A propeller mold structure

A technology of propellers and casting molds, which is applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve problems such as cumbersome procedures, high difficulty, and complicated operations, and achieve the effects of reducing the difficulty of molding, improving strength, and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

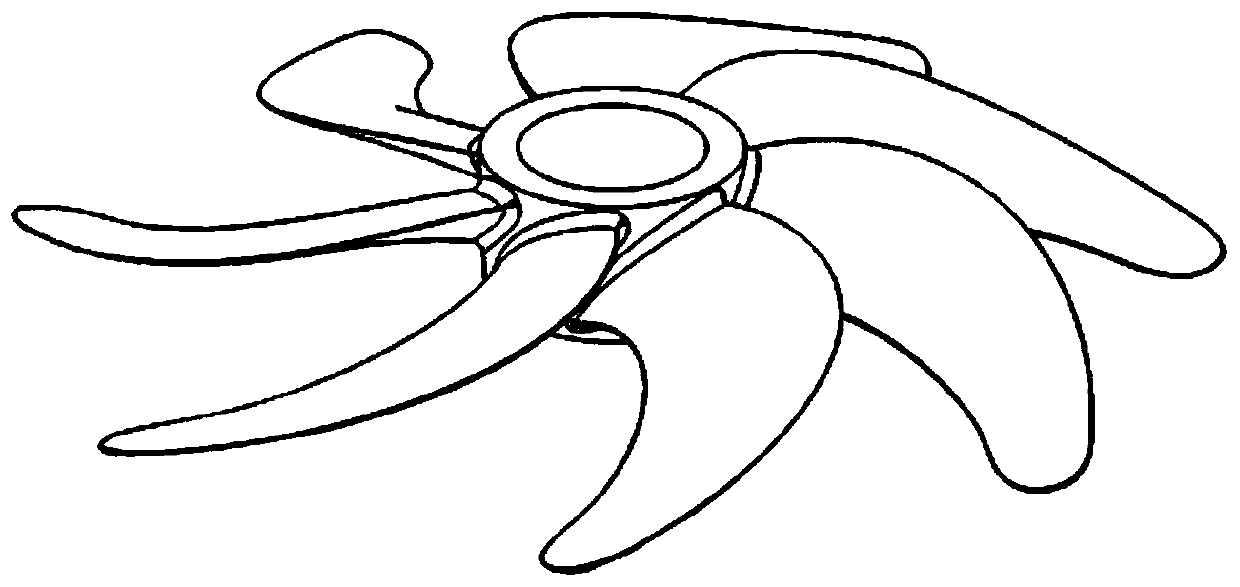

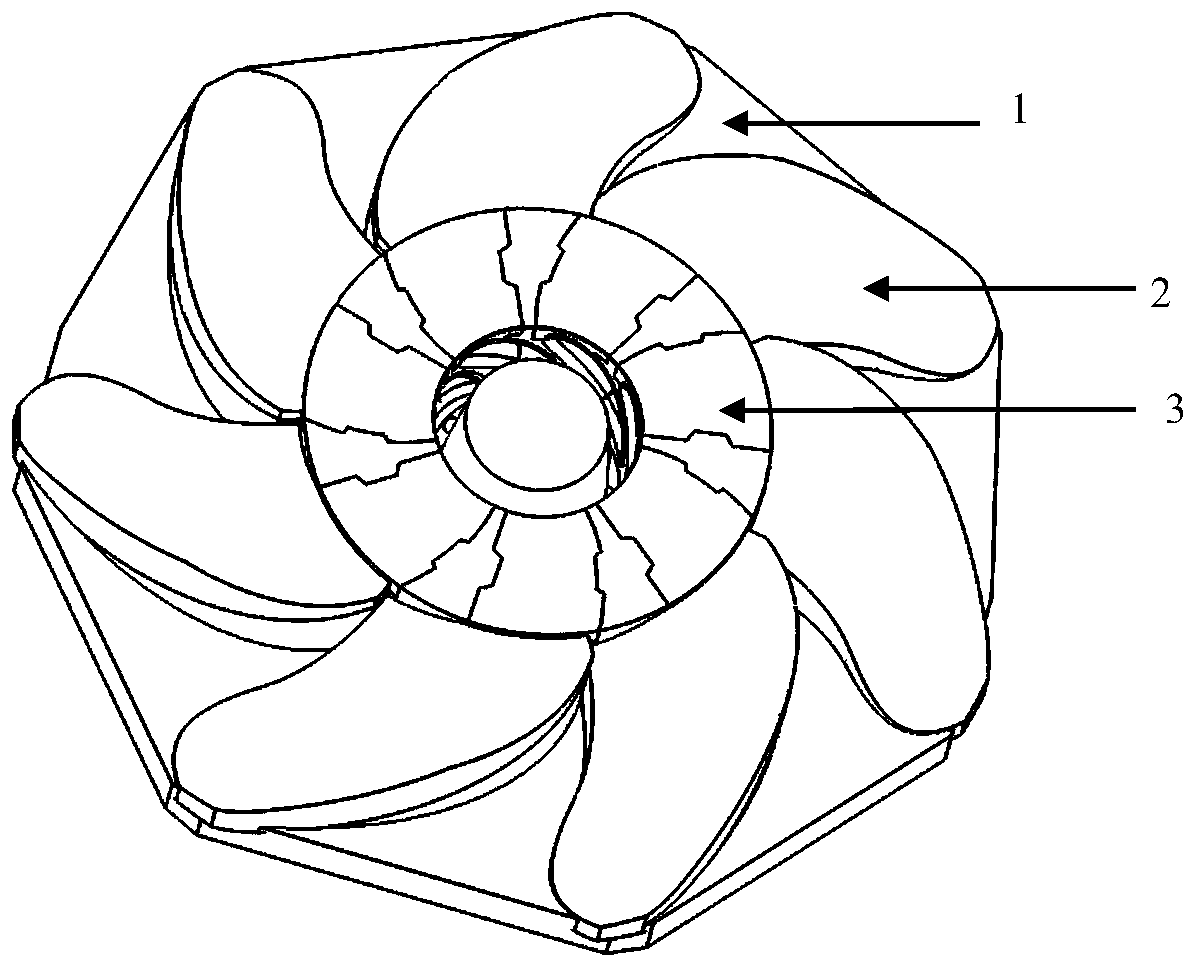

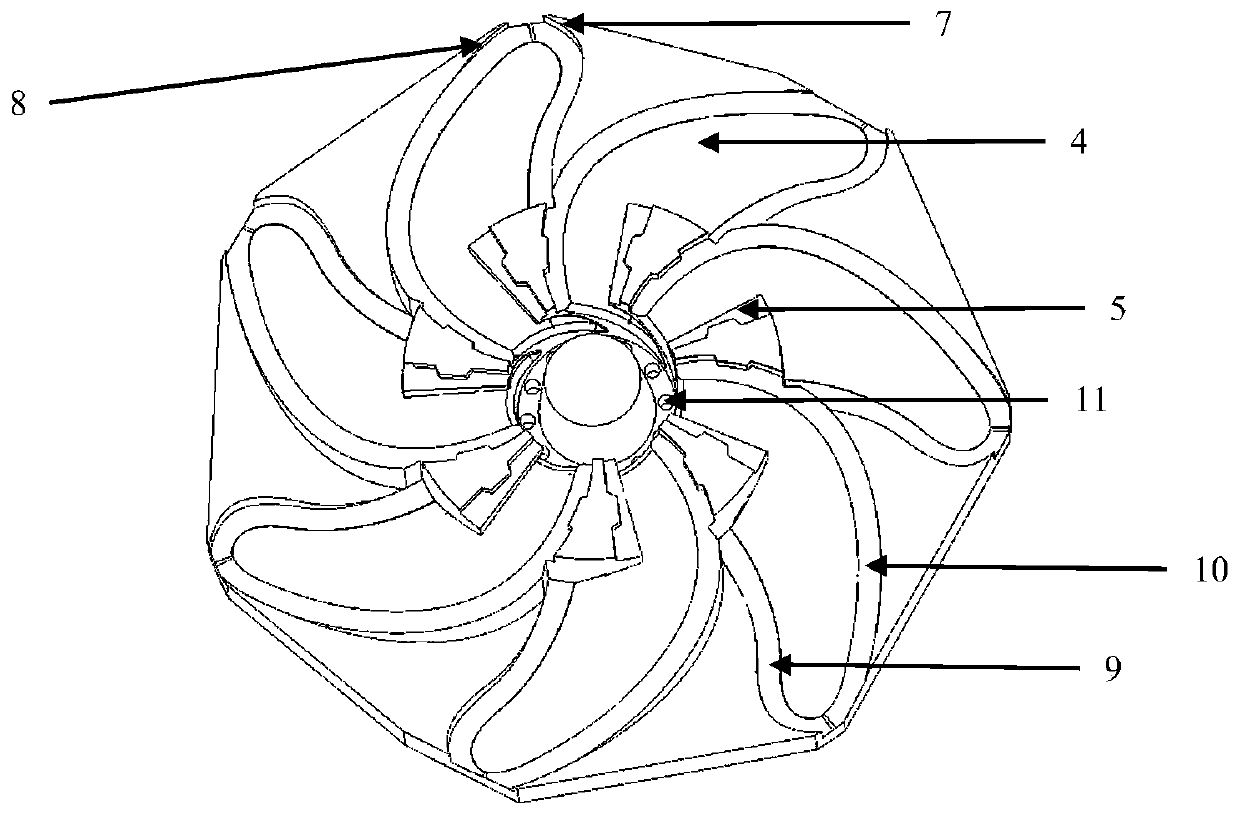

[0021] Technical scheme two of the present invention is attached figure 1 , 2 , 3, 4, including the following steps:

[0022] The lower form 1 includes the pressure surface 4 of the propeller mold, the positioning step 5, the part of the blade root suction surface starting from the follower, the pressure surface follower sidewall 7, the pressure surface lead sidewall 8, and the lead edge of the lower form. Profile surface 10, the edge parting surface 9 of the lower type, and the gate 11. The pressure surface 4 is arranged between the side wall 7 of the pressure surface and the side wall 8 of the pressure surface leading edge, and is located under the upper type A2 and the upper type B3 after being molded. The positioning step 5 is arranged between two adjacent upper forms B3. Part of the blade root suction surface 6 starting from the trailing edge is located below the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com