A method of controlling the voltage of the electrolytic cell and the position of the clamping frame

A clamping frame and tank voltage technology, which is applied in the field of aluminum electrolysis, can solve the problems of complex clamping frame, low efficiency, unreasonable control method of tank voltage and clamping frame position, and achieve unmanned operation and control of tank voltage The position of the clamping frame is easy and accurate, and the effect of improving the level of mechanization and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

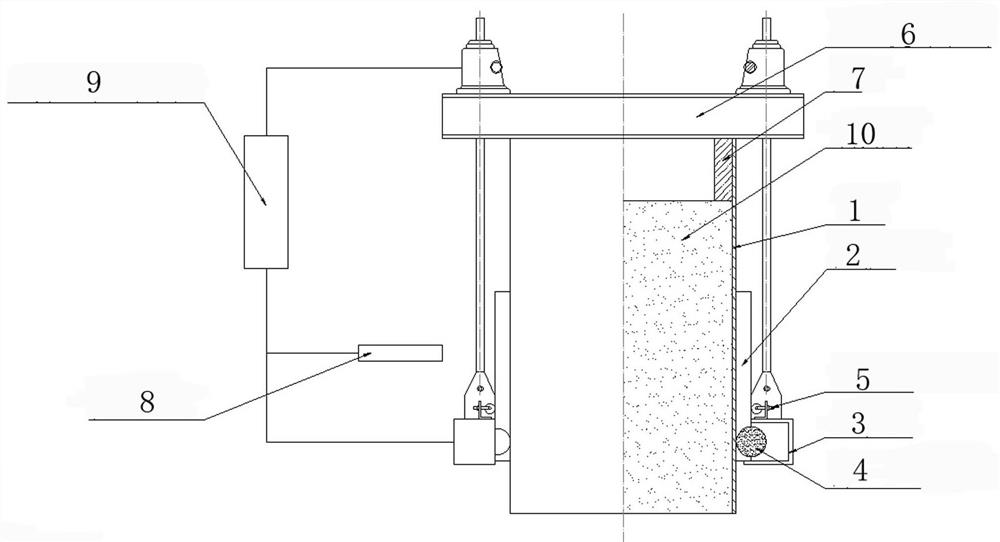

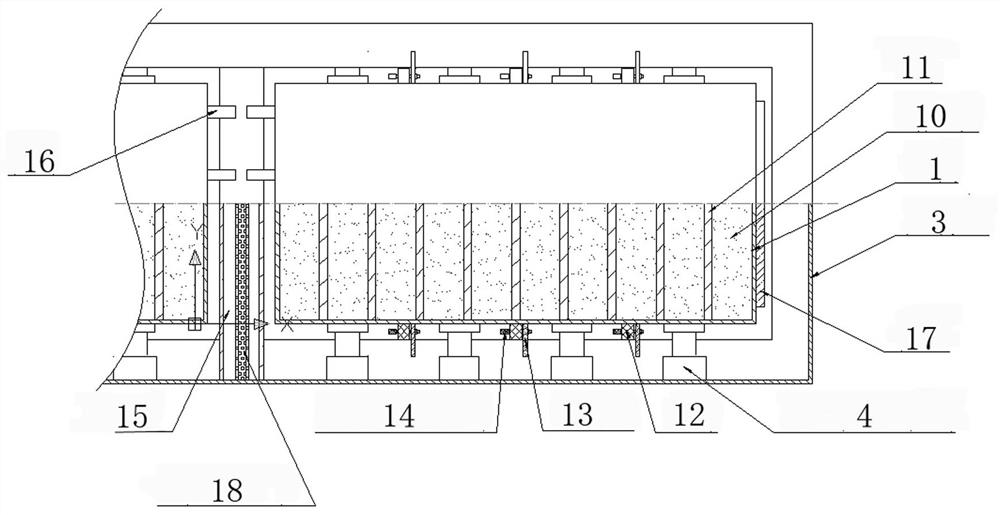

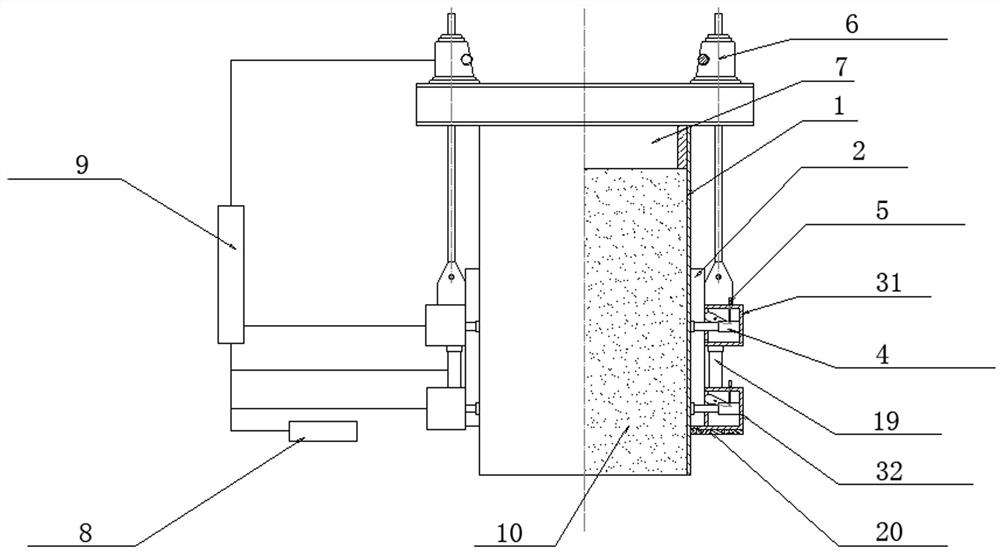

[0052] See figure 1 and 2 At least one aluminum cylinder anode is arranged in the clamping frame, the aluminum cylinder anode includes an aluminum cylinder 1, a plurality of conductors 11 in contact with the aluminum cylinder are arranged in the aluminum cylinder, at least one inner cylinder 7 is arranged in the aluminum cylinder at the top of the conductor, The clamping frame 3 is connected with at least one anode lifting mechanism 6 for adjusting the cell voltage, and secondly, several first pressing mechanisms 4 which are in contact with the built-in conductor aluminum cylinder are arranged on the clamping frame, and at least A detection unit 8, the detection unit, the first pressing mechanism and the anode lifting mechanism are all connected with the control system 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com