Method for assembling middle frame and display component of electronic device, electronic device

A technology for display components and electronic equipment, applied in mechanical equipment, connecting components, measuring devices, etc., can solve problems such as heavy workload, insufficient assembly accuracy, hidden dangers of products, etc., achieve high shape accuracy, improve assembly accuracy, and reduce workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

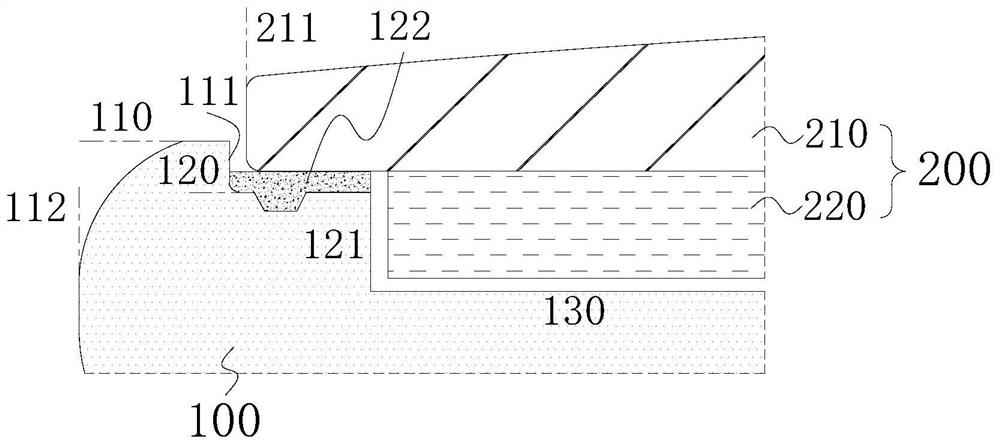

Embodiment Construction

[0041] The following describes the embodiments of the present invention in detail, and those skilled in the art will understand that the following embodiments are intended to explain the present invention, and should not be regarded as limiting the present invention. Unless otherwise specified, in the following examples that do not explicitly describe specific techniques or conditions, those skilled in the art can carry out according to commonly used techniques or conditions in this field or according to product instructions.

