Suppression Method of Airflow Disturbance Error in Non-contact Measurement of High Temperature Deformation

A non-contact measurement and airflow disturbance technology, applied in the field of measurement, can solve the problems of displacement field distortion, noise reduction effect is not as good as mean filtering, can not solve the effect of airflow field, etc., to achieve the effect of eliminating random fluctuations and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0044] The invention provides a method for suppressing airflow disturbance errors in non-contact measurement of high-temperature deformation.

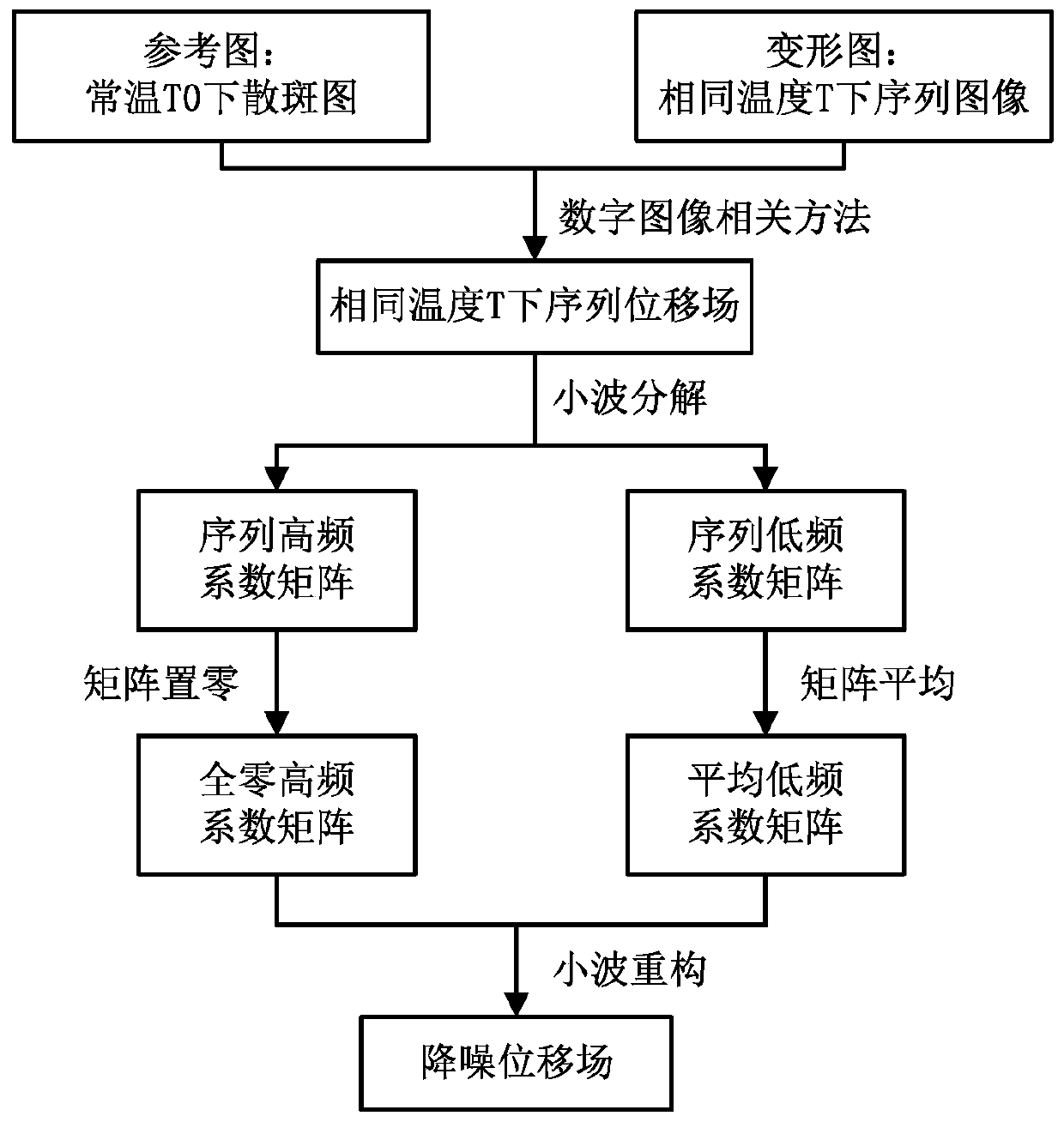

[0045] Such as figure 1 As shown, the method includes the following steps:

[0046] S1: Build a non-contact deformation measurement system:

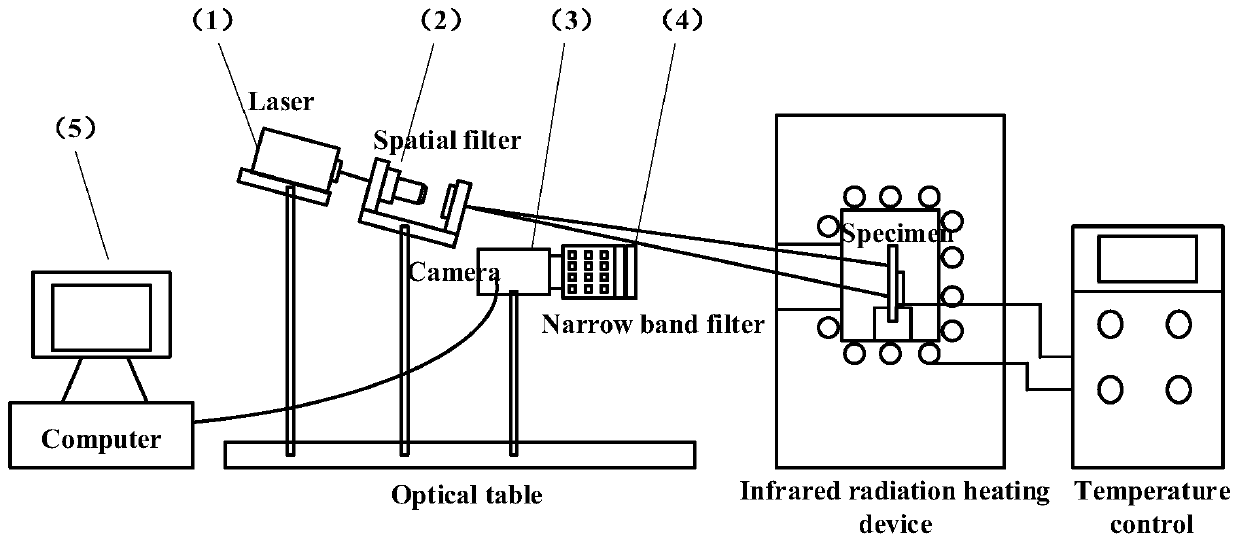

[0047] Such as figure 2As shown, the system includes: a single longitudinal mode laser 1, a spatial filter 2, an industrial CCD camera 3, a narrowband filter 4 and an image acquisition system 5, the laser light generated by the single longitudinal mode laser 1 passes through the spatial filter 2, and undergoes spatial filtering The beam expander 2 uniformly irradiates the surface of the sample to form a speckle field, and the industrial CCD camera 3 collects the speckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com