Anti-explosion device and method for top of switch cabinet

An explosion-proof device and switchgear technology, applied in switchgear, switchgear settings, electrical components, etc., can solve the problems of air pressure not being released in time, slow uniform speed, and increase in air pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

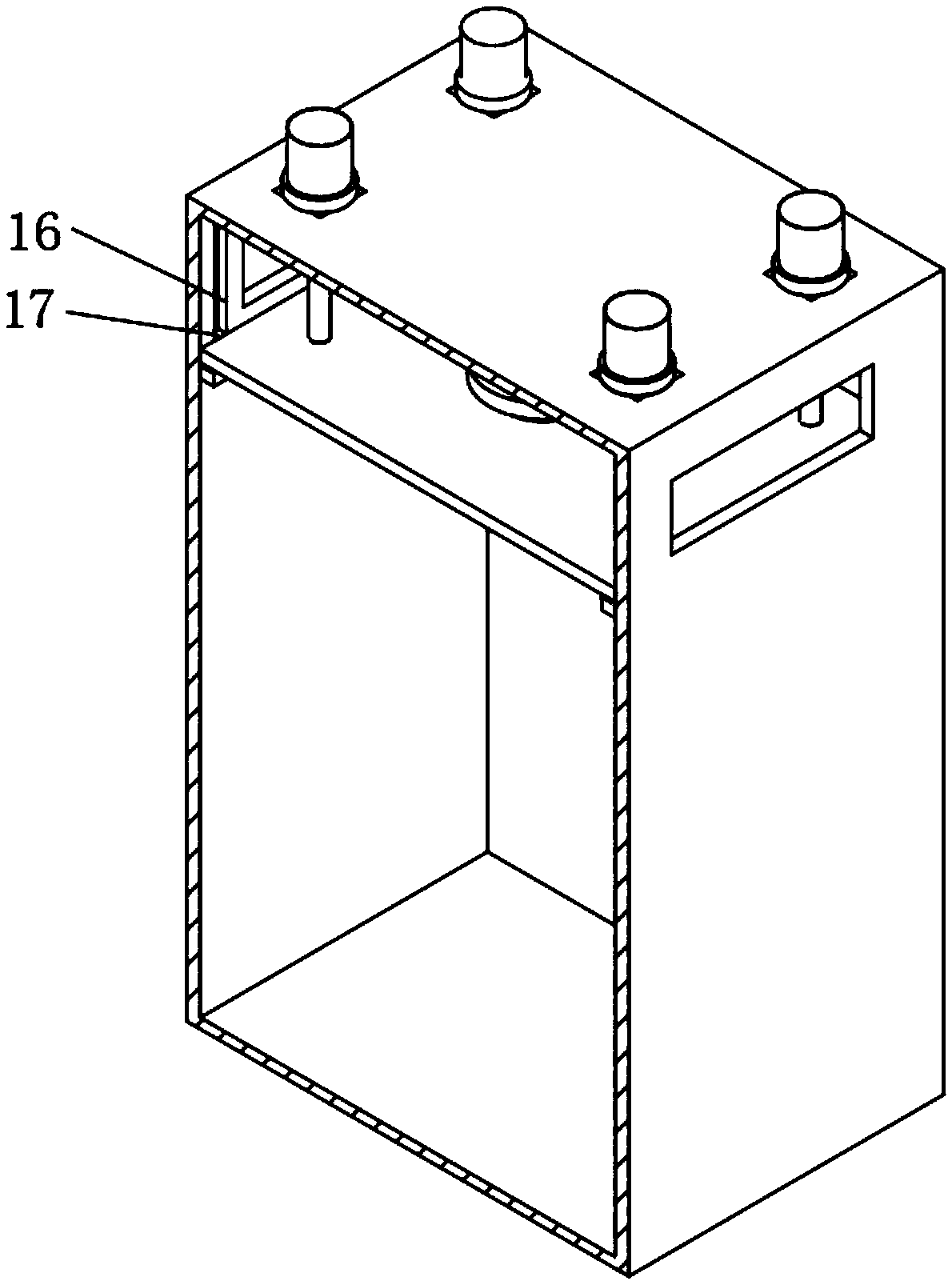

[0021] refer to Figure 1 to Figure 4 According to the present invention, an explosion-proof device at the top of a switch cabinet comprises: a cabinet body 1, and a partition plate 3 that can slide along the height direction of the cabinet body 1 is arranged in the cabinet body 1, and the partition board 3 divides the cabinet body 1 into upper space and The lower space, wherein the lower space is used to install various electrical components, and an explosion-proof membrane 8 for releasing the inflation gas in the lower space is installed on the partition plate 3 . Preferably, a threaded through hole 6 is formed in the middle of the partition 3, and a threaded ring 7 is threaded in the threaded through hole 6, and an explosion-proof membrane 8 is fixedly installed in the threaded ring 7, so that after the explosion-proof membrane 8 bursts, it can Quick change....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com