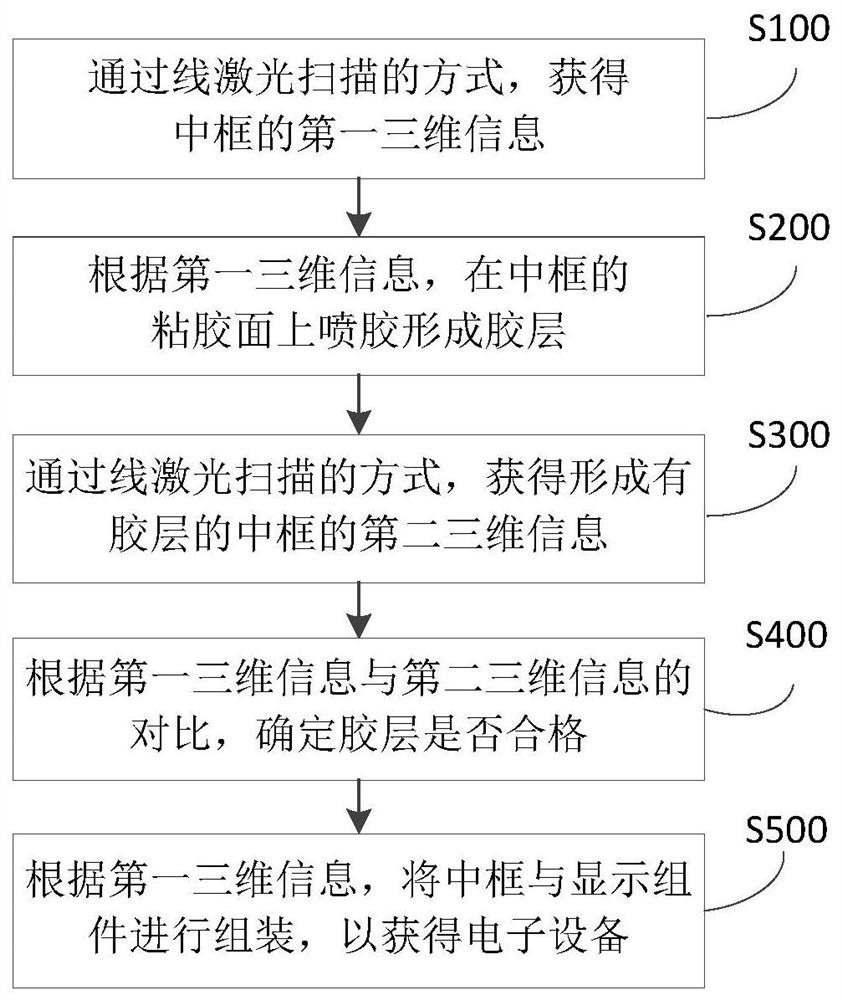

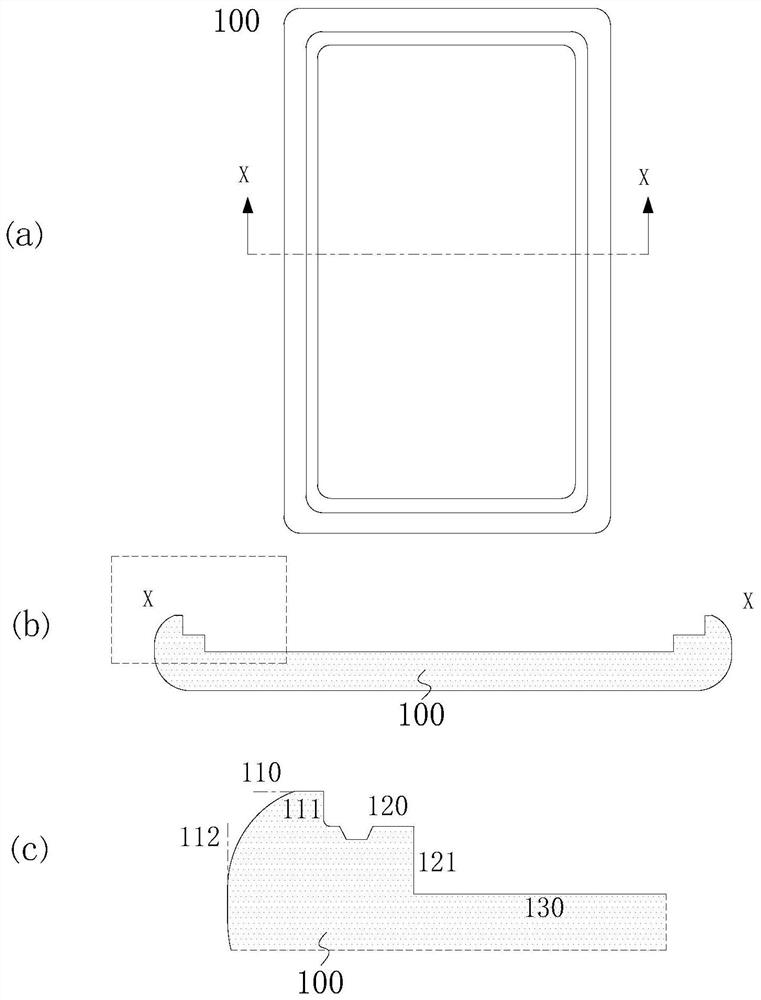

[0042] In one aspect of the embodiments of the present invention, a method for assembling a middle frame and a display component of an electronic device is provided. According to an embodiment of the present invention, refer to figure 2 , the assembly method includes:

[0043] S100: Obtain the first three-dimensional information of the middle frame by means of line laser scanning.

[0044] In this step, the original first three-dimensional informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com