A method and system for detecting impurities in a tobacco leaf assembly line

A detection method and assembly line technology, applied in the field of tobacco industry, can solve problems such as difficulty in guaranteeing impurity removal effects, and achieve the effects of improving timeliness, reducing knowledge and experience, and ensuring requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention can be understood more clearly according to the following detailed description in conjunction with the accompanying drawings.

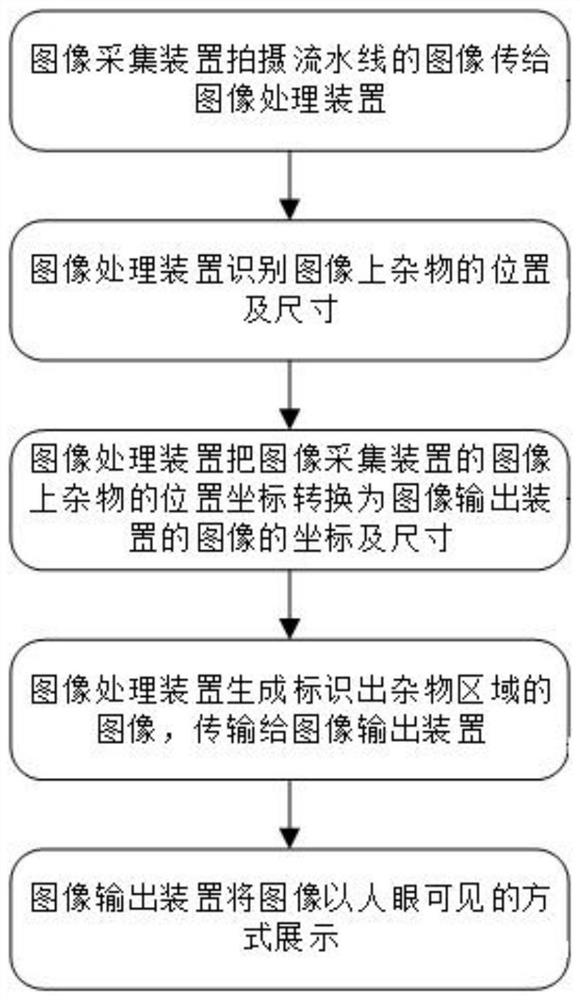

[0036] Through the images collected on the assembly line, the system projects the images marked with the position and size of the impurities onto the assembly line after impurity identification, coordinate system conversion, and image generation for the staff to identify.

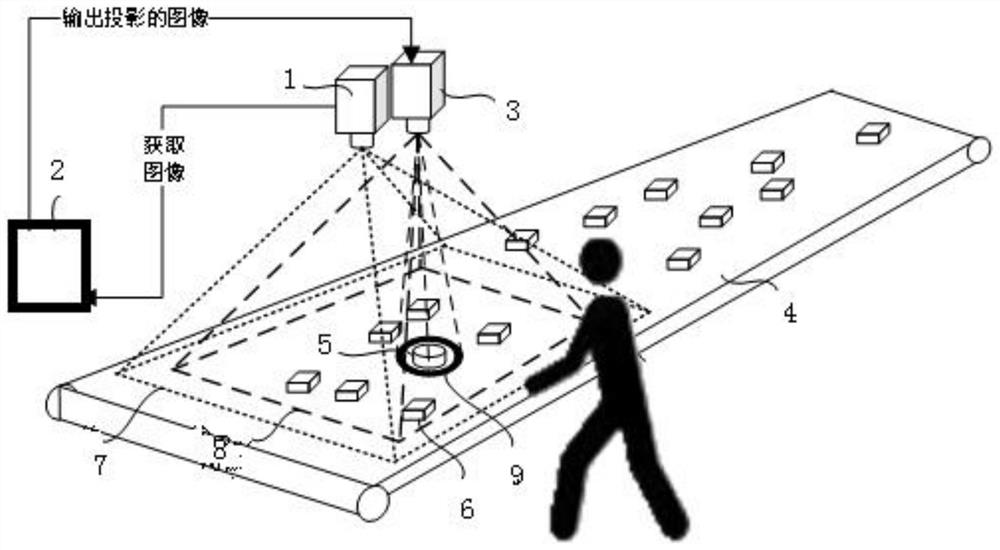

[0037] as attached figure 2 As shown, a tobacco leaf pipeline impurity detection system includes an image acquisition device 1, an image processing device 2, an image output device 3, a conveyor belt 4, impurities 5, non-impurities 6, collected images 7, output images 8 and marks 9 , the image acquisition device 1 is connected to the image processing device 2, and the image (7) of the acquisition is transmitted to the image processing device 2, and the image processing device 2 and the image output The device (3 is connected, and the output image 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com