Motor positioning and mounting structure, motor and household appliances

A technology for positioning installation and installation parts, which is applied in the directions of electromechanical devices, electrical components, and electric components, etc., which can solve the problems of difficulty in aligning screws with threaded holes, easy to scratch the ends of threaded holes, and inaccurate installation positions, and achieve a solution structure. Appearance defects, quick and accurate alignment, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

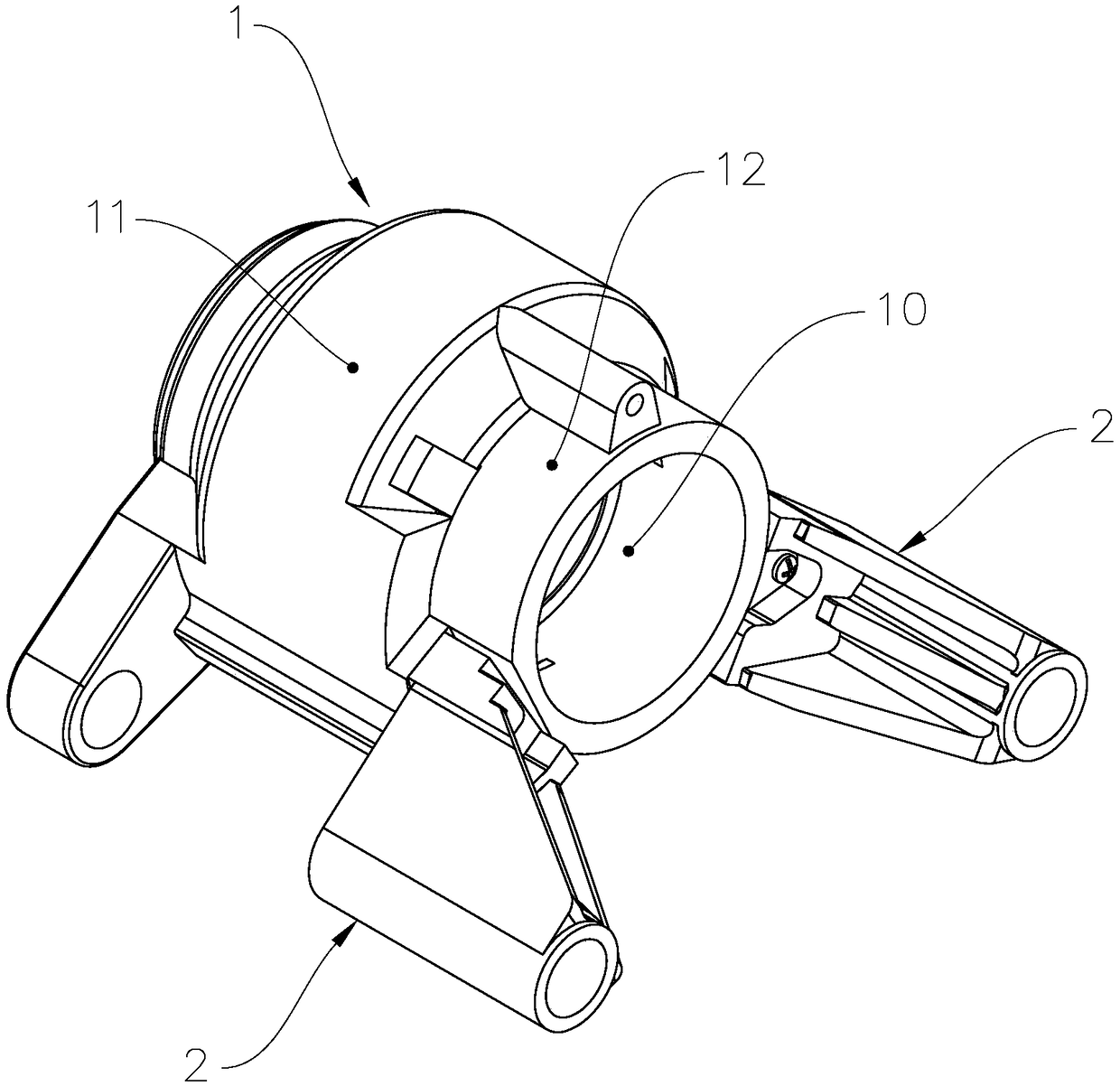

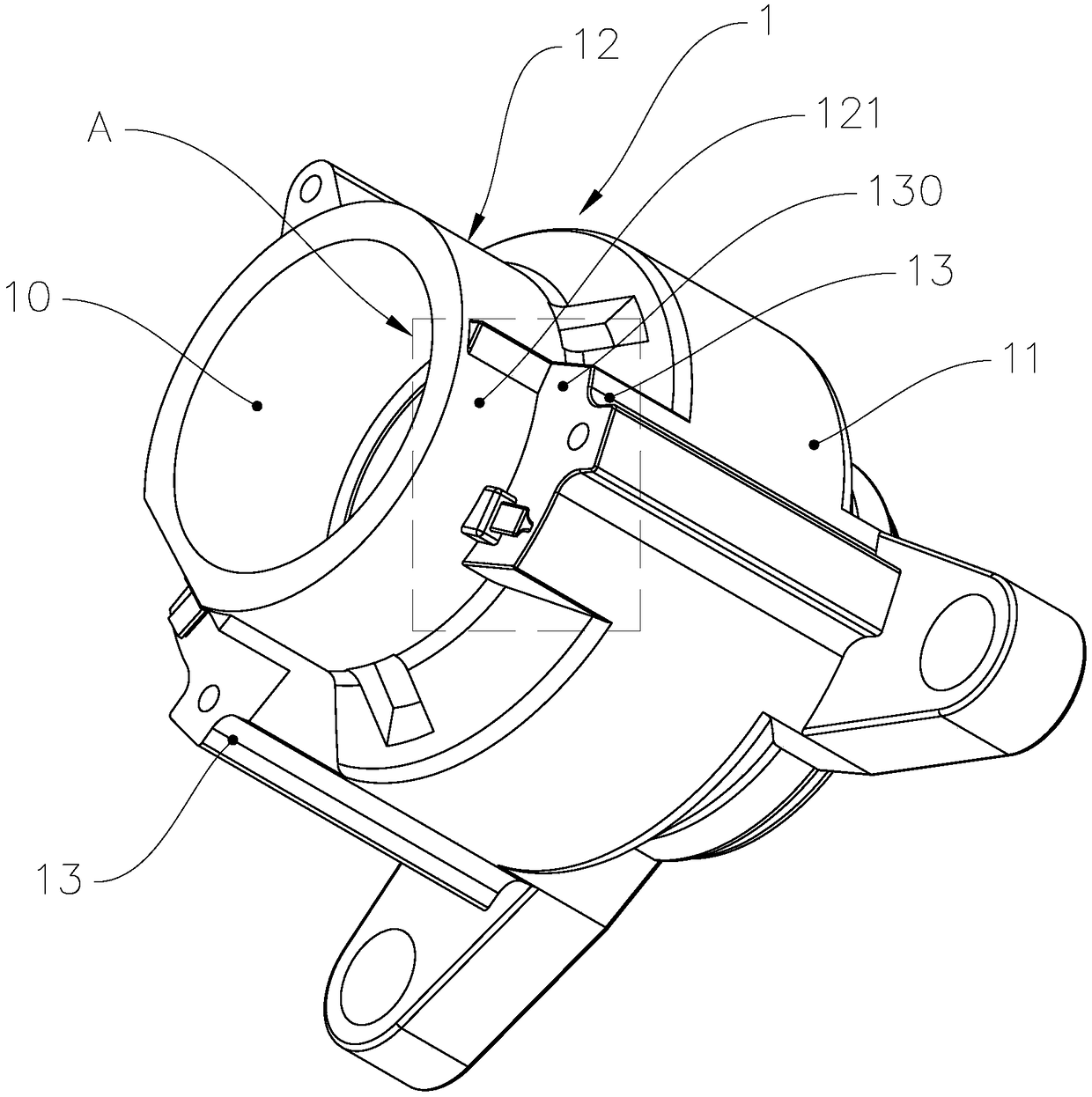

[0040] see figure 1 , figure 1 It is a structural diagram of the first embodiment of the motor positioning and installation structure of the present invention. The motor includes a motor positioning installation structure, the motor positioning installation structure includes a motor casing 1 and two brackets 2 detachably mounted on the motor casing 1, the bracket 2 has a hole column 21 ( Figure 4 shown), the household appliance in this implementation is a washing machine, and the electrical appliance housing is the washing machine housing of the washing machine, and the second bolt passes through the second through hole of the hole column 21 and is locked with the washing machine housing. Since the main invention of the washing machine and the motor of the present invention lies in the positioning and installation structure of the motor, only the positioning and installation structure of the motor will be described in detail.

