Construction method of fabricated under-crossing tunnel

A construction method and prefabricated technology, which can be applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of long construction period of underpass tunnels, achieve the effects of speeding up the assembly progress, stabilizing the support, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

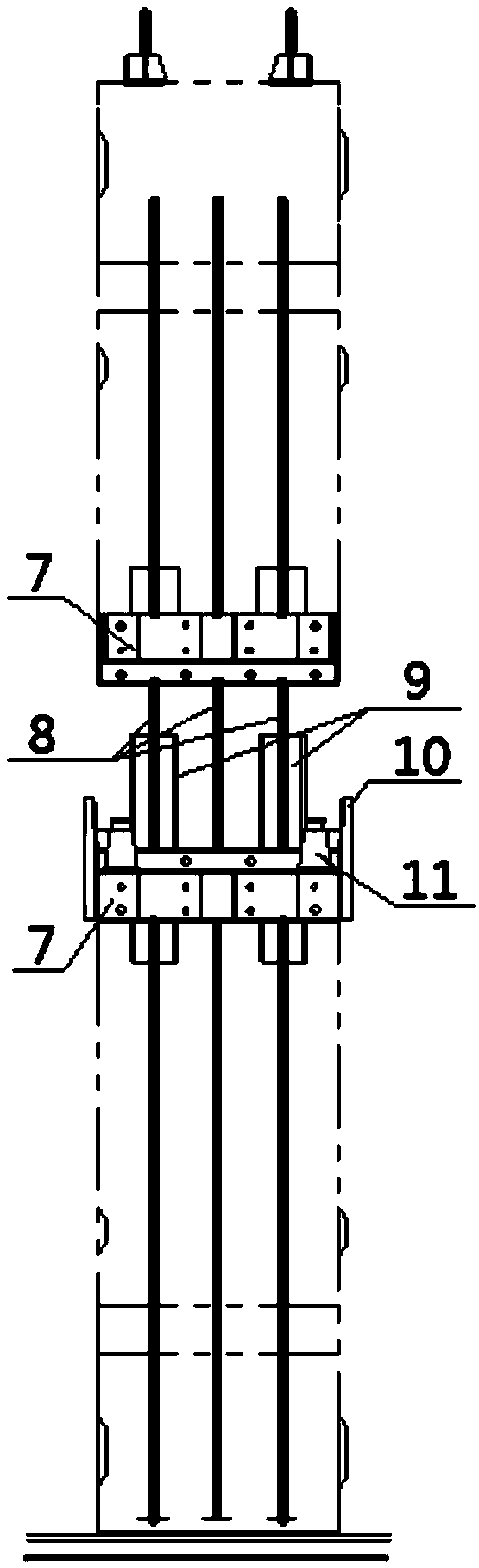

Image

Examples

Embodiment

[0043] This embodiment provides a construction method for an assembled underpass tunnel;

[0044] The construction method of the assembled underpass tunnel in this embodiment includes the following steps:

[0045] a. Construct a concrete foundation at the bottom of the foundation pit, and install steel rails extending longitudinally along the tunnel at the position corresponding to the vertical wall of the tunnel;

[0046] b. After the bottom plate 1 is hoisted to the rail and placed in place, the top plate 2 is lifted to align above the bottom plate and dropped into place, and the bottom plate and the top plate are connected and assembled into a ring to form a single tunnel segment;

[0047] c. After assembling the subsequent segments into a ring, push them until they fit together with the end face of the previous segment. When the number of segments reaches a certain amount, perform longitudinal permanent prestressing on multiple segments to form a hole segment 28;

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com