Inner side fixed type optical fiber transfer device and operation method thereof

A transfer device, fixed technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of low transfer efficiency, inaccurate transfer, difficult to observe with the naked eye, etc., and achieve the effect of high transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

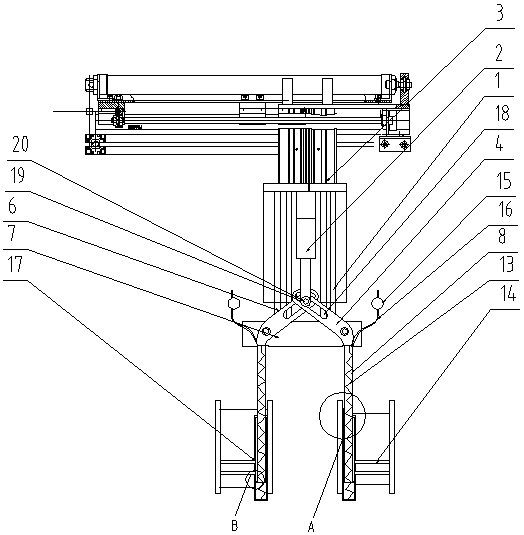

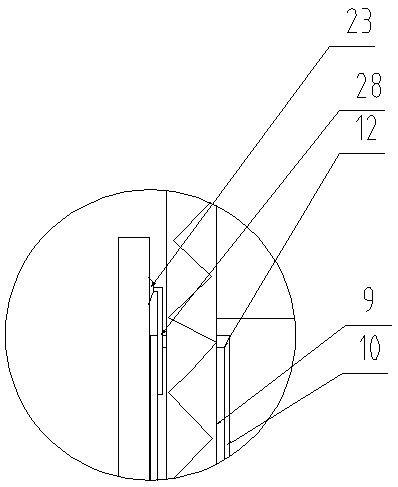

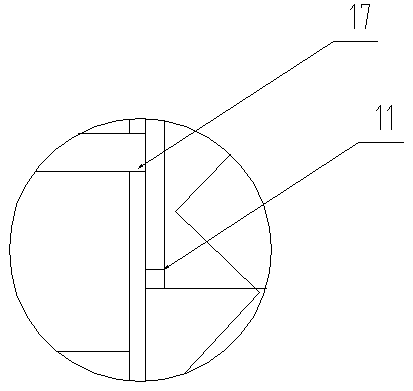

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a kind of inner fixed optical fiber transfer device provided by the present invention includes: lift cylinder 1, telescopic cylinder 2, lift 3 and a pair of oblique arms 4, the top of the lift cylinder is fixed on the lift; the lift cylinder has Lifting rod 6, the end of the lifting rod is equipped with a fixed plate 7, one end of a pair of said oblique arms is respectively hinged on the two ends of the fixed plate, the other end of said oblique arm is equipped with an internal hollow telescopic rod 8, said telescopic rod It includes a hollow inner rod 9 and a hollow outer rod 10 sheathed on the inner rod, the outer rod can slide along the outer wall of the inner rod, the outer end wall of the inner rod has a stopper 11, the inner side of the outer rod A stop ring 12 is provided on the end wall; a spring 13 is provided inside the outer rod, one end of the spring is ...

Embodiment 2

[0040] The invention also discloses an operation method of an optical fiber transfer device, which includes the following steps:

[0041] 1) When the optical fiber transfer device is in the middle of two groups of optical fiber reels, the control unit sends a signal to the elevator, lifting cylinder and telescopic cylinder, so that the elevator and lifting cylinder push the fixed plate down, and the extension arm of the telescopic cylinder is downward Stretch; at this time, the control unit opens the gas flow control valve so that the output pressure P of the gas flow control valve 1 1 ;

[0042] 2) When the sounding shell on the upper part of the telescopic rod is close to the inner wall of the fiber optic reel, the gas in the sounding shell touches the fiber optic reel to make a sound, and the sound sensor collects the sound signal from the sounding shell and sends the sound signal to the control unit; control The unit controls the elevator and the lifting cylinder to stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com