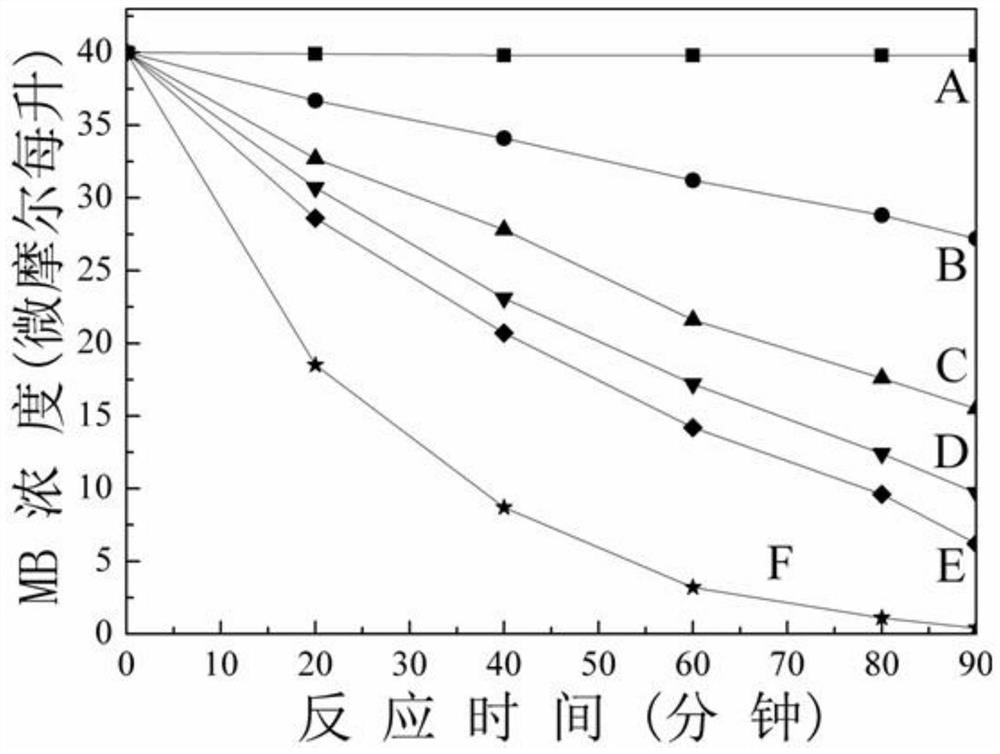

[0053] Photocatalytic degradation of toluene was used to evaluate the performance of the above photocatalysts in photocatalytic degradation of organic pollutants. The light source is a 300-watt xenon lamp (Beijing Pofilai Technology Co., Ltd., PLS-SXE300 type, the actual output power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com