Fault diagnosis method of rotating machinery based on adaptive multi-classified Markov Taguchi method

A technology for rotating machinery and fault diagnosis, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as property loss, adverse social impact, damaged machinery, etc., to reduce professional requirements and increase engineering Applied Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

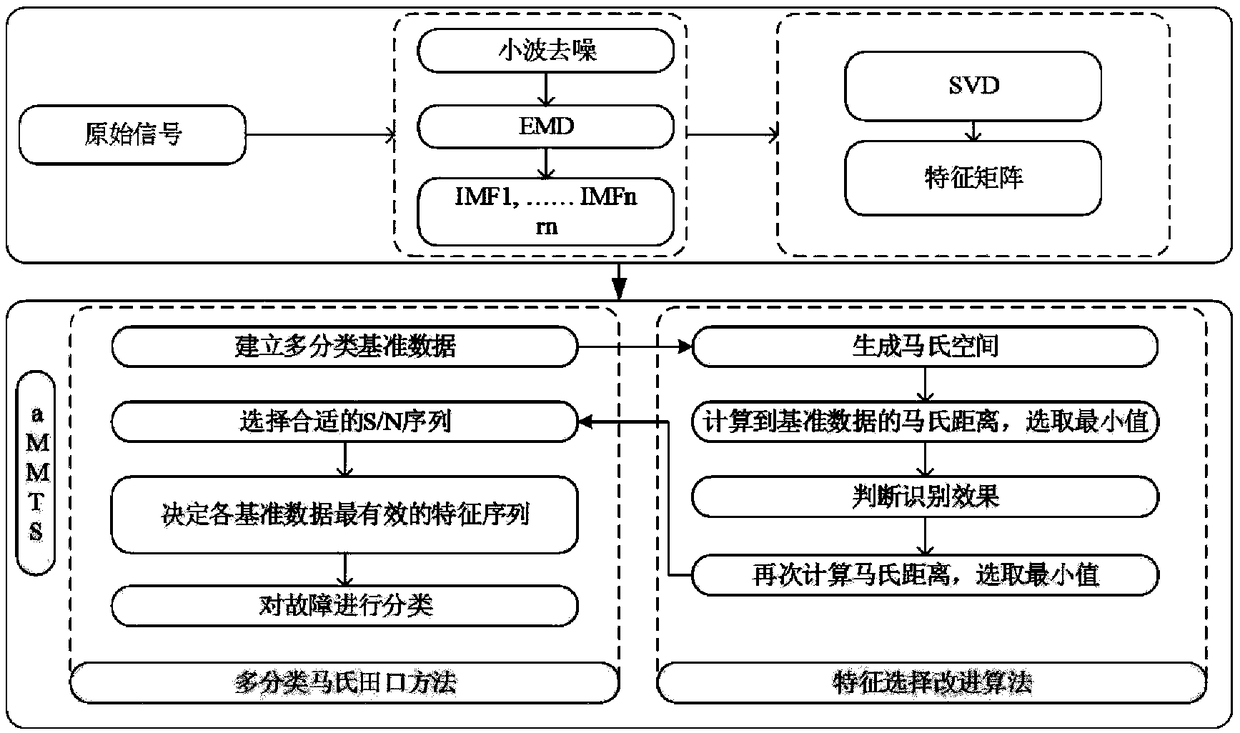

Method used

Image

Examples

example

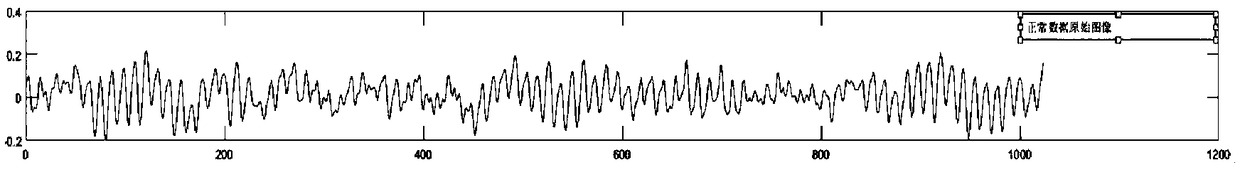

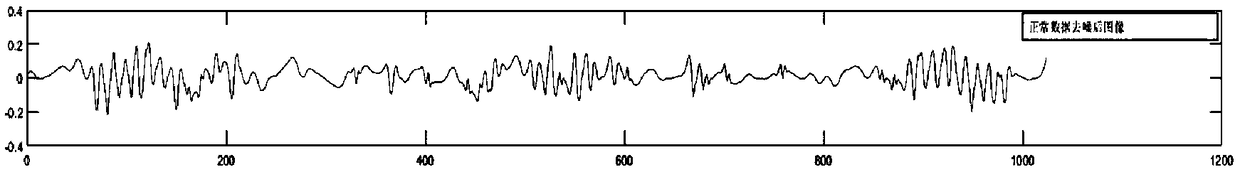

[0083] In this example, the rolling bearing fault signal provided by the Bearing Data Center of Western Reserve University is used for verification. Using sample signals under four states of normal, inner ring fault, outer ring fault and rolling element fault respectively, the present invention is based on the self-adaptive multi-classification Markov Taguchi method for detecting and verifying the rotating machinery fault diagnosis method, in order to test the present invention in practical application The role of the real situation is simulated by using the variable working condition data of the three states of inner ring fault, outer ring fault and rolling element fault of Western Reserve University. The specific steps are as follows:

[0084] Step 1: Perform EMD decomposition on the vibration signal of the bearing.

[0085] The number of signal samples in the four states is shown in Table 1.

[0086] Table 1 Number of samples in four states

[0087]

[0088] To perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com