Statistical Process Control Method for Zero Excessive Particle Count in Clean Room

A statistical process control and particle number technology, applied in the registration/indication manufacturing process, registration/indication quality control system, calculation, etc., can solve problems such as unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

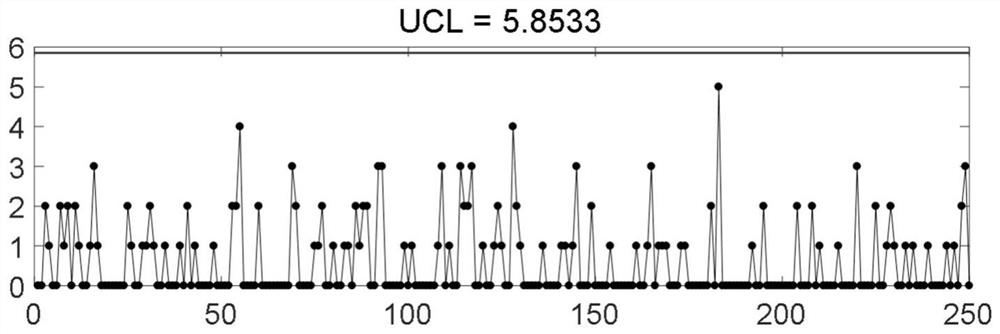

[0053] The present invention will be further described below by taking the number of particles collected in a clean room of an integrated circuit manufacturing company as an example in conjunction with the accompanying drawings.

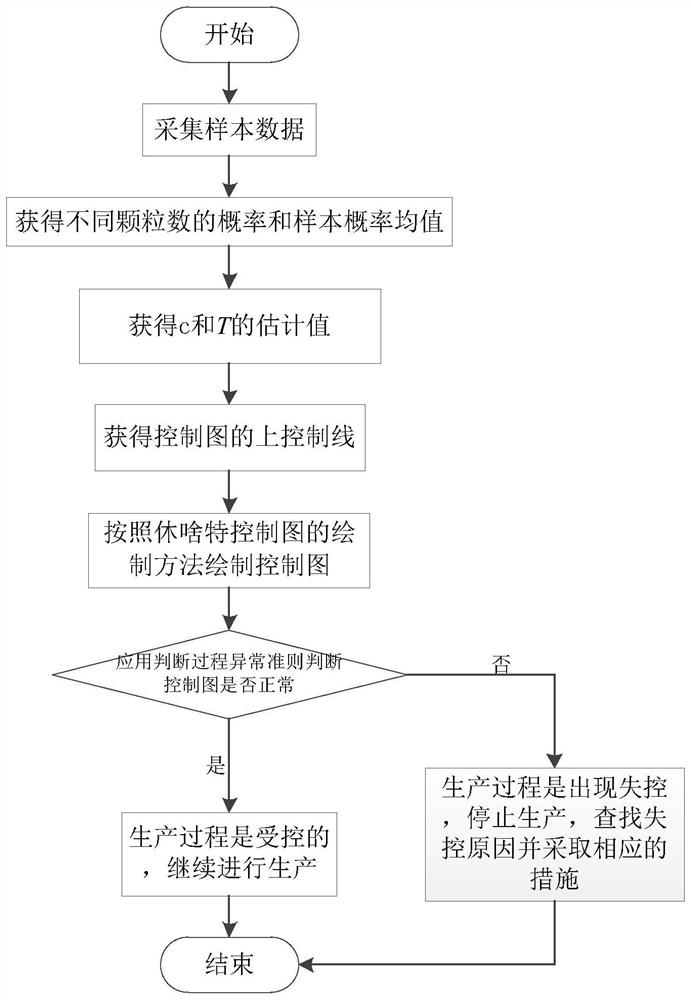

[0054] refer to figure 1 , the implementation steps of this example are as follows:

[0055] Step 1: Collect a sample.

[0056] Using a Lasair II-100 particle counter, in a clean room with a cleanliness of 100, the number of particles with a particle diameter greater than 0.5um is collected, and the data is collected once per minute. After collecting 250 samples continuously, 90 zero data are obtained, and the sample data are shown in Table 1.

[0057] Table 1 Sample data with zero excess particle count

[0058]

[0059]

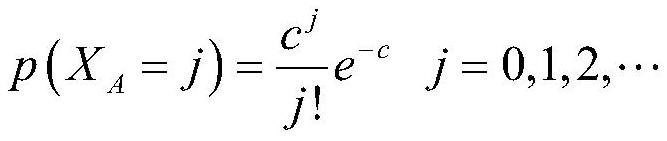

[0060] Step 2: Obtain the sample data according to step (1), and obtain the sample probability p with the number of particles m m and the sample probability mean

[0061] 2a) Perform statistics on the sample data in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com