An advanced sewing manufacturing process based on three-dimensional design

A technology of three-dimensional design and manufacturing process, applied in the field of sewing manufacturing process, can solve problems such as poor three-dimensional effect of clothing, and achieve the effects of stable and convenient use, reasonable and effective manufacturing process steps, and good three-dimensional space expression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

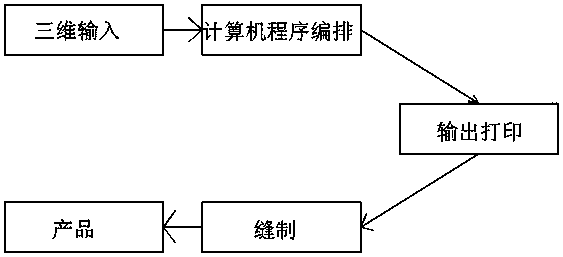

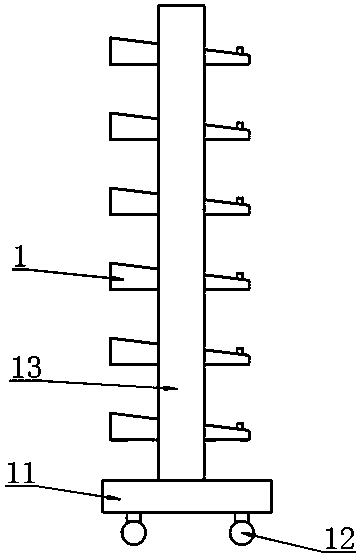

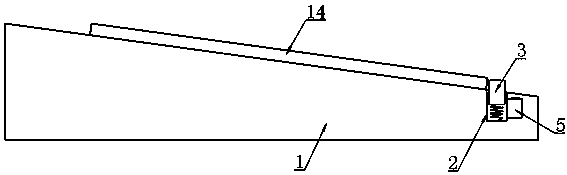

[0034] Example: as attached figure 1 , 2 , 3, 4, 5, 6 and attached Figure 7 As shown, an advanced sewing manufacturing process based on 3D design includes the following steps in sequence:

[0035] S1, 3D input, including 3D scanning input of samples and direct 3D modeling;

[0036] S2. Computer programming, including adjusting the position size, pattern color and connection relationship;

[0037] S3, output printing, including color adjustment and cutting operation after printing;

[0038] S4, sewing, and finally make a product with a strong three-dimensional sense.

[0039] In the furniture industry that manufactures products such as sofas, seats, cushions, and mattresses, there are a large number of manual cutting and sewing processes, which makes the product itself lack a three-dimensional sense, and there are too many sewing places. Manufacturing efficiency is greatly reduced.

[0040] In this embodiment, through three-dimensional input, layout adjustment, printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com