Mop washing bucket

A mop cleaning and bucket body technology, applied in the field of mops and mop cleaning buckets, can solve the problems of inconvenient operation, poor cleaning and squeezing effects, etc., and achieve the effects of wide application range, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

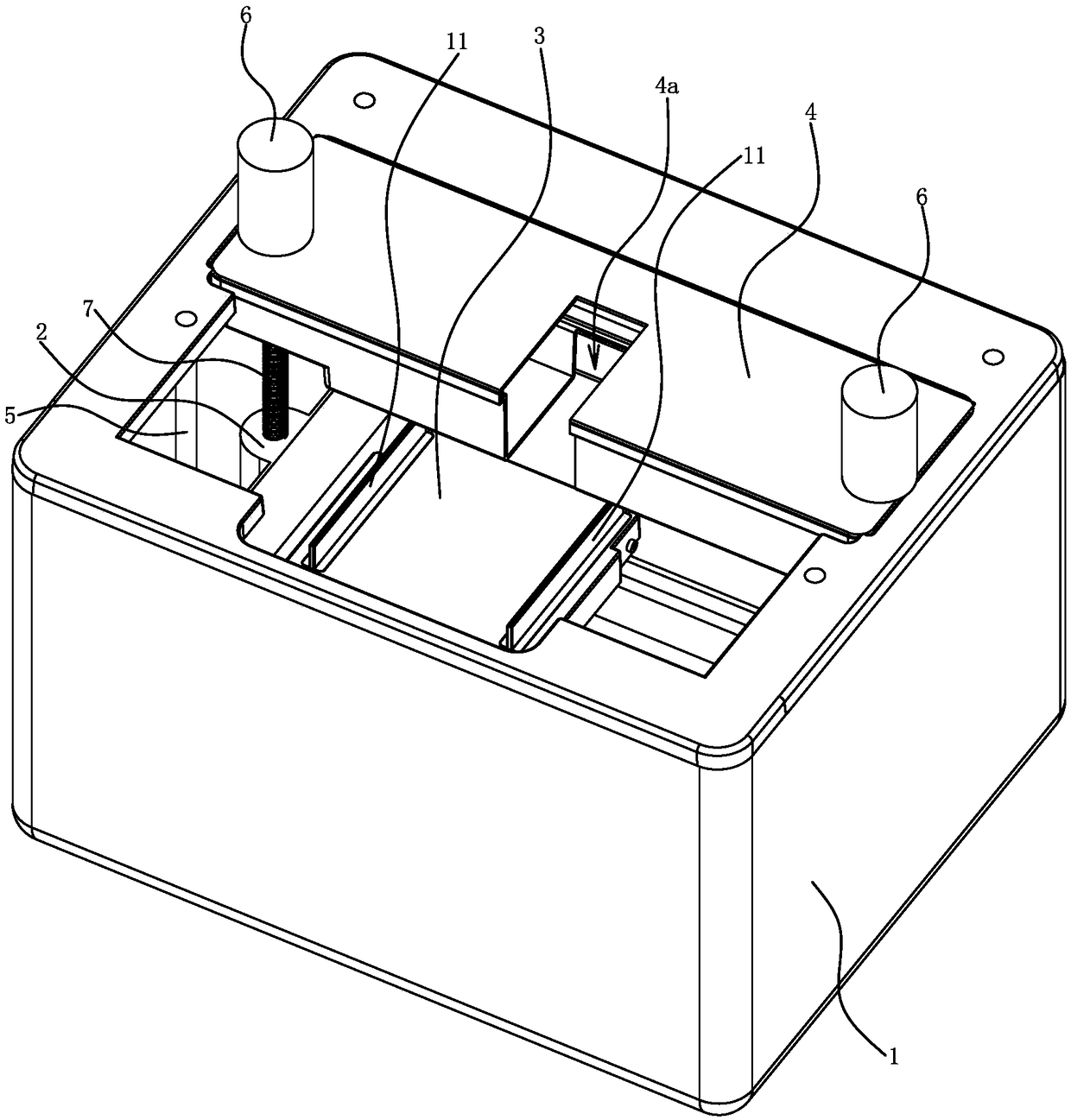

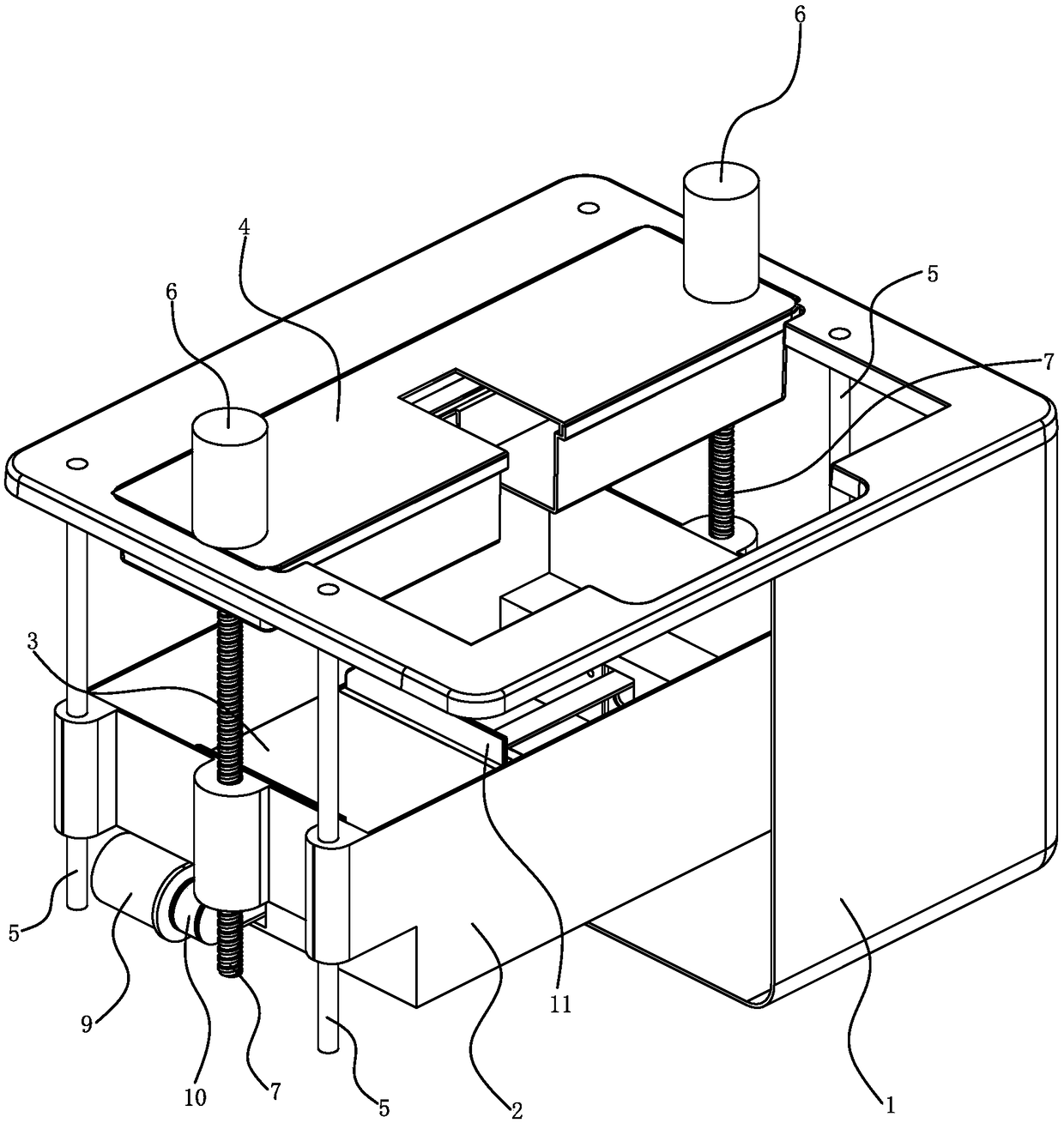

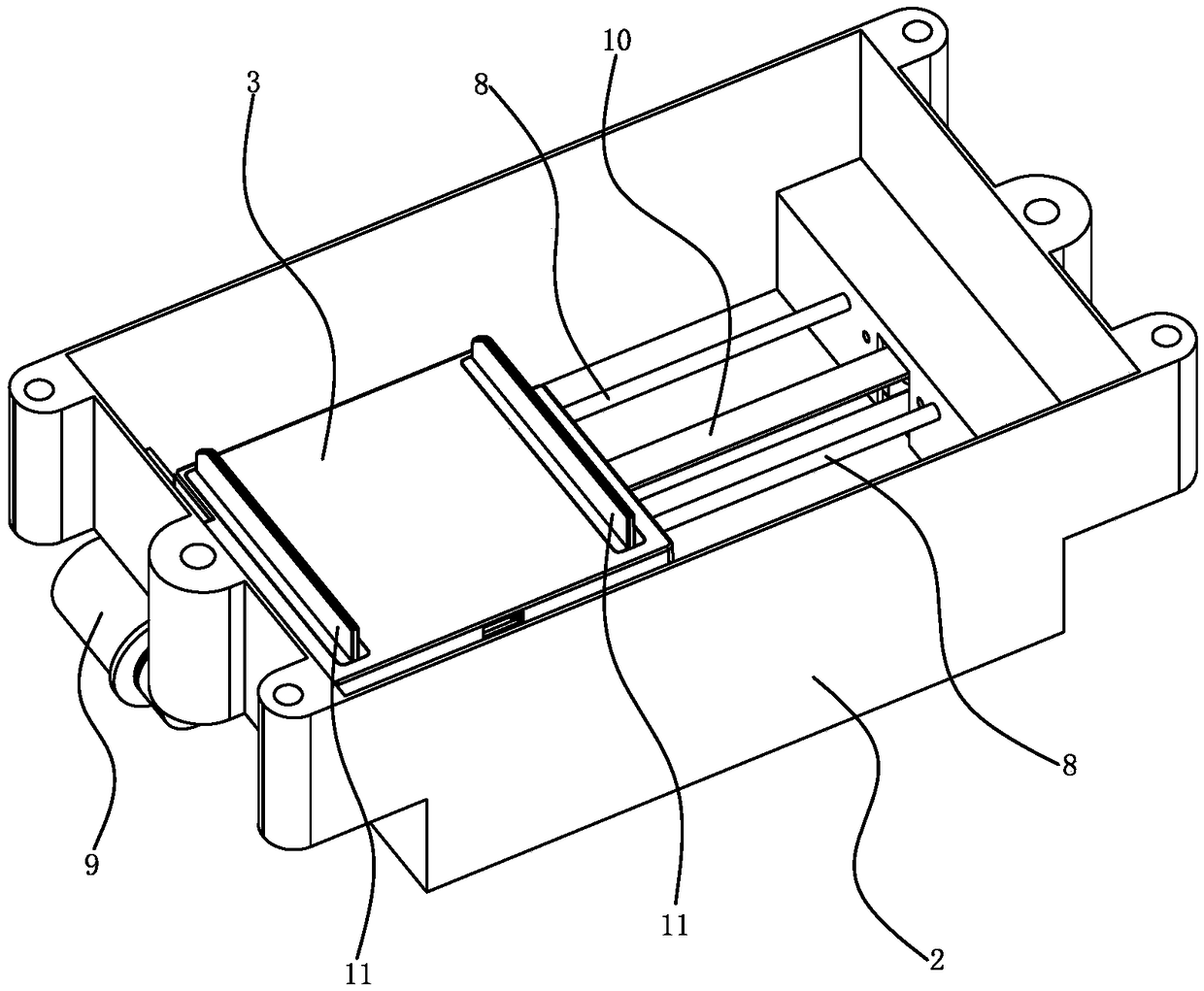

[0020] Such as Figure 1 to Figure 5 As shown, the mop cleaning bucket includes a bucket body 1, a lifting seat 2, a cleaning slider 3 and a water squeezing backer 4.

[0021] Lifting seat 2 is positioned at one side region of staving body 1 inner cavity, and squeeze water backing 4 is positioned at one side region of staving body 1 opening, and promptly squeezing water backing 4 is positioned at lifting seat 2 right above. The water squeeze