Air release valve with detachable valve body and manufacturing method thereof.

A manufacturing method and technology of venting valve, which are applied in valve details, valve device, valve shell structure, etc., can solve the problems of difficult handling of valve volume slag, inability to observe fluid scouring, valve blockage, etc., and achieve the effect of reducing test costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

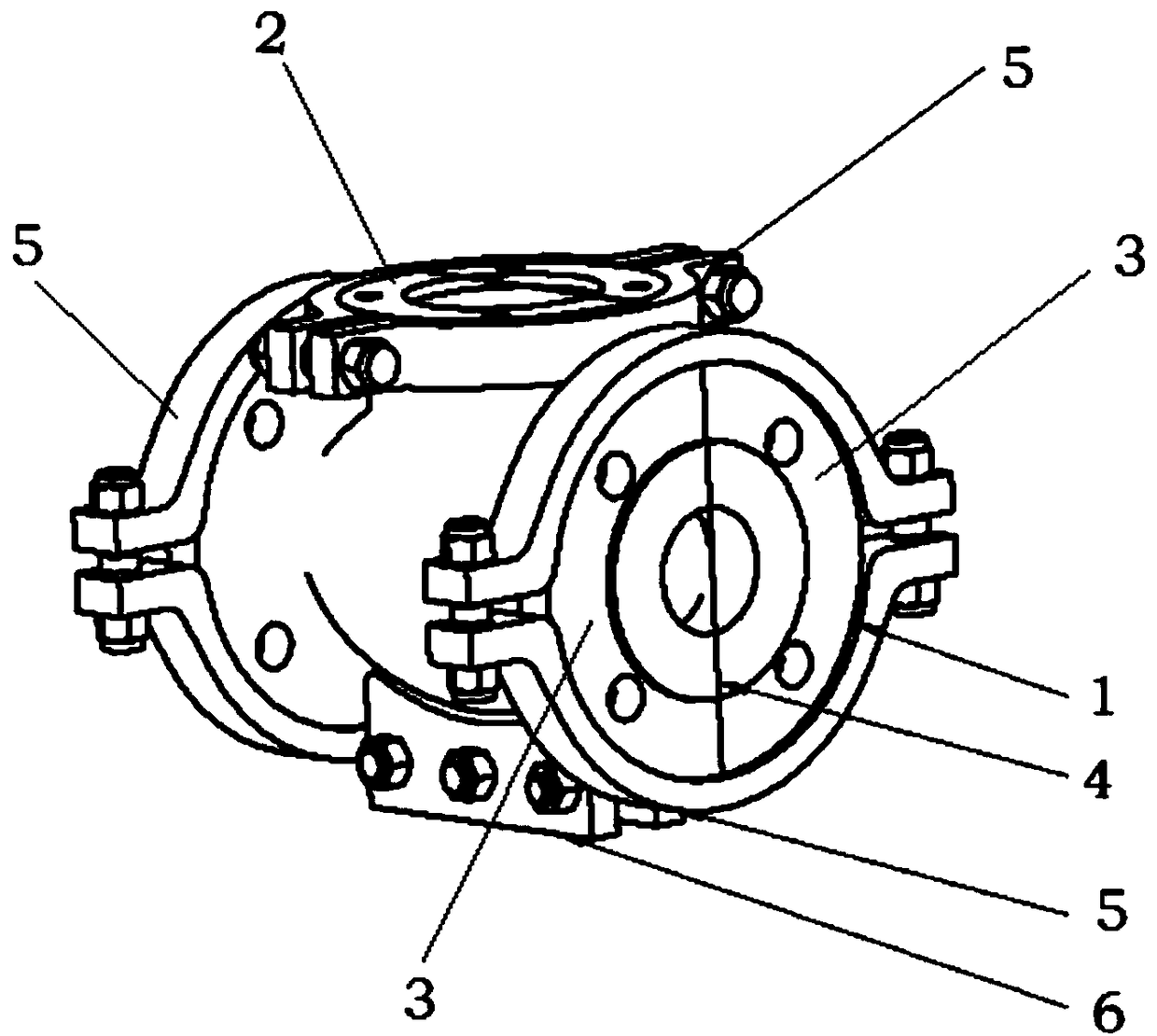

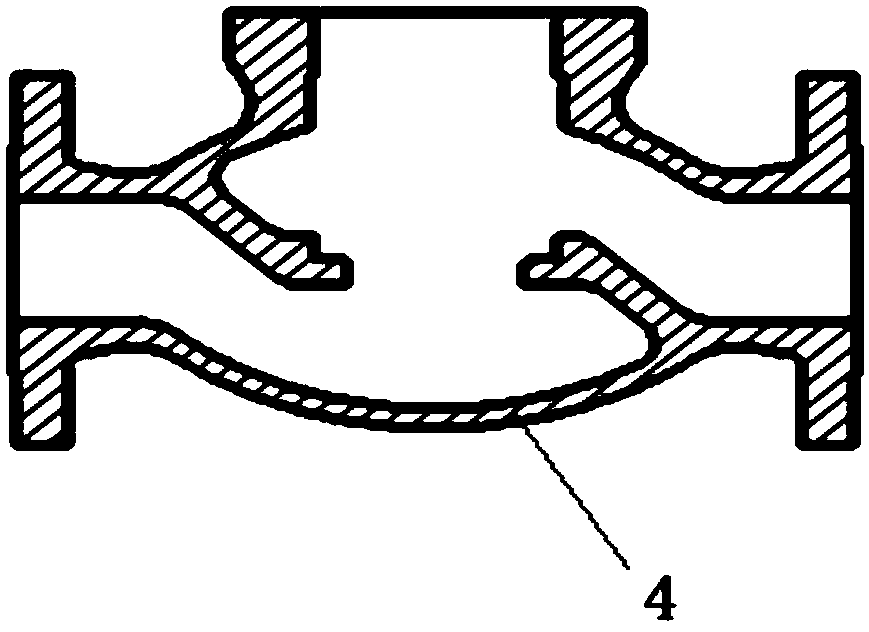

[0034] like figure 1 , 2 As shown, the detachable valve body vent valve disclosed by the present invention includes a valve body, the inlet and outlet ends of the valve body have end flanges 1 for connecting with pipelines, the top of the valve body has a middle flange 2, and the valve body consists of two The symmetrical semi-valve bodies 3 are docked and fixed. A gasket 4 is provided between the two semi-valve bodies 3. The shape of the gasket 4 is adapted to the shape of the contact surface of the two semi-valve bodies 3. Preferably, the gasket 4 The thickness does not exceed 1mm. The two half valve bodies 3 are fixed by the hoops 5 at the two end flanges 1 and the hoops 5 at the middle flange 2 .

[0035] Because there is no fastening force at the bottom of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com