Vision-based trackless electric door running control method, device and system

A trackless electric door, operation control technology, applied in door/window accessories, power control mechanism, wing leaf control mechanism, etc., can solve the problems of destroying the beauty of the ground and the physical structure, low installation efficiency, high installation cost, etc., to achieve artificial Installation cost reduction, installation cost reduction, installation efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

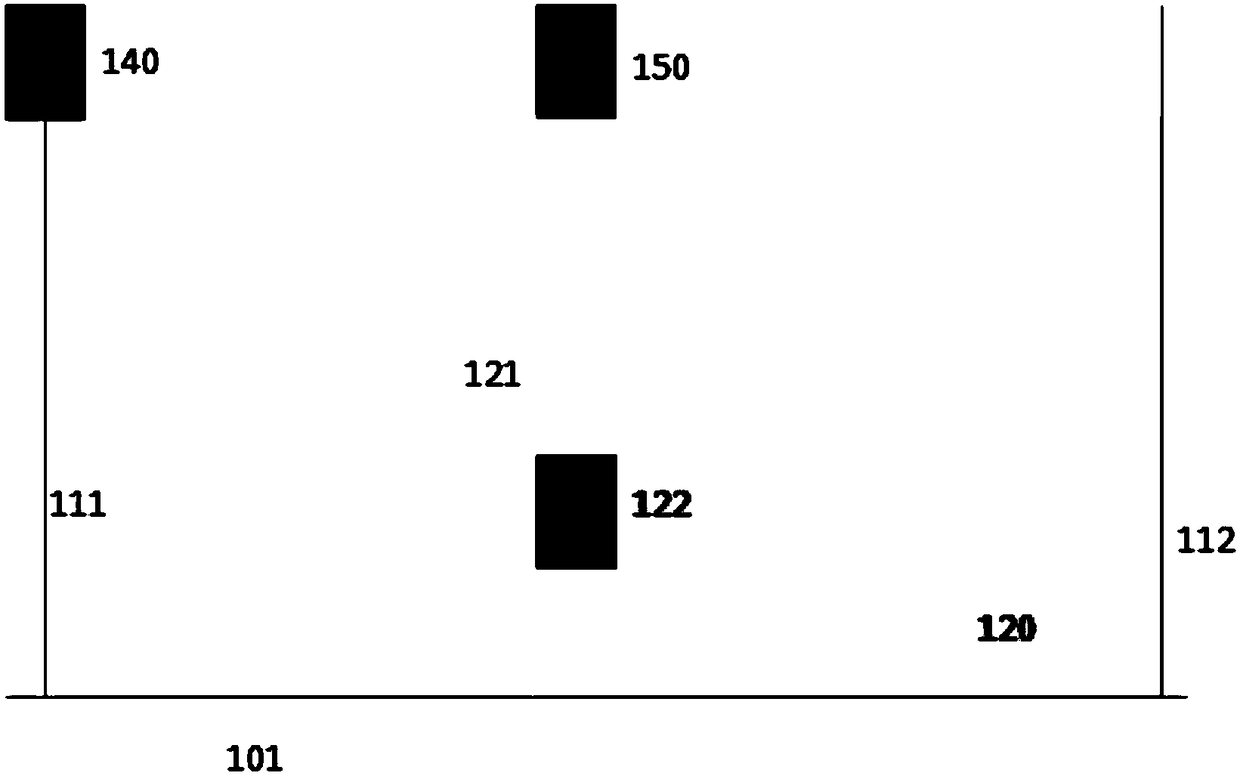

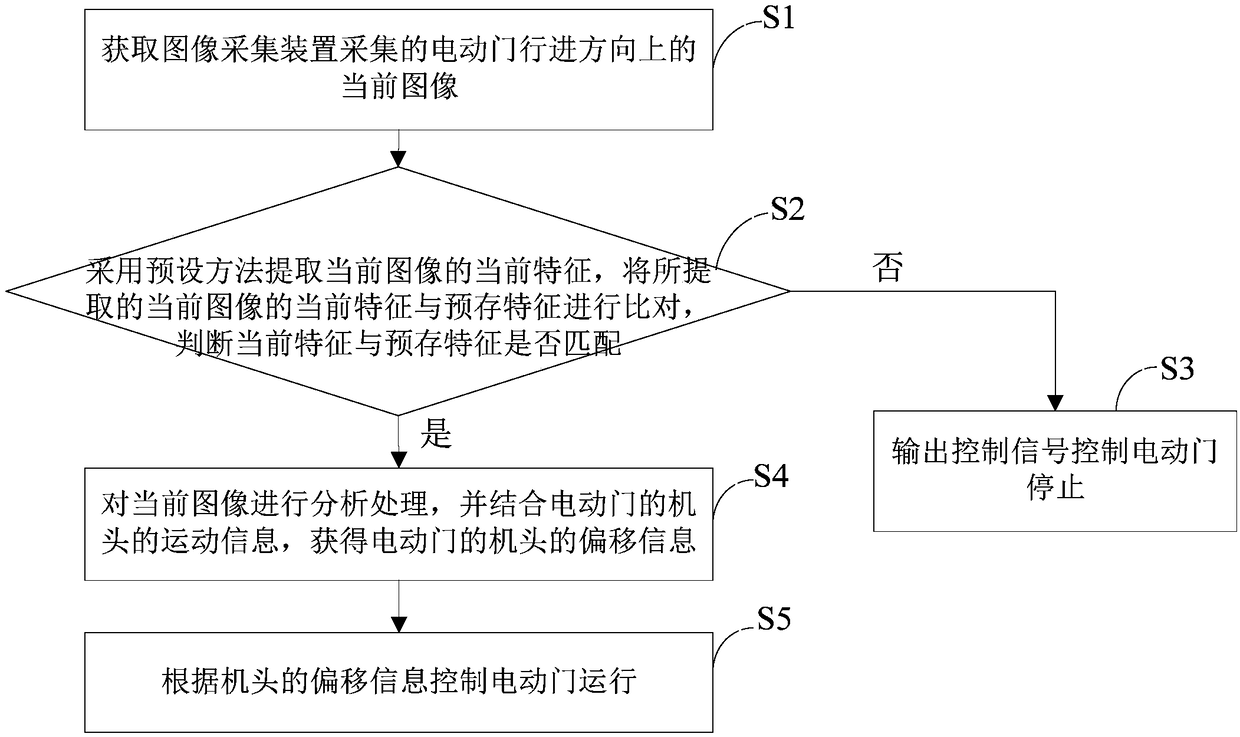

Examples

Embodiment 2

[0080] The second embodiment further includes the following steps on the basis of the first embodiment:

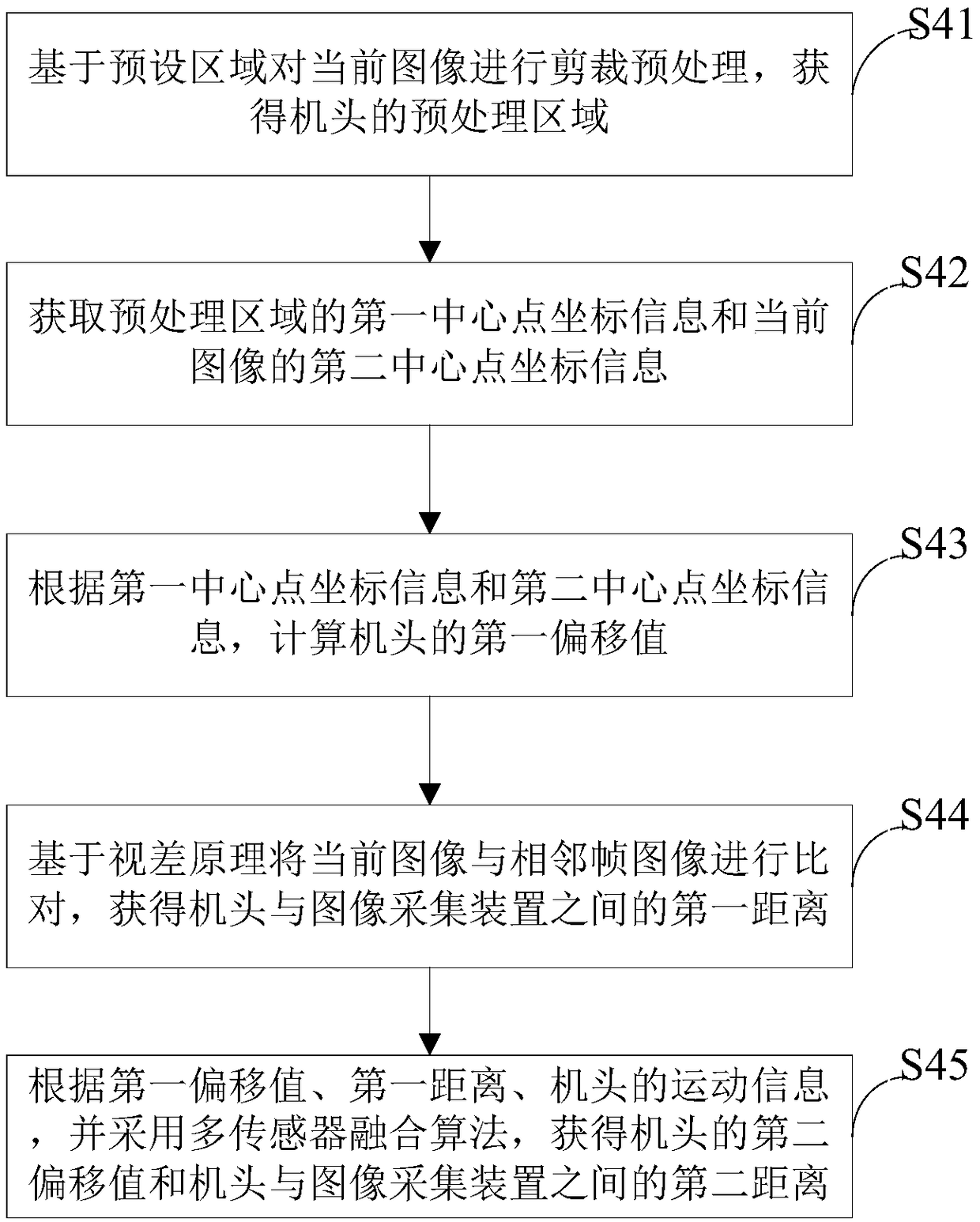

[0081] Specifically, step S4 includes:

[0082] Step S41: Perform crop preprocessing on the current image based on the preset area to obtain the preprocessing area of the handpiece 121.

[0083] Step S42: Obtain the first center point coordinate information of the preprocessing area and the second center point coordinate information of the current image.

[0084] S43: According to the first center point coordinate information and the second center point coordinate information, a first offset value of the computer head 121.

[0085] Take d 1 Represents the first offset value, then the first offset value d 1 It can be obtained in the following ways:

[0086] Specifically, suppose that the abscissa in the first center point coordinate information of the preprocessing area is x1, and the abscissa in the second center point coordinate information of the current image is x2. Then, under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com