Arch frame positioning system and method based on arch frame installation machine for tunnel construction

An arch installation machine and tunnel construction technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of poor automatic positioning function, instability of the initial support structure, and difficulty in accurately guaranteeing assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in combination with specific embodiments.

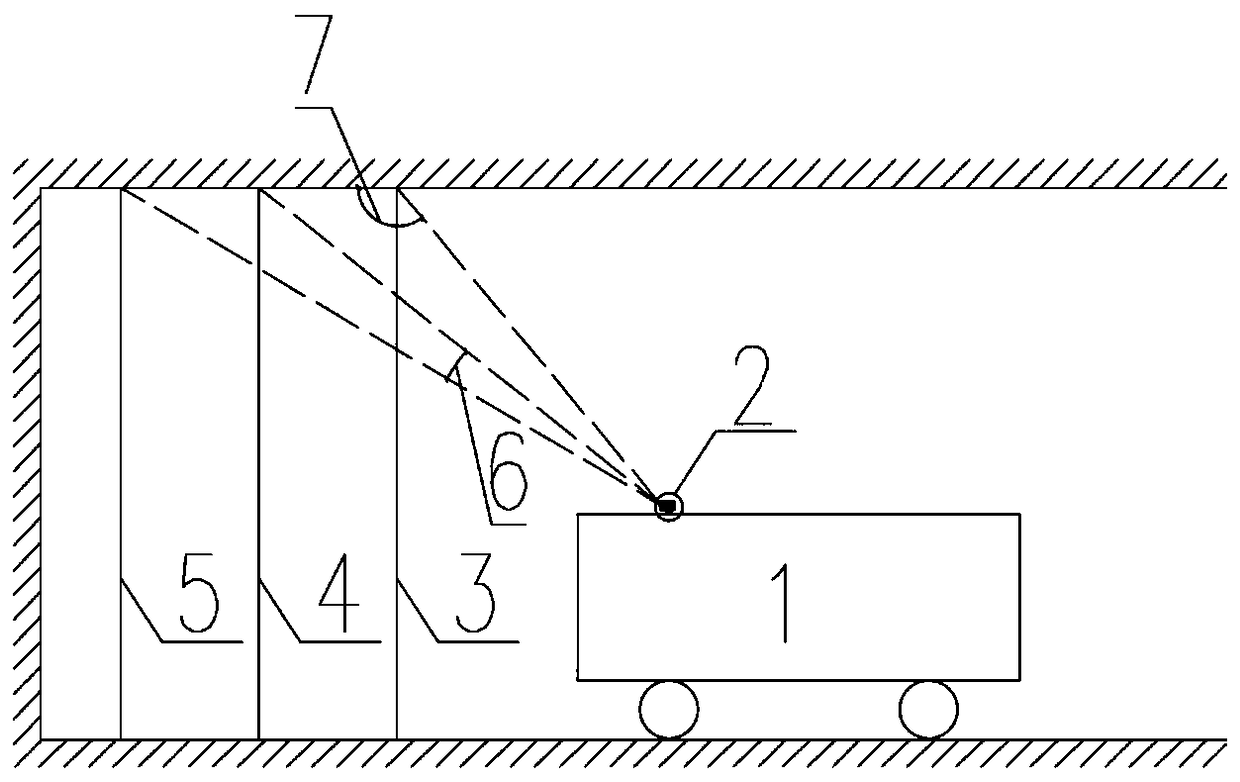

[0038] The invention relates to an arch positioning system based on an arch installation machine for tunnel construction, which can realize the accurate positioning of the longitudinal spacing of the arch and the positions of the circumferential joints. The system includes:

[0039] 1. The laser rangefinder 2 is installed on the outside of the arch installation machine 1 and can rotate with multiple degrees of freedom, and is used to measure the distance between the laser source point and the target point on the two rows of arches that have been assembled.

[0040] The laser range finder 2 involved in the present invention is equipped with several angle controllers on the basis of the existing laser range finder equipment to realize the multi-degree-of-freedom rotation function.

[0041] 2. The central controller is located in the operating room of the arch installation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com