Backlight source guide plate with lattice point

A technology of backlight and light guide plate, which is applied in the field of light guide plate, can solve the problems of poor positioning of light guide plate and light effect, inability to enhance and diffuse light, and inability to effectively use light, etc., to achieve good light guide effect, simple structure and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

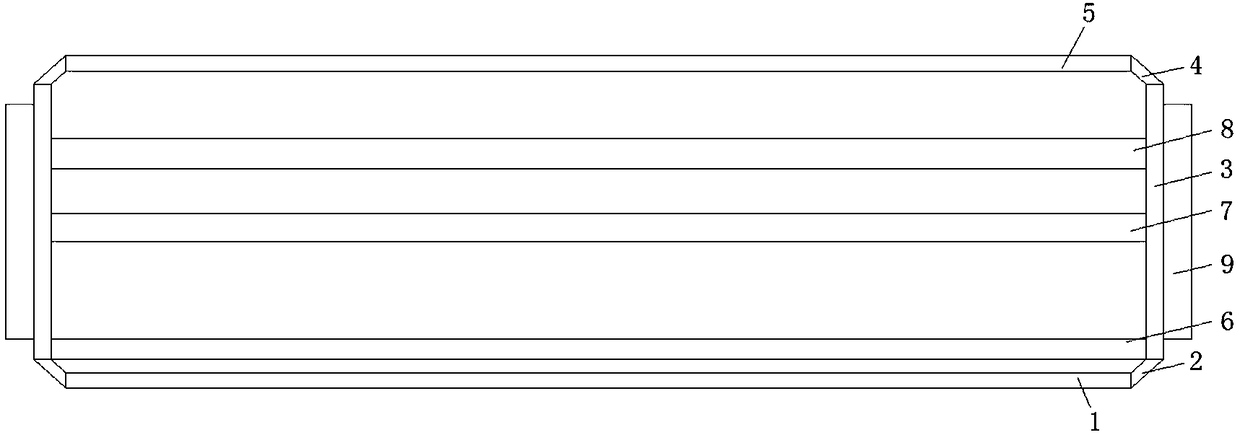

[0019] refer to Figure 1-4 , the present embodiment proposes a backlight light guide plate with network dots, including a light incident plate 1 and a light output plate 5, the light incident plate 1 and the light output plate 5 are arranged in parallel, and both sides of the light incident plate 1 and the light output plate 5 are provided with vertical The side reflector 3 provided, the side reflector 3 is provided with a first oblique reflector 2 near the light incident plate 1, the side reflector 3 is provided with a second oblique reflector 4 near the light exit plate 5, and the light incident plate 1. The first inclined reflector 2, the side reflector 3, the second inclined reflector 4 and the light-emitting plate 5 are of an integrated structure, in which a single A surface reflector 6, a diffusion plate 8 is arranged between the inner walls of the two side reflectors 3 close to the side of the light-emitting plate 5, and a brightening plate 7 is also provided between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com