Graphene airgel/polyurethane composite anticorrosion and waterproof coating and its preparation method and application

A graphene aerogel, waterproof coating technology, applied in the direction of polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problem of not resistant to strong polar solvents and strong acid-base media, graphene sheets or film agglomeration , affecting the performance of composite materials, etc., to achieve the effects of low preparation cost, high strength, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

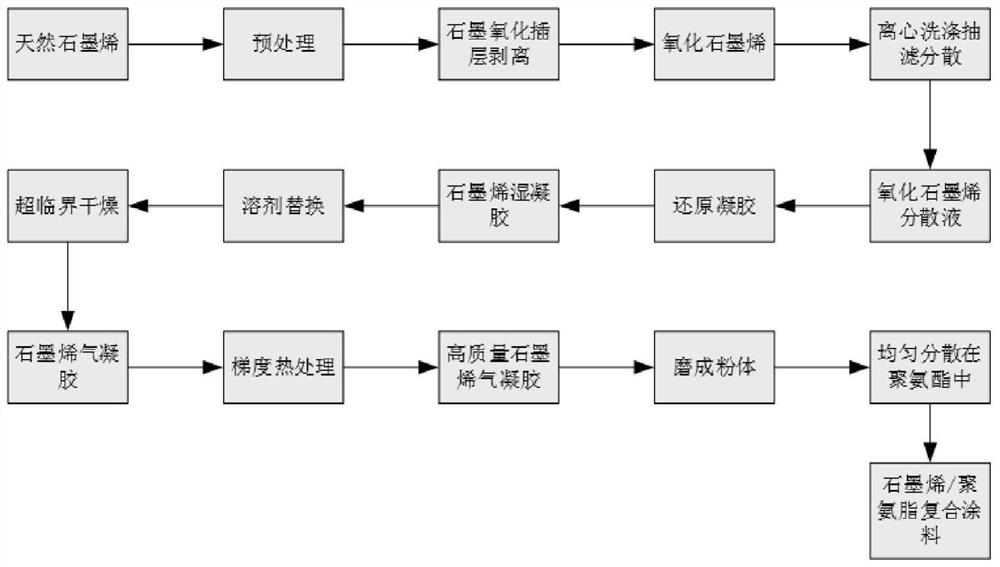

Method used

Image

Examples

Embodiment 1

[0033] (1) adopt hummer method to carry out oxidation intercalation exfoliation of natural graphite to obtain graphene oxide, the graphene oxide dispersion of gained is prepared into the graphene oxide dispersion liquid that the concentration of graphene is 3mg / mL;

[0034] (2) Add reducing agent ethylenediamine solution to the graphene oxide dispersion, soak and wash for 2-7d, mix and reduce at 70°C for 10h to obtain graphene oxide hydrogel; the mass ratio of graphene oxide to reducing agent is 1:1;

[0035] (3) Soak and wash the obtained hydrogel with water or ethanol-water solution, then perform supercritical drying, the operating pressure is 9-12MPa, the temperature is 50-60°C, CO 2 The flow rate is 0.5-0.7L / h, and the drying time is 4-6h to obtain graphene airgel;

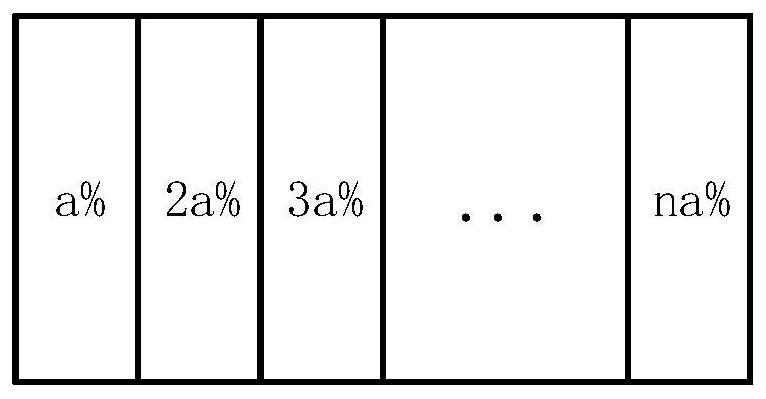

[0036] (4) The obtained graphene airgel is subjected to gradient heat treatment, and the treatment conditions are: heat treatment at 200°C for 2h, then heat treatment at 250°C for 2h, then at 300°C for 1h, an...

Embodiment 2

[0039] (1) adopt hummer method to carry out oxidative intercalation exfoliation of natural graphite to obtain graphene oxide, and the graphene oxide dispersion of gained is prepared into the graphene oxide dispersion liquid that the concentration of graphene is 5 mg / mL;

[0040] (2) Add reducing agent ethylenediamine solution to the graphene oxide dispersion, soak and wash for 2-7d, mix and reduce at 55°C for 19h to obtain graphene oxide hydrogel; the mass ratio of graphene oxide to reducing agent is 1:8;

[0041] (3) Soak and wash the obtained hydrogel with water or ethanol-water solution, and then carry out supercritical drying, the operating pressure is 9.5MPa, the temperature is 50°C, CO2 The flow rate is 0.7L / h, and the drying time is 6h to obtain graphene airgel;

[0042] (4) The obtained graphene airgel is subjected to gradient heat treatment, and the treatment conditions are: heat treatment at 220°C for 2h, then heat treatment at 280°C for 1h, then at 340°C for 1h, and...

Embodiment 3

[0045] (1) adopt hummer method to carry out oxidative intercalation exfoliation of natural graphite to obtain graphene oxide, and the graphene oxide dispersion of gained is prepared into the graphene oxide dispersion liquid that the concentration of graphene is 8 mg / mL;

[0046] (2) Add reducing agent ethylenediamine solution to the graphene oxide dispersion, soak and wash for 2-7d, mix and reduce at 60°C for 15h to obtain graphene oxide hydrogel; the mass ratio of graphene oxide to reducing agent is 1:10;

[0047] (3) Soak and wash the obtained hydrogel with water or ethanol-water solution, then carry out supercritical drying, the operating pressure is 12MPa, the temperature is 60°C, CO 2 The flow rate is 0.5L / h, and the drying time is 4h to obtain graphene airgel;

[0048] (4) The obtained graphene airgel is subjected to gradient heat treatment, and the treatment conditions are: heat treatment at 250°C for 1 hour, then heat treatment at 300°C for 1 hour, then treatment at 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com