backer 4 is installed on the barrel body 1; the water squeeze backer 4 and the barrel body 1 are connected by a buckle structure, or the water squeeze backer 4 and the barrel body 1 are fixedly connected by screws. The working head of the mop can be put into the barrel body 1 from the other side area of the barrel body 1 opening; there is an avoidance space 4a for the mop handle 15 to be placed on the water squeezing backer 4, and the working head can be placed on the mop by moving the mop horizontally. Lift seat 2 on.

[0022] Between...

Embodiment 2

[0031] Such as Figure 6 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1. The basic similarities will not be described redundantly, and only the differences will be described. The difference is that the water squeeze roller 12 is used to replace the wiper blade 11. The water roller 12 is rotatably connected with the cleaning slider 3 .

Embodiment 3

[0033] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The basic similarities will not be described redundantly. Only the differences will be described. The water backer 4 is installed on the lifting seat 2; the squeeze water backing 4 is connected with the lifting seat 2 as a whole or fixedly connected by screws. Squeeze water backer 4 is positioned at the side of lift seat 2, and the longitudinal line of wiper blade 11 is vertically arranged.

[0034] When using this mop cleaning bucket to clean the flat mop cleaning part 13, the working head is embedded between the lifting seat 2 and the wiper board 11, and the back side of the back plate 14 in the working head is against the water-squeezing backer 4, and the cleaning part 13 of the working head Abut against the wiper blade 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com