High-frequency heating device

A high-frequency heating device, high-frequency technology, applied in the direction of electric heating device, microwave heating, electric/magnetic/electromagnetic heating, etc., can solve the problem of radiation distribution changes that cannot be used for high-frequency power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

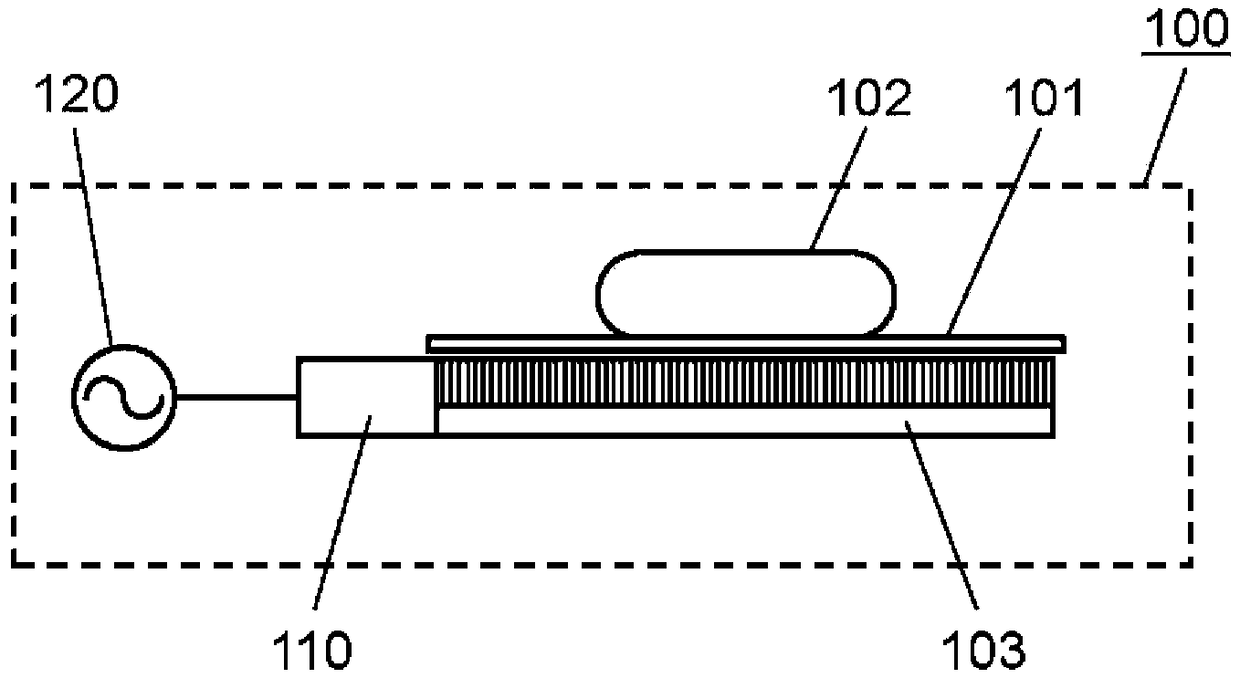

[0021] Below, use figure 1 The high-frequency heating device 100 of this embodiment will be described.

[0022] figure 1 It is a block diagram showing the basic configuration of the high-frequency heating device 100 of this embodiment.

[0023] Such as figure 1 As shown, the high-frequency heating device 100 includes a surface wave exciter 103 , a high-frequency power supply unit 110 , a high-frequency power generation unit 120 , an installation table 101 on which an object to be heated 102 is placed, and the like. The high-frequency heating device 100 heat-processes an object to be heated 102 placed on an installation table 101 .

[0024] At this time, the high-frequency heating device 100 is set so that the frequency of the high-frequency power generated by the high-frequency power generation unit 120 and the excitation frequency of the surface wave exciter 103 have a predetermined frequency relationship with each other. The intended frequency relationship is set so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com