Metal stable driving type cutting mechanism

A cutting mechanism and driving technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, clamping, etc., can solve the problems of the cutting knife not being able to float and expand, the range of use, and the limitation of flexibility, so as to achieve smooth friction and avoid friction , to achieve the effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

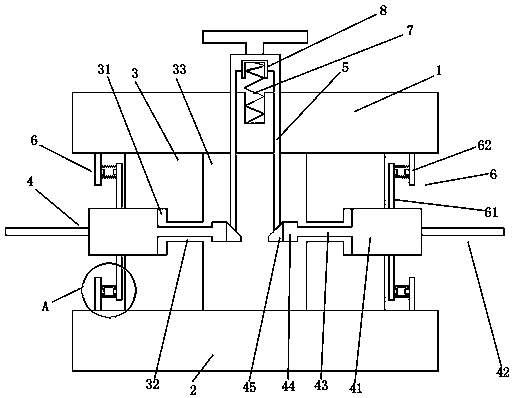

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

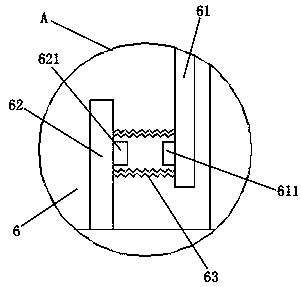

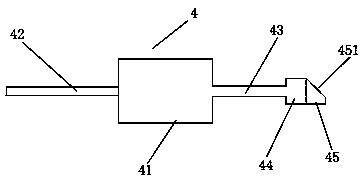

[0020] Such as Figures 1 to 4 As shown, a metal smooth driving cutting mechanism includes an upper splint 1, a lower splint 2, a connecting ring 3, a driving column 5, a cutting assembly 4, a pressing mechanism 6, a transitional elastic body 7, and a wear-resistant sleeve 8; The upper splint 1 and the lower splint 2 are respectively arranged in parallel up and down; the connecting ring 3 is installed between the upper splint 1 and the lower splint 2; the inside of the connecting ring 3 is provided with a drive cavity 33; the connecting ring 3 A plurality of telescopic slots 31 are uniformly arranged around the body; the cutting assembly 4 includes a cutting knife 42, a telescopic block 41, and a drive rod 43; a telescopic block 41 is installed radially in the telescopic slot 31 of the connecting ring 3 The outside of the telescopic block 41 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com