Textile fabric leveling device

A leveling device and technology for textile fabrics, applied in textiles and papermaking, fabric finishing guides/expanders, fabric surface trimming, etc., can solve the problems of uneven fabric wrinkles, affecting the quality of garments, and poor leveling effects. Wrinkles, not easy to separate, and the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

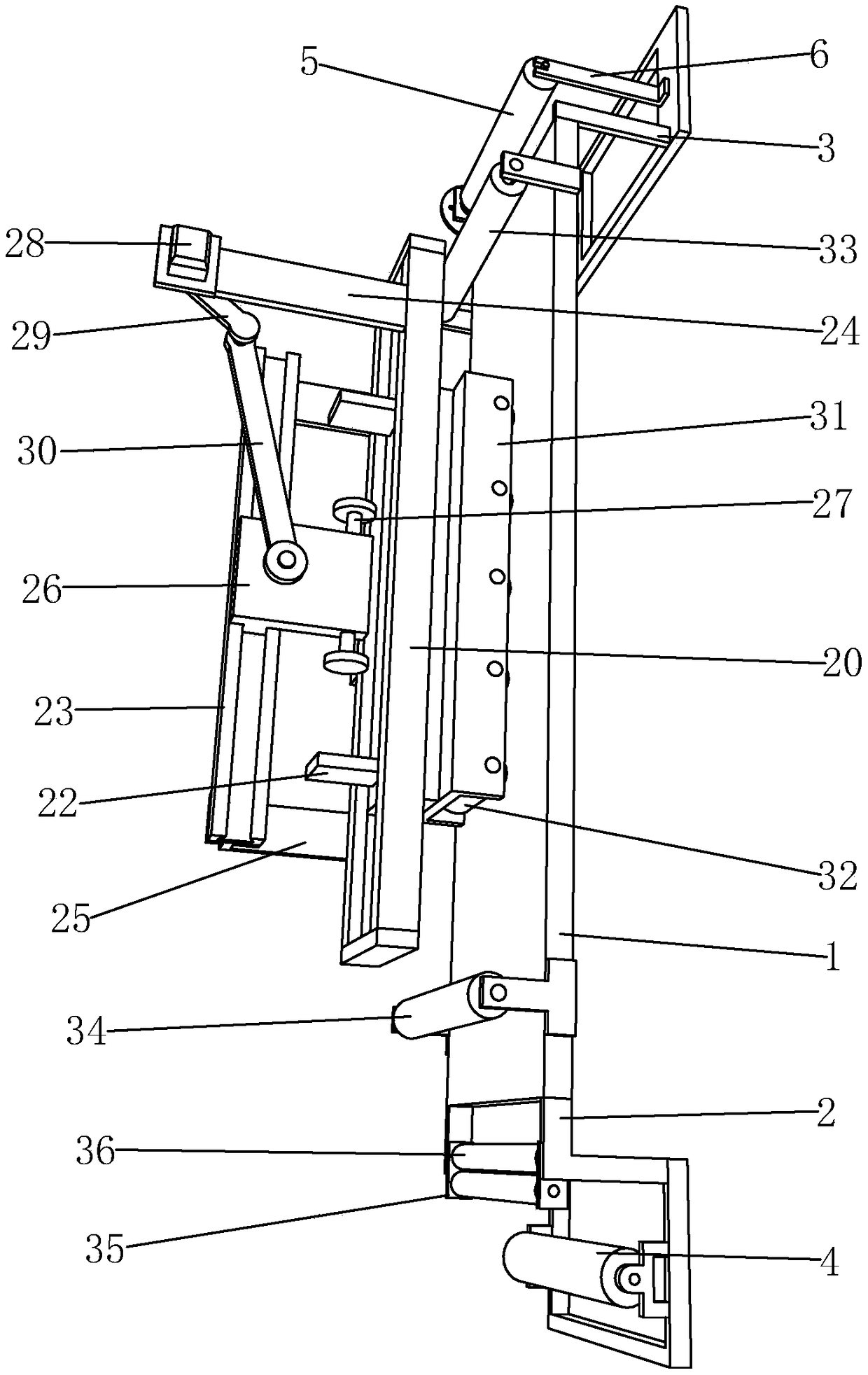

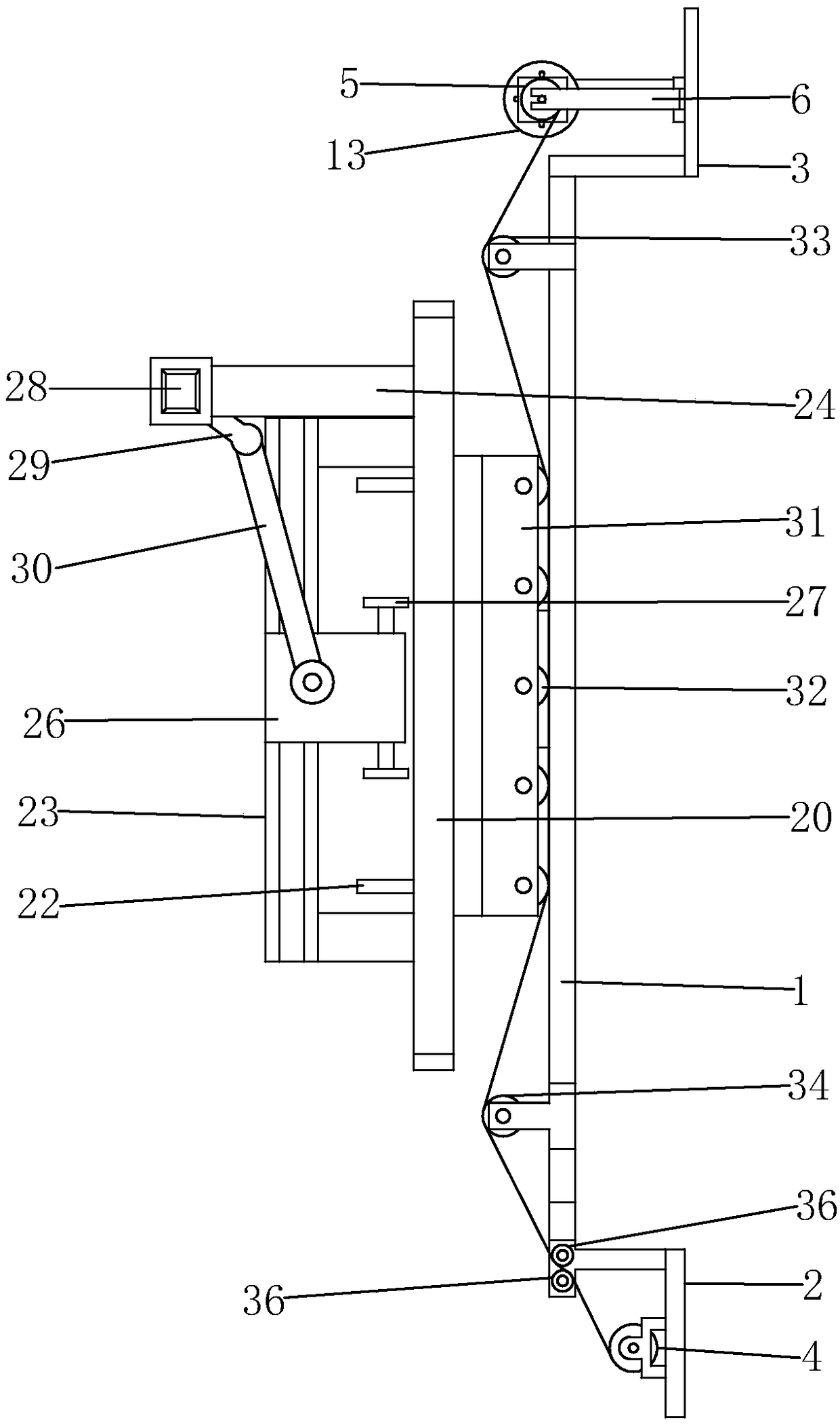

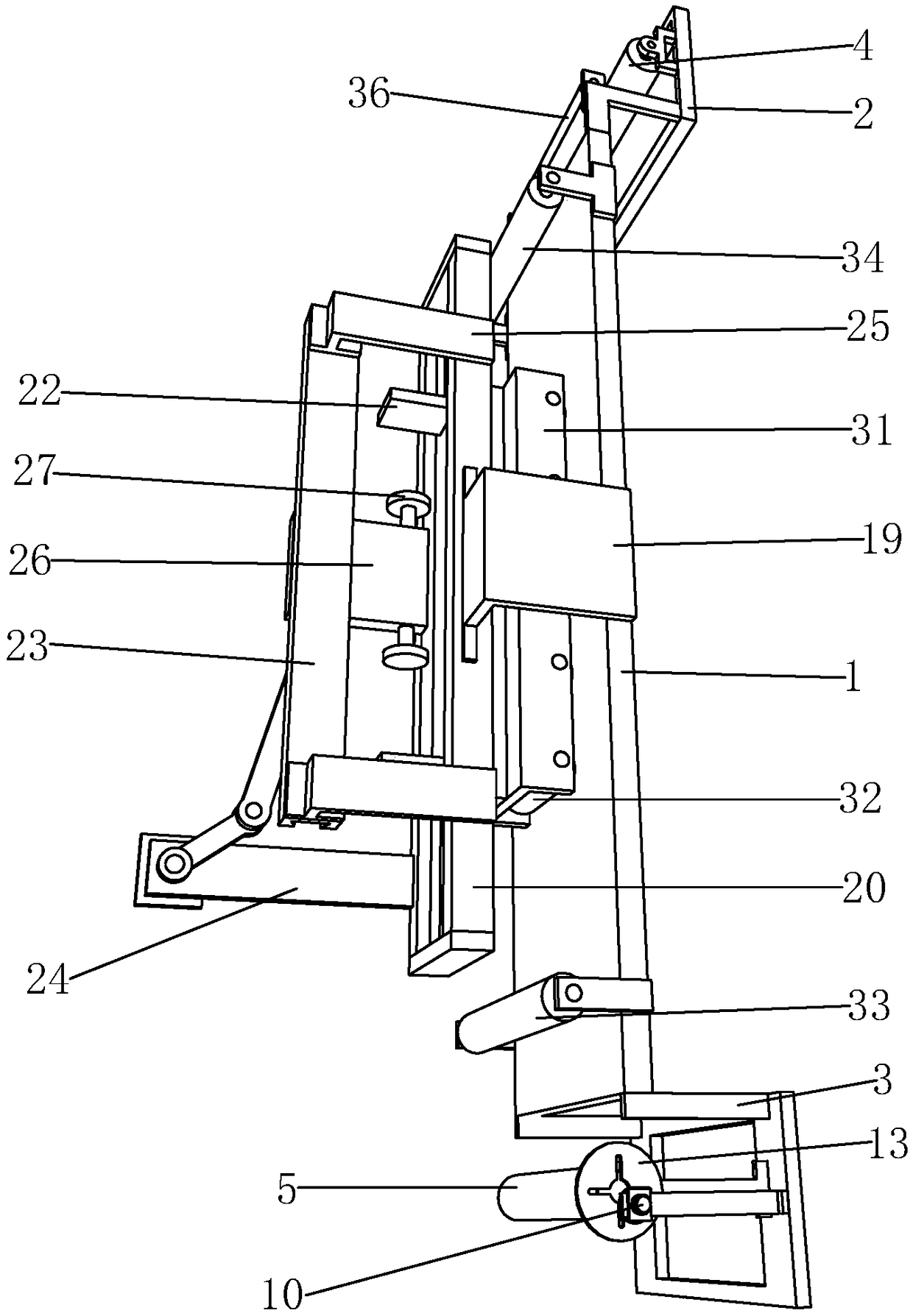

[0026] Such as Figure 1 to Figure 7 As shown, it is a kind of textile fabric leveling device of the present invention, comprising a leveling plate 1, the two sides of the leveling plate 1 are respectively provided with a fixed bracket 2 and a support frame 3, and the fixed bracket 2 is provided with a cloth releasing roller 4, and a support frame 3 Cloth receiving roller 5 is arranged on it, bracket 6, support plate 7 and vertical plate 8 are respectively arranged on support frame 3, turntable 9 is connected with rotation on support plate 7, and cloth take-up roller 5 is arranged between turntable 9 and bracket 6. In between, the vertical plate 8 is provided with a cloth receiving motor 10, which is connected with a driving disc 11, and the driving disc 11 is eccentrically provided with a fixed pin 12, and the rotating disc 9 is provided with a driven disc 13, and the center of the driven disc 13 A through hole 14 is provided, and a bar-shaped limiting groove 15 is distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com