Coaxial cable and manufacturing method thereof

A flat cable and coaxial cable technology, applied in the direction of flat/ribbon cable, cable/conductor manufacturing, fixed connection, etc., can solve the problems of central conductor connection of coaxial flat cable, insufficient fastening strength of cable 101, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0071] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

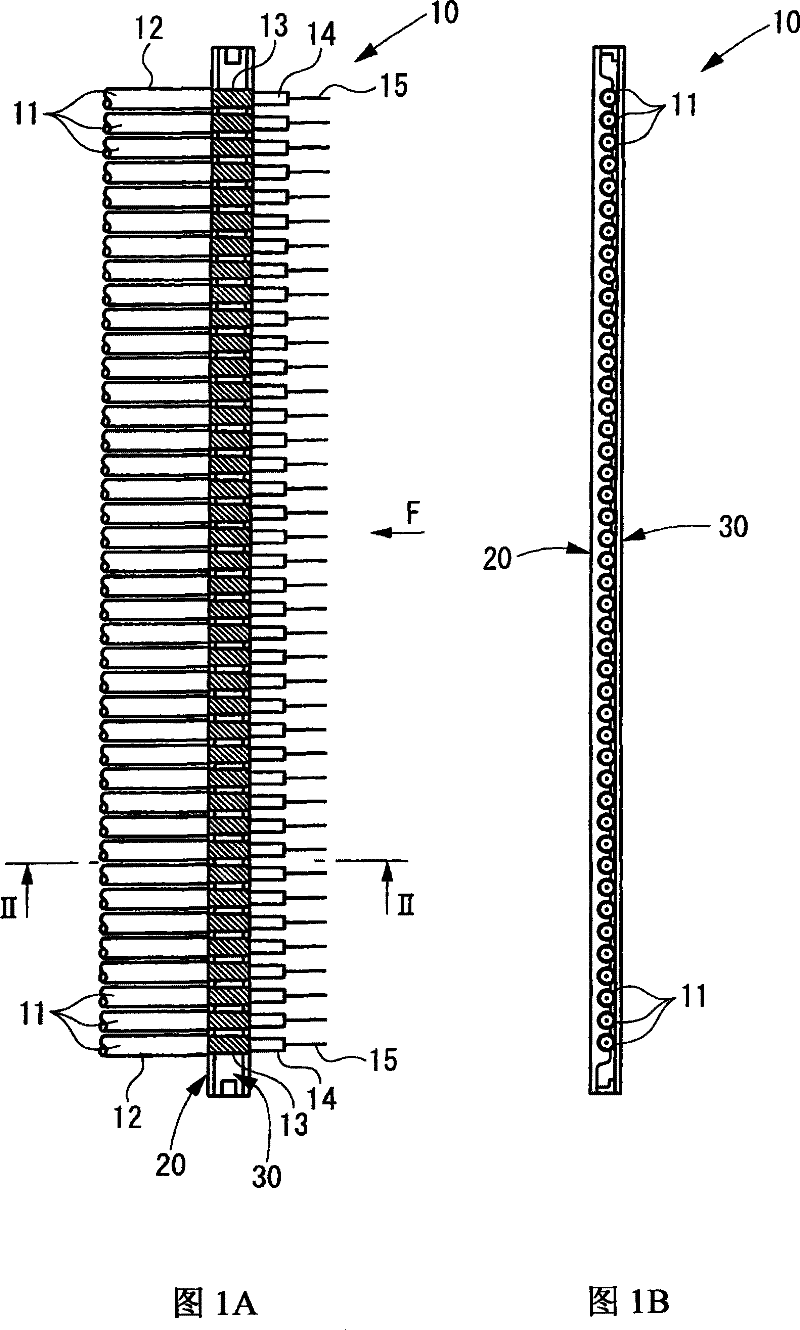

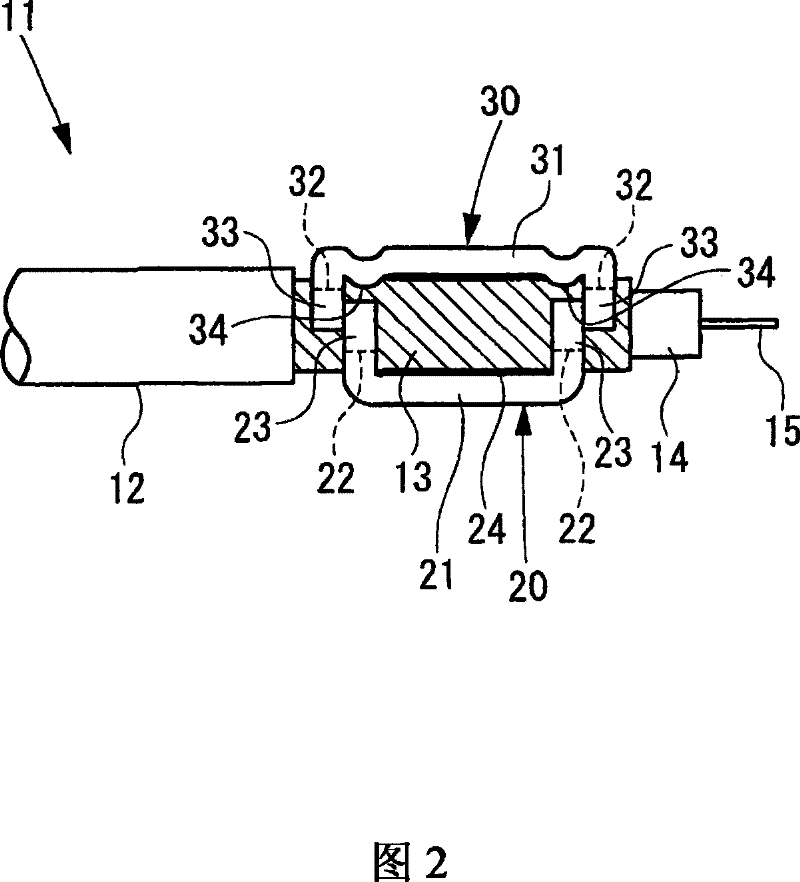

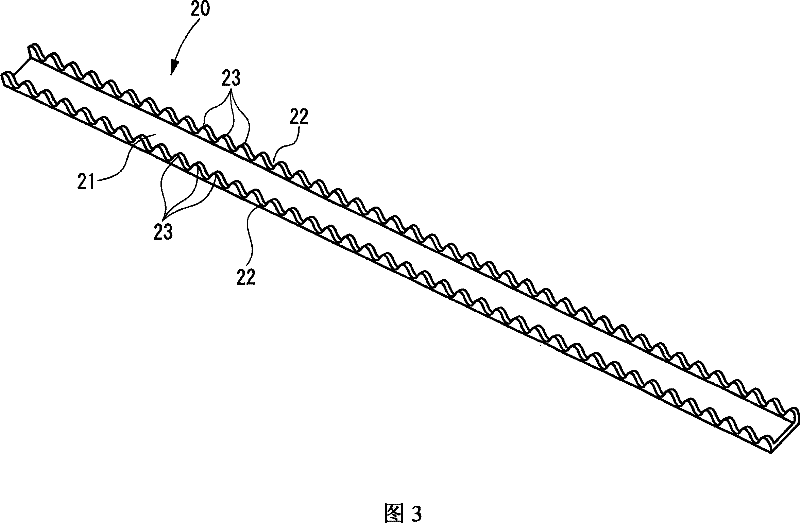

[0072] Fig. 1 shows a coaxial cable according to a first embodiment of the present invention. Figure 1A is the top view of the coaxial cable, Figure 1B From Figure 1A The side view seen from the F direction in . figure 2 is along Figure 1A The cross-sectional view taken on line II-II in and shows the end portion of the coaxial cable. image 3 It is the perspective view which removed the ground rod of the end. Figure 4 It is the perspective view which removed the pressing part of the end. exist Figure 1A In , the pressing member 30 (to be described below) is omitted to simplify the drawings.

[0073] As shown in FIG. 1, in the coaxial cable 10 according to the first embodiment of the present invention, a plurality of coaxial cables 11 are arranged in the horizontal direction. At the end portion of each coaxial cable 11 , the end port...

no. 2 example

[0099] Figure 10A is a plan view of a coaxial flat cable according to a second embodiment of the present invention, Figure 10B is along Figure 10A The side view seen from the F direction in . Figure 11 is a cross-sectional view of an exemplary coaxial cable. Figure 12A and Figure 12B is a cross-sectional view of an insulating covering member having a groove and a spacer, respectively. Figure 13 It is a plan view showing the state where the terminal portion of the central conductor is connected to the terminal.

[0100] Such as Figure 10A and Figure 10B As shown, in the coaxial flat cable 210A according to the second embodiment of the present invention, a plurality of coaxial cables 211A are arranged in parallel to each other. Their ends are subjected to internal member exposing processing; that is, portions having predetermined lengths of center conductor 212A, insulator 213A, and outer conductor 214A of each coaxial cable 211A are sequentially exposed from the...

no. 3 example

[0114] Next, a coaxial flat cable according to a third embodiment of the present invention and its manufacturing method will be described.

[0115] Figure 14 is a perspective view of a coaxial flat cable according to a third embodiment of the present invention. Figure 15A is a top view of a coaxial flat cable, Figure 15B is along Figure 15A A cross-sectional view taken along line B-B in . Figure 16A to Figure 16C are a plan view and a cross-sectional view showing a method of manufacturing a coaxial flat cable according to a third embodiment of the present invention as process diagrams.

[0116] Such as Figure 14 As shown in FIG. 15, in a coaxial flat cable 210 according to a third embodiment of the present invention, at each end portion of a plurality of coaxial cables 211 arranged in parallel to each other, a center conductor 212, an insulator 213 and an outer conductor Parts of 214 are sequentially exposed from the outer sheath 215 in a stepped manner. Ground rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com