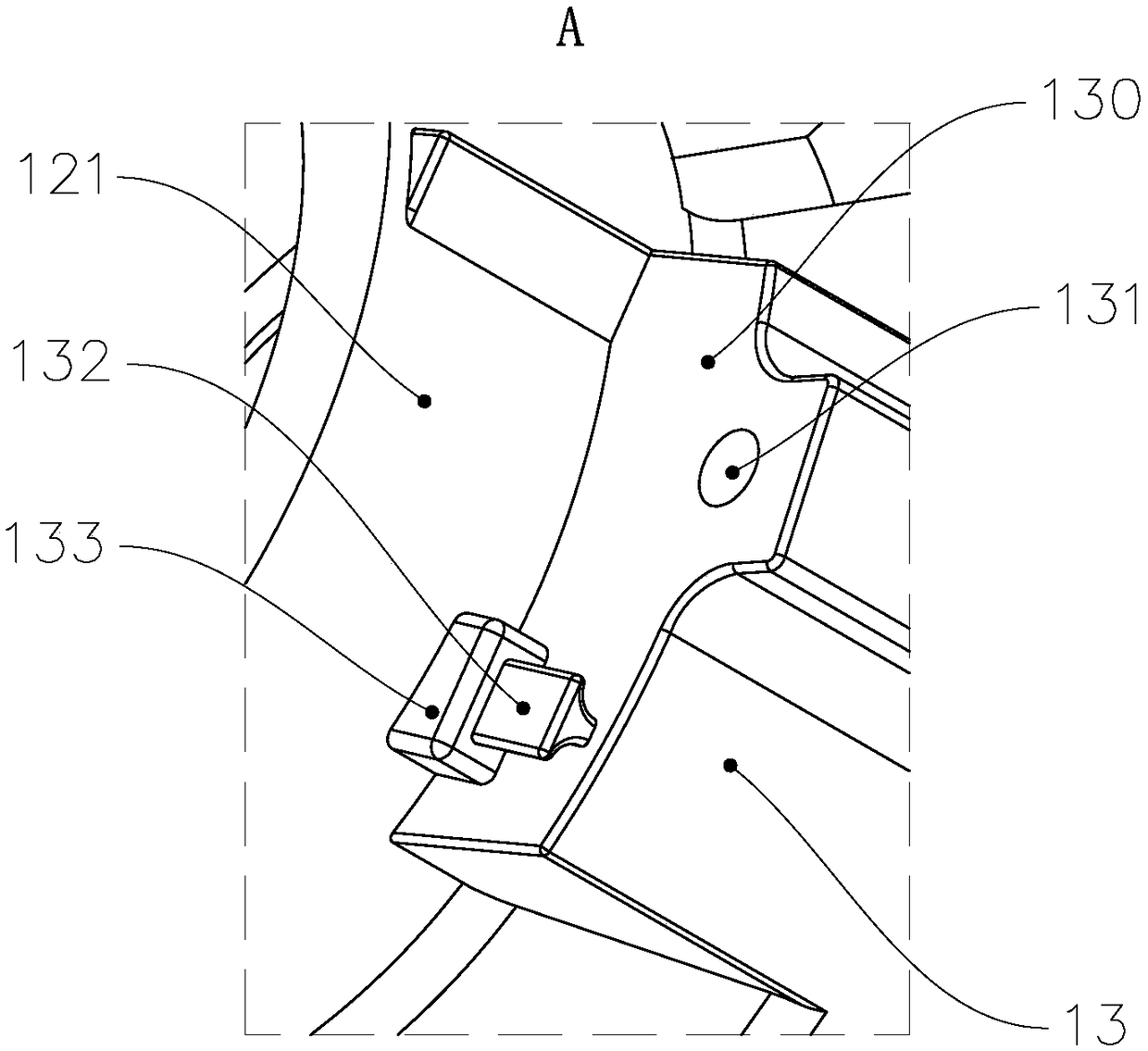

[0041] to combine figure 1 and figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com