Casing collar locator for coiled tubing

A casing coupling and locator technology, applied in casing, drill pipe, drilling equipment and other directions, can solve the problems of fracturing pipe stuck in series, inaccurate positioning, production accidents, etc., and achieves easy disassembly and maintenance, and large space. , the effect of simple tool structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

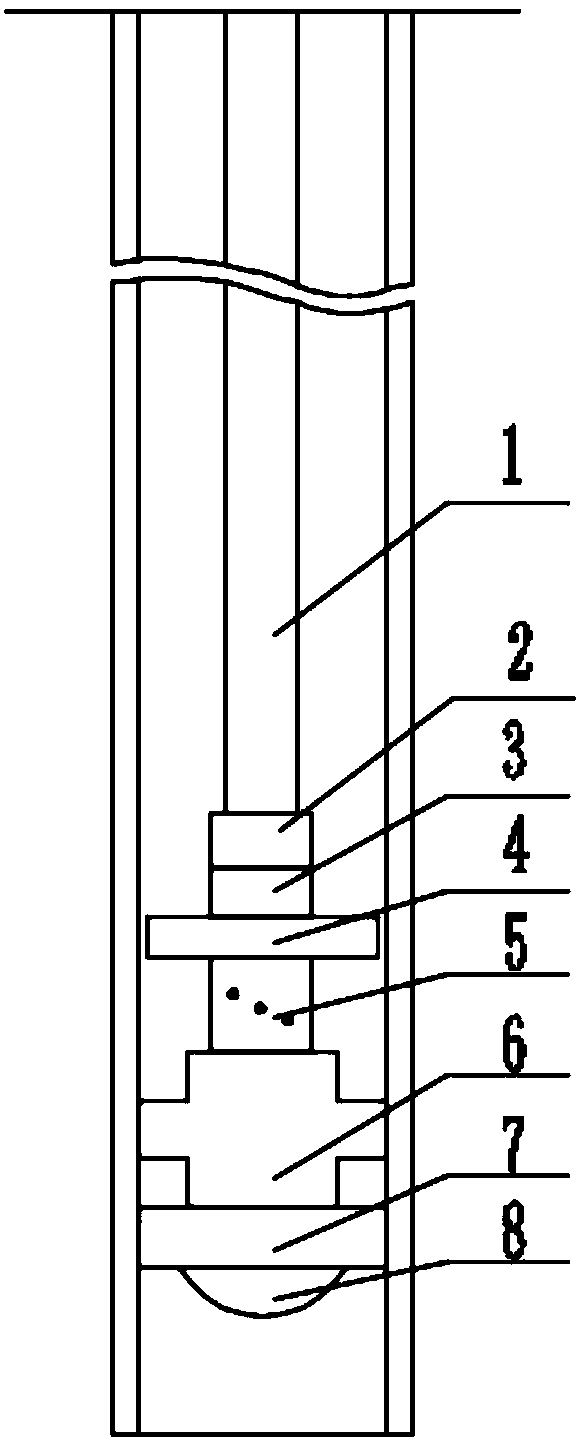

[0016] Such as figure 1 As shown, the conventional coiled tubing sandblasting and perforating staged fracturing string mainly includes coiled tubing joints 2, throwing hands 3, centralizers 4, perforating guns 5, packers 6, casing collar positioners 7, Guide head 8. During the fracturing process, a large amount of fracturing sand will sink in the wellbore. When the conventional casing collar positioner moves up and down with the coiled tubing string in the casing, the groove is not sealed and is in an open state. The fracturing sand It will enter the groove with the liquid and even fill the groove, which will affect the elastic change of the shrapnel and then affect the stroke of the positioning block in the groove, and even the positioning block cannot be recovered, causing the pipe string to be stuck at the casing collar, resulting in ACCIDE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com