A kind of multi-layer composite semi-transparent mirror and vehicle head-up display system

A multi-layer composite material and semi-reflective mirror technology, applied in the optical field, can solve the problems of tediousness, low output efficiency, high manufacturing cost, etc., and achieve the effects of reducing manufacturing costs, resisting surface scratches, and enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

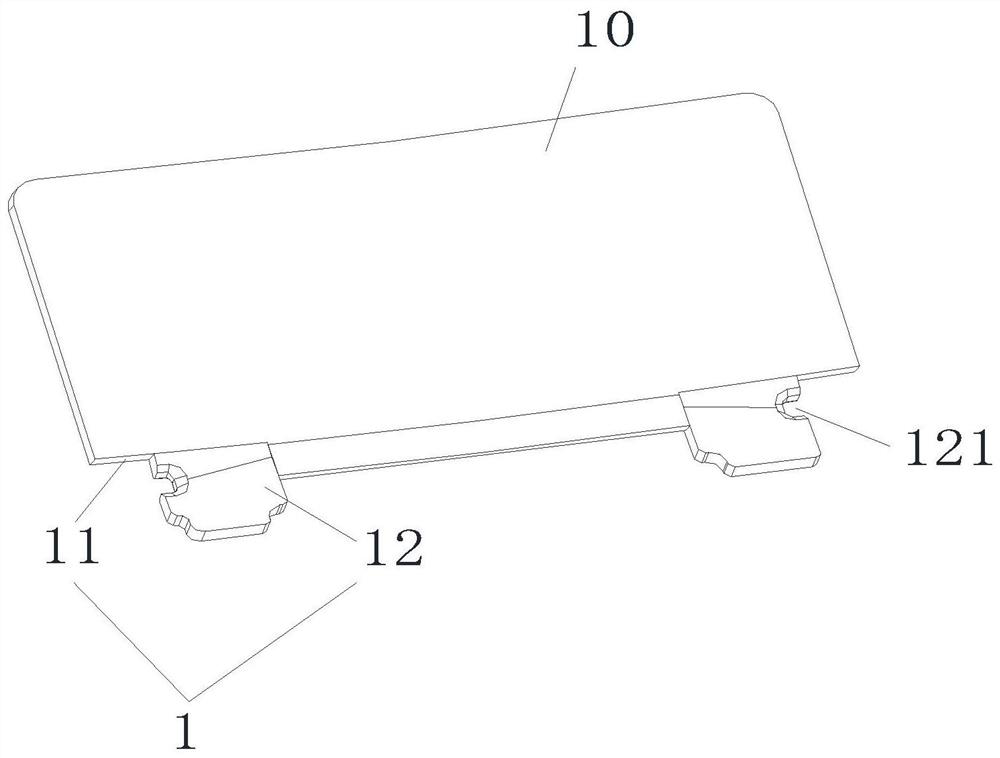

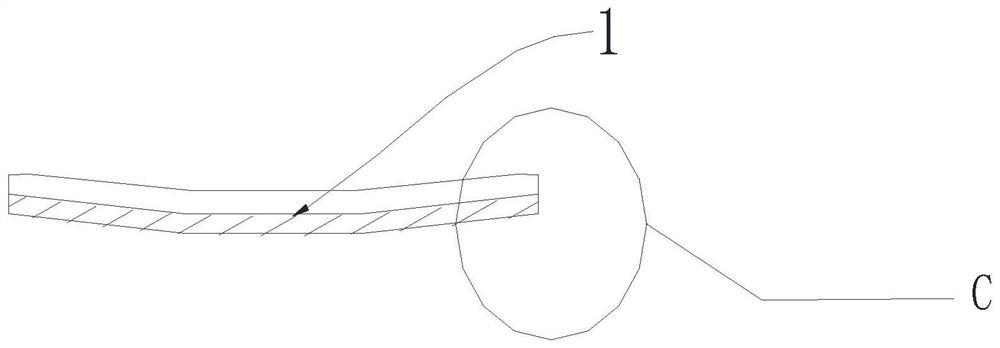

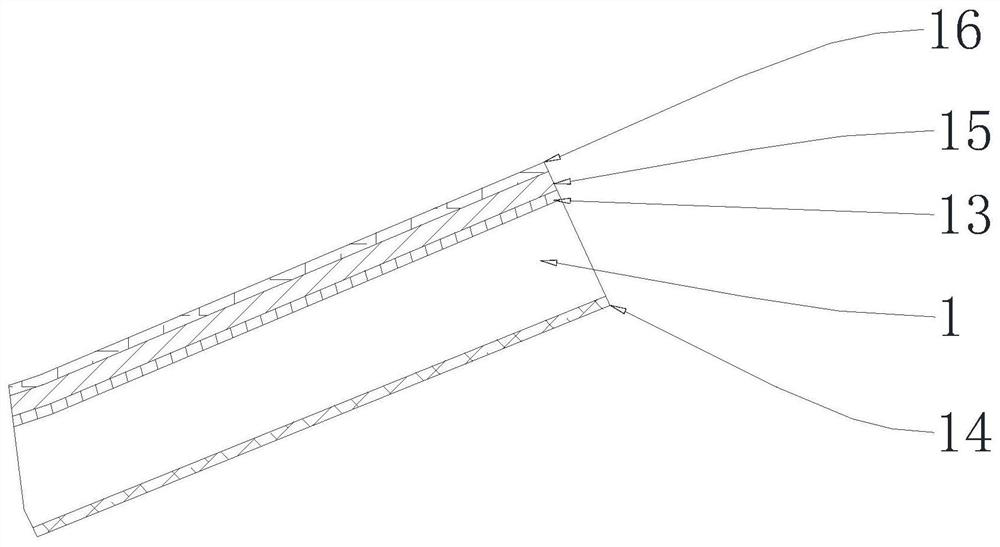

[0031] see Figure 1 to Figure 6 As shown, a kind of multi-layer composite material half mirror 10 of the present invention comprises the transparent plastic substrate 1 of the half mirror, and the transparent plastic substrate 1 of the half mirror is composed of an optical imaging surface 11 The optical imaging surface 11 and the assembly lug 12 are made of thermoplastic engineering plastics, and the upper surface of the optical imaging surface 11 is provided with an adhesive film layer 13. Then the film layer 13 is made of trititanium pentoxide, and the lower surface of the optical imaging surface 11 is provided with an anti-reflection film layer 14, and the anti-reflection film layer 14 is made of silicon dioxide. There is a silicon-aluminum mixture reflection film layer 15, and a waterproof film layer 16 is arranged on the silicon-aluminum mixture reflection film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com